Method of using composite extracting agent for extraction and refining of phosphoric acid prepared through wet process

A composite extraction agent, wet phosphoric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high extraction ortho acid, poor extraction effect, high production cost, low production cost and simplified operation. , requires less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

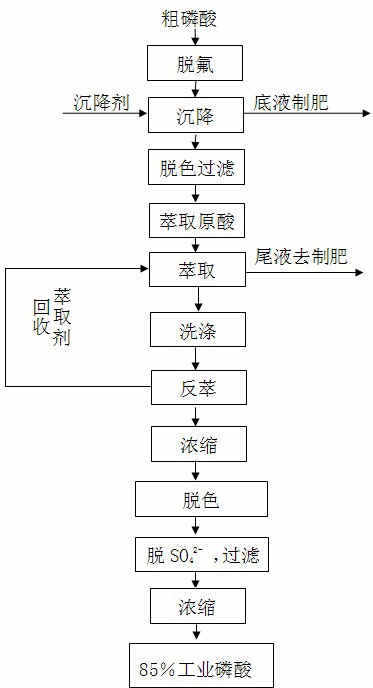

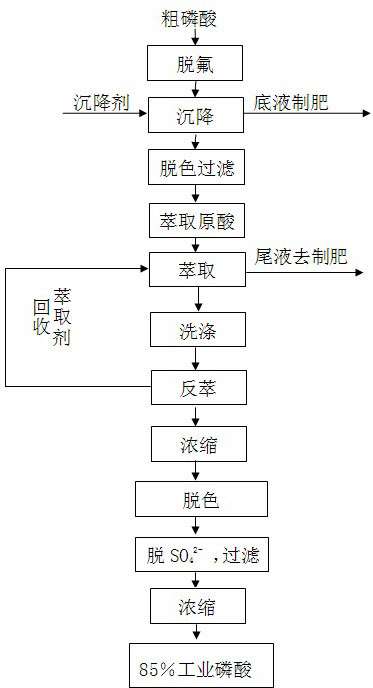

[0061] A method for extracting and refining wet-process phosphoric acid with a compound extractant, the method comprises the following processes in sequence:

[0062] Pretreatment process: first concentrate the crude phosphoric acid obtained by the wet method until the P in the crude phosphoric acid 2 o 5 The mass percentage concentration is 45%, and Na is added to the crude phosphoric acid after concentration 2 CO 3 For defluorination, the Na 2 CO 3 The amount of the added amount is calculated according to 100%–120% of the free fluoride ion stoichiometry in the concentrated crude phosphoric acid, and then the compound sedimentation agent is added to the crude phosphoric acid after defluorination for sedimentation, and then stirred evenly, and the sedimentation can be obtained after 4 hours of sedimentation Cleaning acid and bottom flow slag acid, the volume of the sedimentation cleaning acid is 85%-90% of the sum of the volume of the crude phosphoric acid after defluorina...

Embodiment 2

[0070] Step is with embodiment 1, and difference is:

[0071] Extraction and refining process: Composite extractant and the above-mentioned extraction acid are used for countercurrent contact extraction at a ratio of 1:3, and the ratio of the loaded organic phase to the washing water is 20:1 for countercurrent contact washing, and the ratio of the washed organic phase to the distilled water is 25: 1. Carry out countercurrent contact stripping; the composition and weight ratio of the composite extractant are: ketone ether: alcohol: ester=65: 20: 15, the composition and weight ratio of the ketone ether are: ketone: ether =60:40;

[0072] Example 2 Extraction result: extraction rate 87%; Product quality: H 3 PO 4 Content 85.5%, sulfate ≤0.002%, fluorine 0.0007%, iron ≤0.002%, arsenic ≤0.0002%, heavy metal 0.0009%, chloride ≤0.0005%.

Embodiment 3

[0074] Step is with embodiment 1, and difference is:

[0075] Extraction and refining process: the compound extractant and the above-mentioned extraction acid are used for countercurrent contact extraction at a ratio of 1:4, the loaded organic phase and washing water are compared at a ratio of 16:1 for countercurrent contact washing, and the washing organic phase is compared with distilled water at a ratio of 15: 1. Perform countercurrent contact stripping; the composition and weight ratio of the composite extractant are: ketone ether: alcohol: ester = 80: 15: 5, the composition and weight ratio of the ketone ether are: ketone: ether =75:25;

[0076] Example 3 extraction result: extraction rate 90%; product quality: H 3 PO 4 Content 85.5%, sulfate ≤0.002%, fluorine 0.0007%, iron ≤0.002%, arsenic ≤0.0002%, heavy metal 0.0009%, chloride ≤0.0005%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com