Aluminum alloy subjected to composite microalloying of Sc and Zr and preparation method thereof

A technology of microalloying and aluminum alloy, applied in Zr composite microalloying aluminum alloy and preparation, microalloying aluminum alloy and preparation, using Sc field, can solve the problem that tensile strength and yield strength are not particularly obvious, strengthening effect It can improve the recrystallization temperature and thermal stability, increase the fatigue strength and fatigue life, and improve the comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

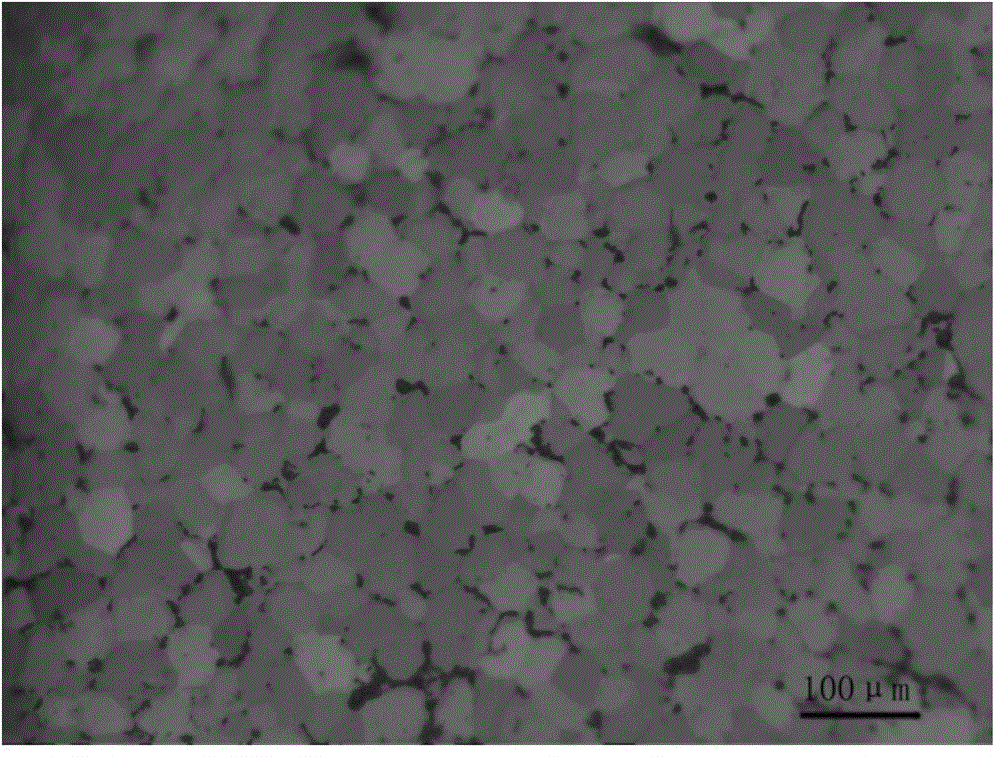

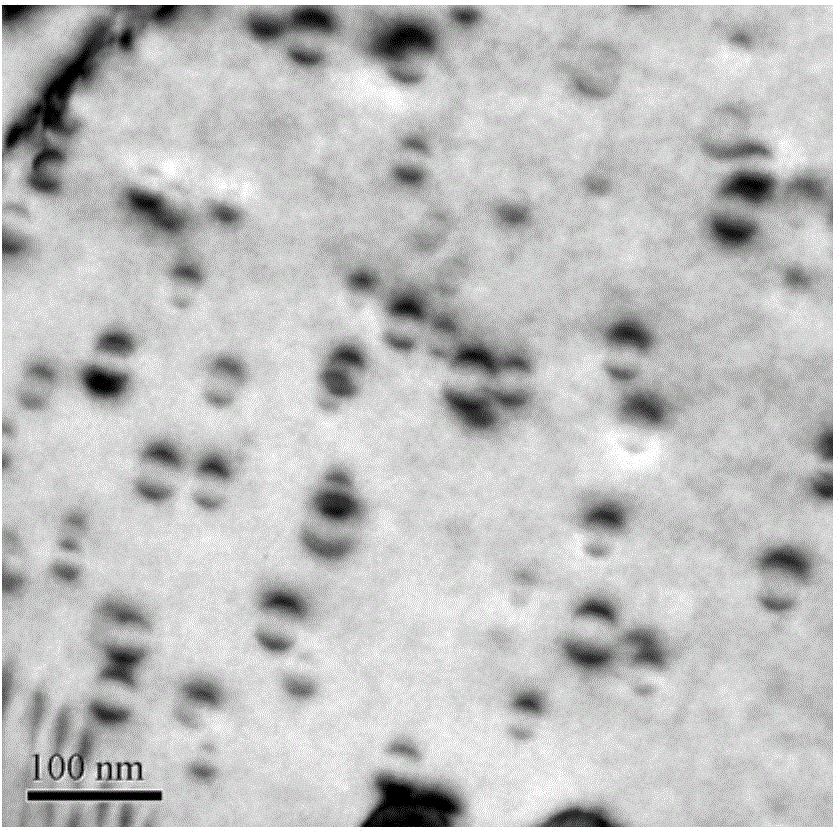

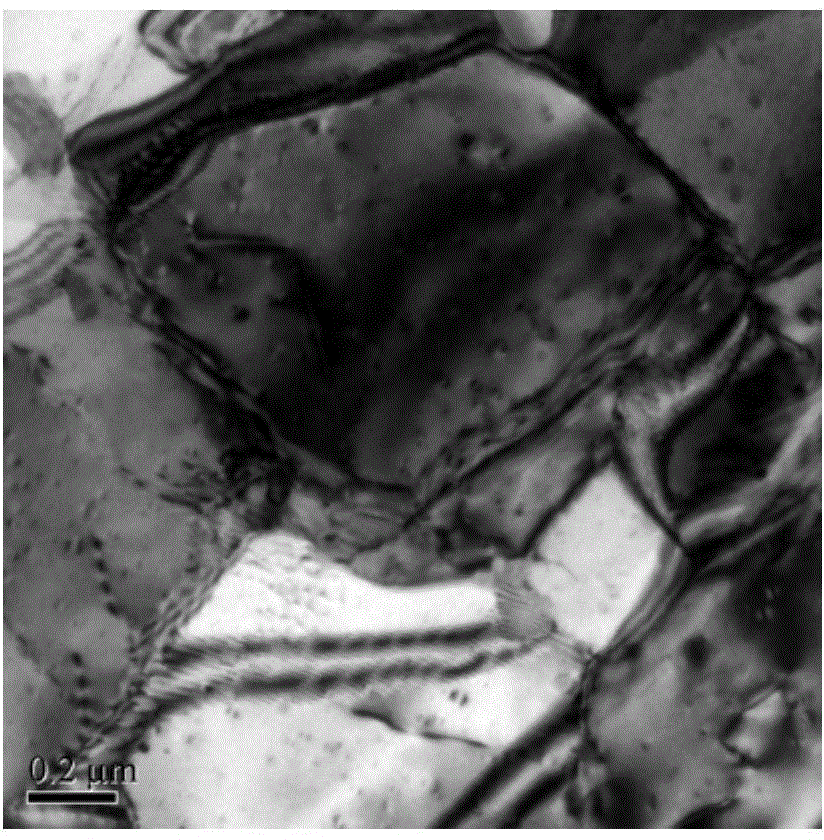

Embodiment 1

[0034] Al-8.5% Mn master alloy accounting for 5% of the total weight of the alloy, 11.8% Al-2.2% Sc master alloy, 2.3% Al-4.5% Zr master alloy, 6.1% pure Mg, and the balance is pure Al. Smelting by ingot metallurgy, KCl as covering agent, C 6 Cl 6 As a degasser, it is melted into an alloy ingot with the composition of Al-5.8Mg-0.4Mn-0.25Sc-0.1Zr (alloy C) in a crucible resistance furnace. The ingot is homogenized at 460°C-470°C for 24 hours, then cut and milled, and then hot-rolled at 420°C-430°C for 3 hours to form a 6mm thick plate. The hot-rolled plate is cold-rolled after intermediate annealing into 2mm thick plates. After the cold-rolled sheet was stabilized and annealed at 350°C for 1 hour, its mechanical properties at room temperature were measured. The results are shown in Table 1.

[0035]Smelting and rolling Al-5.8Mg-0.4Mn (alloy A) and Al-5.8Mg-0.4Mn-0.25Sc (alloy B) by the same preparation method, annealing at 350 ° C for 1 hour, and then measuring their room te...

