Forging method for superconducting tantalum bar

A superconducting and drop-weight forging technology, which is applied in the forging field of superconducting tantalum rods, can solve problems such as broken wires, affecting superconducting performance, and low degree of broken microstructure in the as-cast state, and achieve the effect of improving the degree of inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

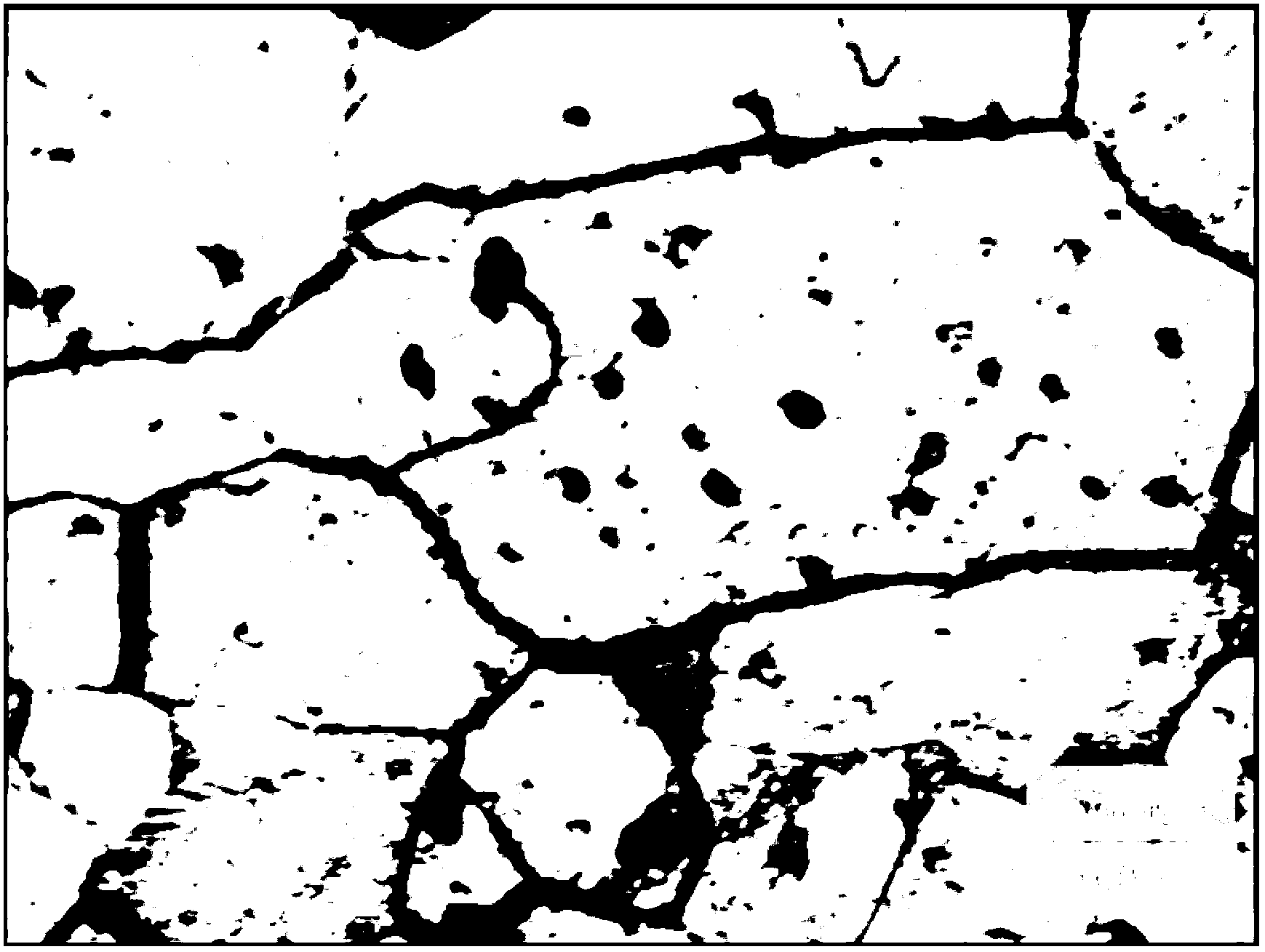

