Anti-bacterial dual-phase stainless steel and machining process thereof

A technology of duplex stainless steel and processing technology, which is applied in the field of duplex stainless steel, can solve the problems of high nickel content and high price, and achieve the effects of improving corrosion resistance, antibacterial performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

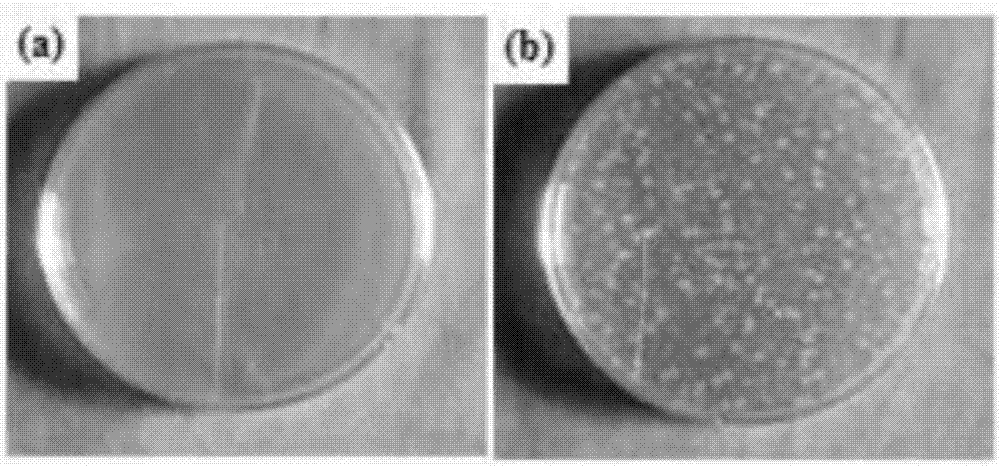

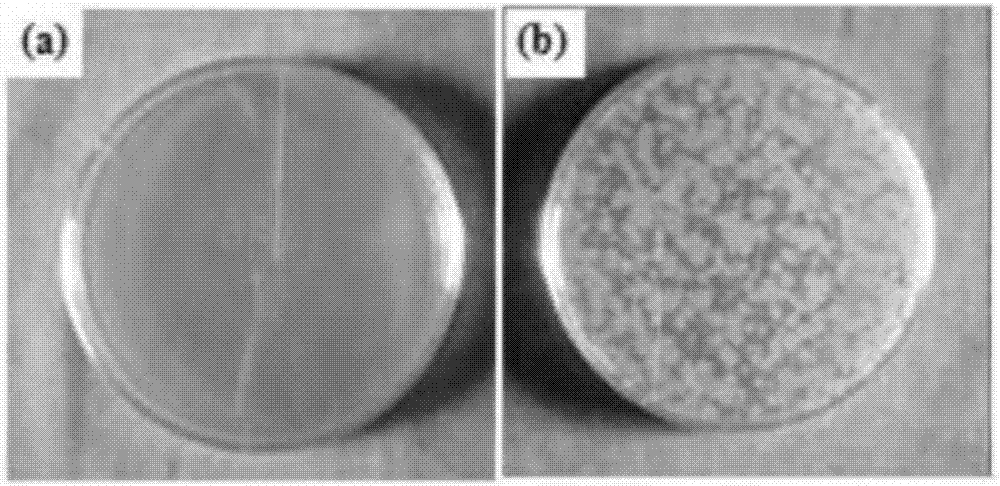

Image

Examples

Embodiment 1

[0051] The antibacterial duplex stainless steel provided in the first embodiment includes the following components by mass percentage:

[0052] C: 0.02%;

[0053] Si: 0.58%;

[0054] Mn: 4.37%;

[0055] S: 0.005%;

[0056] P: 0.015%;

[0057] Cr: 14.32%;

[0058] Mo: 1.47%;

[0059] W: 0.30%;

[0060] B: 0.012%;

[0061] Cu: 2.38%;

[0062] Ag: 0.009%;

[0063] Nb: 0.023%;

[0064] N: 0.31%;

[0065] Ba: 0.05%;

[0066] Mixed rare earth: 0.011%;

[0067] Fe margin.

[0068] Further, in this embodiment 1, the mixed rare earth is lanthanum-cerium mixed rare earth; in the lanthanum-cerium mixed rare earth, La≤45% and Ce≤51%; in the lanthanum-cerium mixed rare earth, there is also La and Ce The total content is greater than or equal to 99.7%; the lanthanum-cerium mixed rare earth also contains one or more rare earth elements of praseodymium, neodymium, promethium, and samarium.

[0069] The processing technology of antibacterial duplex stainless steel provided in the first embodiment includes the follo...

Embodiment 2

[0079] The antibacterial duplex stainless steel provided by the second embodiment includes the following components by mass percentage:

[0080] C: 0.019%;

[0081] Si: 0.87%;

[0082] Mn: 5.52%;

[0083] S: 0.005%;

[0084] P: 0.015%;

[0085] Cr: 16.55%;

[0086] Mo: 1.72%;

[0087] W: 0.48%;

[0088] B: 0.013%;

[0089] Cu: 2.76%;

[0090] Ag: 0.015%;

[0091] Nb: 0.041%;

[0092] N: 0.39%;

[0093] Ba: 0.08%;

[0094] Mixed rare earth: 0.018%;

[0095] Fe margin.

[0096] Further, in this embodiment 2, the mixed rare earth is a lanthanum-cerium mixed rare earth; in the lanthanum-cerium mixed rare earth, La≤45% and Ce≤51%; in the lanthanum-cerium mixed rare earth, there is also La and Ce The total content is greater than or equal to 99.7%; the lanthanum-cerium mixed rare earth also contains one or more rare earth elements of praseodymium, neodymium, promethium and samarium.

[0097] The processing technology of antibacterial duplex stainless steel provided in the second embodiment includes the f...

Embodiment 3

[0107] The antibacterial duplex stainless steel provided in the third embodiment includes the following components by mass percentage:

[0108] C: 0.017%;

[0109] Si: 1.02%;

[0110] Mn: 7.45%;

[0111] S: 0.004%;

[0112] P: 0.013%;

[0113] Cr: 18.28%;

[0114] Mo: 2.62%;

[0115] W: 0.63%;

[0116] B: 0.016%;

[0117] Cu: 3.10%;

[0118] Ag: 0.009%;

[0119] Nb: 0.056%;

[0120] N: 0.48%;

[0121] Ba: 0.010%;

[0122] Mixed rare earth: 0.029%;

[0123] Fe margin.

[0124] Further, in Example 3, the mixed rare earth is lanthanum-cerium mixed rare earth; in the lanthanum-cerium mixed rare earth, La≤45% and Ce≤51%; in the lanthanum-cerium mixed rare earth, there is also La and Ce The total content is greater than or equal to 99.7%; the lanthanum-cerium mixed rare earth also contains one or more rare earth elements of praseodymium, neodymium, promethium and samarium.

[0125] The processing technology of antibacterial duplex stainless steel provided in the third embodiment includes the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com