Method for preparing nano composite plating layer

A nanocomposite and coating technology, applied in coatings, electrolytic coatings, etc., can solve the problems of easy agglomeration of nanoparticles and achieve the effect of improving wetting conditions, uniform and fine grains, and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

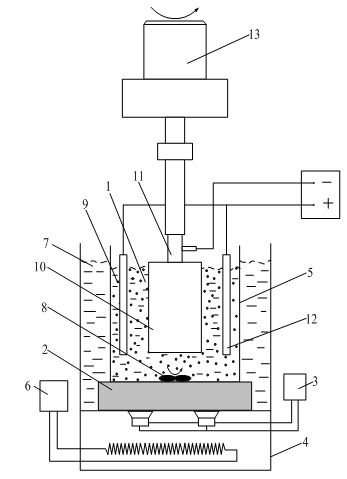

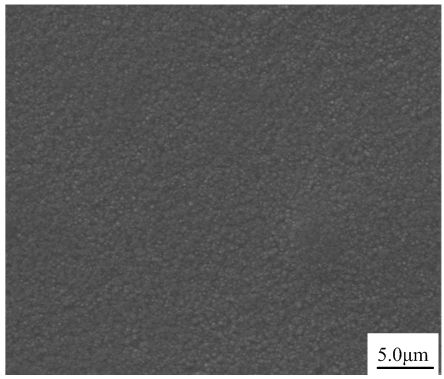

Method used

Image

Examples

Embodiment 1

[0040] 1) Select the cathode and anode substrate for plating

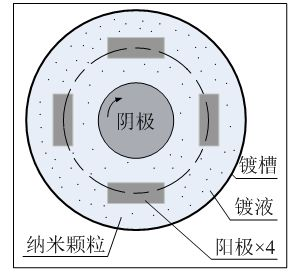

[0041] In the test, the side surface of a stainless steel cylinder with a diameter of Φ20mm is used as the working surface of the plating cathode, and 4 electrolytic nickel plates with a purity greater than 99.99% are used as the anode. The volume specification of the nickel plate is 150mm×30mm×3mm, and 4 pieces of nickel The plates are uniformly distributed around the cathode, and the ratio of the area of the immersion liquid cathode to the anode is 1:6. The operation process of the surface treatment of the cathode stainless steel cylinder is as follows: sanding with fine sandpaper to the mirror surface → repeated rubbing with alcohol to remove oil → about 10% sulfuric acid solution passivation of the plating surface for 1 hour → cleaning with distilled water → drying for use. The power device for the cathode rotation is an AC speed-regulating motor, and the power supply adopts a constant current stabilized power s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com