Embodiment 2

[0037] Using Al-8.5%Mn master alloy accounting for 5% of the total weight of the alloy, 9.4% Al-2.2%Sc master alloy, 4.6% Al-4.5%Zr master alloy, 6.4% pure Mg, and the balance is pure Al. Smelting by ingot metallurgy, KCl as covering agent, C 6 Cl 6 As a degasser, it is melted in a crucible resistance furnace to form an alloy ingot with a composition of Al-6Mg-0.4Mn-0.2Sc-0.2Zr (alloy D). The ingot is homogenized at 460°C-470°C for 24 hours, then cut and milled, and then hot-rolled at 420°C-430°C for 3 hours to form a 6mm thick plate. The hot-rolled plate is cold-rolled after intermediate annealing into 2mm thick plates. After the cold-rolled sheet was stabilized and annealed at 350°C for 1 hour, its mechanical properties at room temperature were measured. The results are shown in Table 1 for Alloy D.

Embodiment 3

[0039] Using 5% Al-8.5%Mn master alloy, 7% Al-2.2%Sc master alloy, 5.8% Al-4.5%Zr master alloy, 6.1% pure Mg, and the balance is pure Al, accounting for 5% of the total weight of the alloy. Smelting by ingot metallurgy, KCl as covering agent, C 6 Cl 6 As a degasser, it is melted into an alloy ingot with the composition of Al-5.8Mg-0.4Mn-0.15Sc-0.25Zr (alloy E) in a crucible resistance furnace. The ingot is homogenized at 460°C-470°C for 24 hours, then cut and milled, and then hot-rolled at 420°C-430°C for 3 hours to form a 6mm thick plate. The hot-rolled plate is cold-rolled after intermediate annealing into 2mm thick plates. After the cold-rolled sheet was stabilized and annealed at 350°C / h, its mechanical properties at room temperature were measured. The results are shown in Table 1 for Alloy E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com