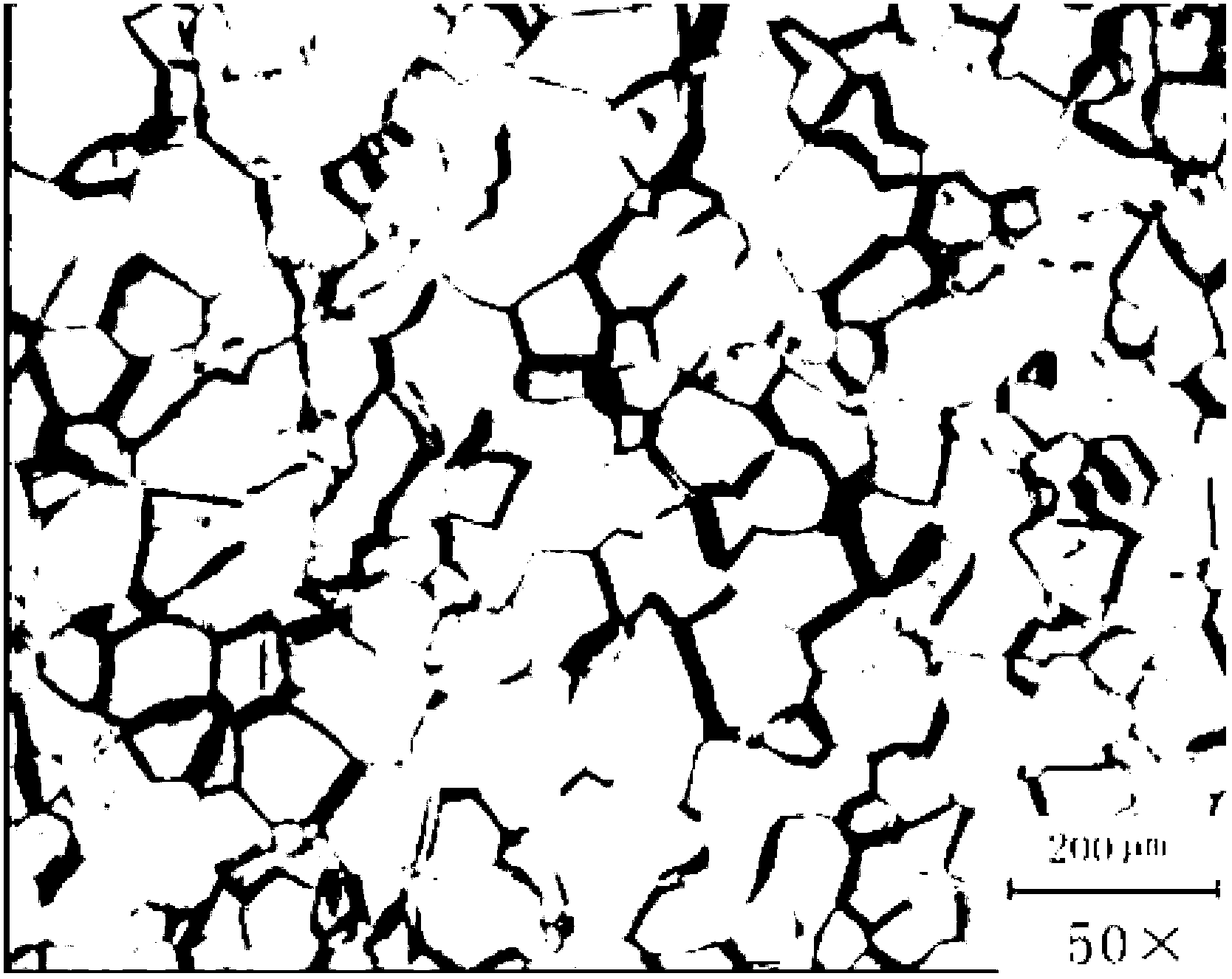

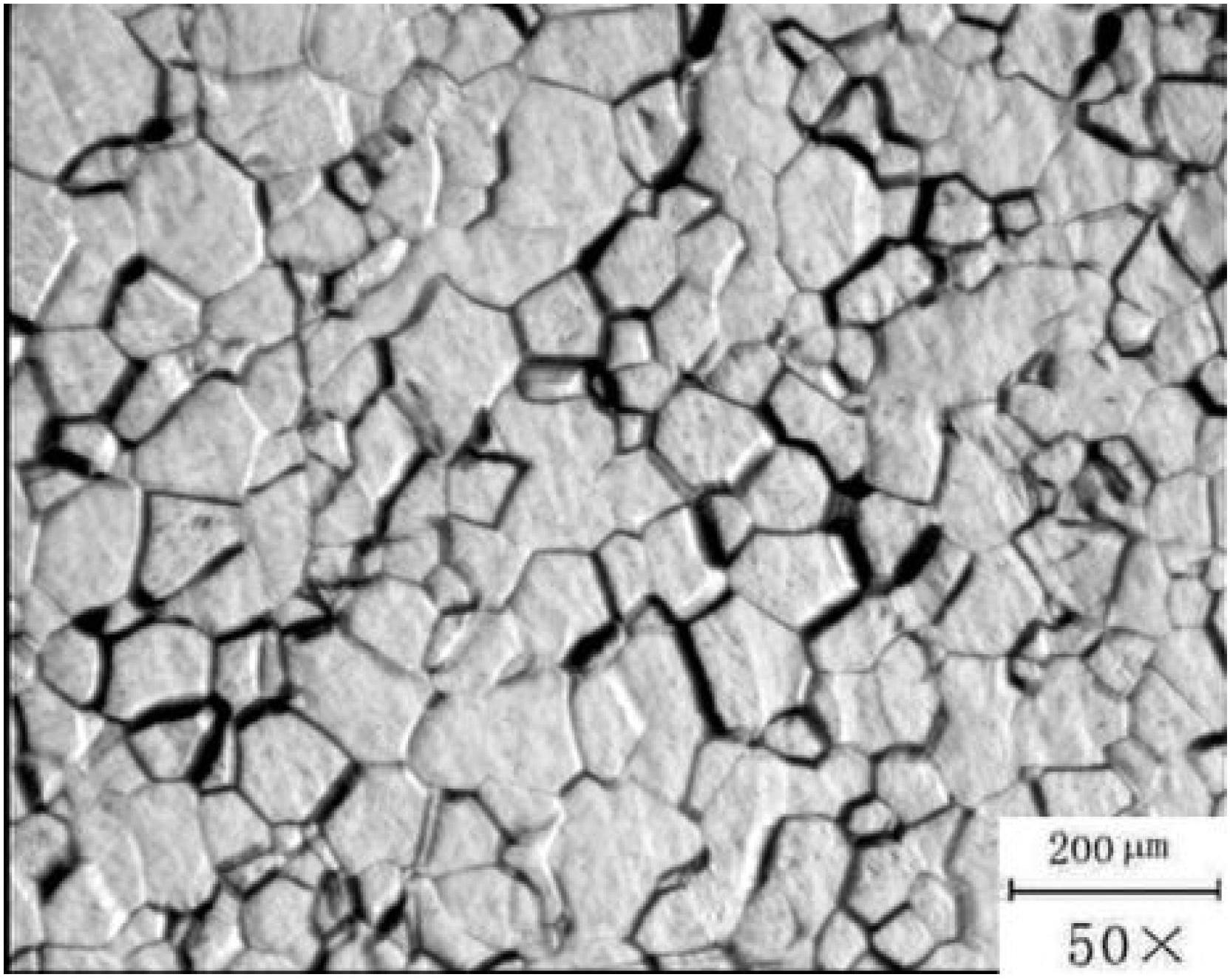

Image

Examples

Embodiment 1

[0018] (1) Ingot (outer circle diameter × length) φ153×250mm, the chemical composition of the ingot meets the requirements shown in Table 1:

[0019] Table 1: Chemical composition of superconducting tantalum and niobium Not greater than, wt%

[0020] the element

C

O

N

H

Nb

W

standard requirement

0.002

0.0045

0.004

0.0005

0.005

0.005

actual data

0.0005

0.003

0.0018

0.0002

0.003

0.0018

the element

Ti

Mo

Si

Fe

Ni

Ta

standard requirement

0.002

0.002

0.002

0.002

0.002

99.9

actual data

0.0001

0.001

0.001

0.0003

0.0003

99.97

[0021] (2) Preheating, the heating temperature is 180°C, and the holding time is 25 minutes.

[0022] (3) Use a coating material that is uniformly stirred and mixed in the ratio of low-temperature glass powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com