Anti-corrosion crusher hammerhead and preparation method thereof

A crusher and anti-corrosion technology, applied in manufacturing tools, heat treatment equipment, furnace types, etc., can solve problems such as low service life, and achieve the effects of improved yield strength, high hardness, and improved tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

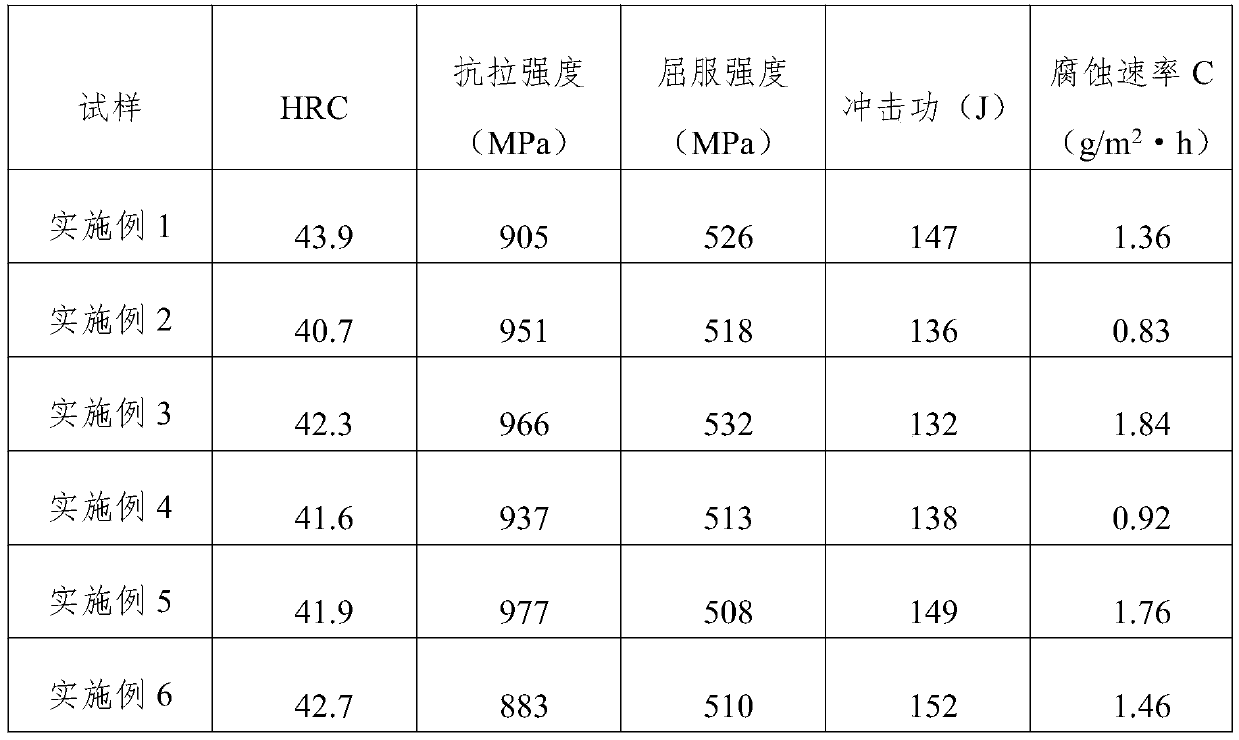

Examples

Embodiment 1

[0025] A corrosion-resistant crusher hammer head, comprising the following components in terms of mass percentage: Cr 20.68%, Ni8.64%, Nb 4.19%, Mo 1.58%, Mn 1.25%, C 2.04%, Si 0.10%, W 0.22%, V 0.12%, S0.01%, P 0.005%, and the rest are Fe and unavoidable impurities.

[0026] The preparation method of the corrosion-resistant crusher hammer specifically comprises the following steps:

[0027] S1. Smelting: Put scrap steel and pig iron into the medium frequency induction furnace for smelting, melt the molten steel, add ferrochrome, ferronickel, ferro-niobium, ferro-molybdenum, ferro-vanadium, ferro-tungsten, ferro-manganese and ferrosilicon, heat up and keep warm until completely melted , the smelting temperature is 1550°C, cover the slagging material, calm down, remove the slag, add aluminum accounting for 0.03% of the mass of all raw materials for deoxidation, and finally add rare earth for compound modification treatment to obtain molten steel;

[0028] S2, casting: when the...

Embodiment 2

[0032] A corrosion-resistant crusher hammer head, comprising the following components in terms of mass percentage: Cr 21.8%, Ni9.47%, Nb 5.62%, Mo 1.67%, Mn 1.38%, C 2.36%, Si 0.35%, W 0.29%, V 0.17%, S0.01%, P 0.005%, and the rest are Fe and unavoidable impurities.

[0033] The preparation method of the corrosion-resistant crusher hammer specifically comprises the following steps:

[0034] S1. Smelting: Put scrap steel and pig iron into the medium frequency induction furnace for smelting, melt the molten steel, add ferrochrome, ferronickel, ferro-niobium, ferro-molybdenum, ferro-vanadium, ferro-tungsten, ferro-manganese and ferrosilicon, heat up and keep warm until completely melted , the smelting temperature is 1610°C, cover the slagging material, calm down, remove the slag, add aluminum accounting for 0.03% of the mass of all raw materials for deoxidation, and finally add rare earth for compound modification treatment to obtain molten steel;

[0035] S2, casting: when the ...

Embodiment 3

[0039]A corrosion-resistant crusher hammer head, comprising the following components in terms of mass percentage: Cr 23.20%, Ni 10.32%, Nb 6.08%, Mo 1.84%, Mn 1.57%, C 2.65%, Si 0.43%, W 0.37%, V 0.23%, S0.01%, P 0.005%, and the rest are Fe and unavoidable impurities.

[0040] The preparation method of the corrosion-resistant crusher hammer specifically comprises the following steps:

[0041] S1. Smelting: Put scrap steel and pig iron into the medium frequency induction furnace for smelting, melt the molten steel, add ferrochrome, ferronickel, ferro-niobium, ferro-molybdenum, ferro-vanadium, ferro-tungsten, ferro-manganese and ferrosilicon, heat up and keep warm until completely melted , the smelting temperature is 1680°C, cover the slagging material, calm down, remove the slag, add aluminum accounting for 0.03% of the mass of all raw materials for deoxidation, and finally add rare earth for compound modification treatment to obtain molten steel;

[0042] S2, casting: when th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com