Ultrahigh basicity low aluminum fluorine-free refining slag and preparation method and use method thereof

A technology for refining slag and basicity, applied in the field of refining outside the steelmaking furnace, can solve the problems of corrosion of refractory materials, fluorine pollution, easy saturation of the ability to absorb inclusions, etc. Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

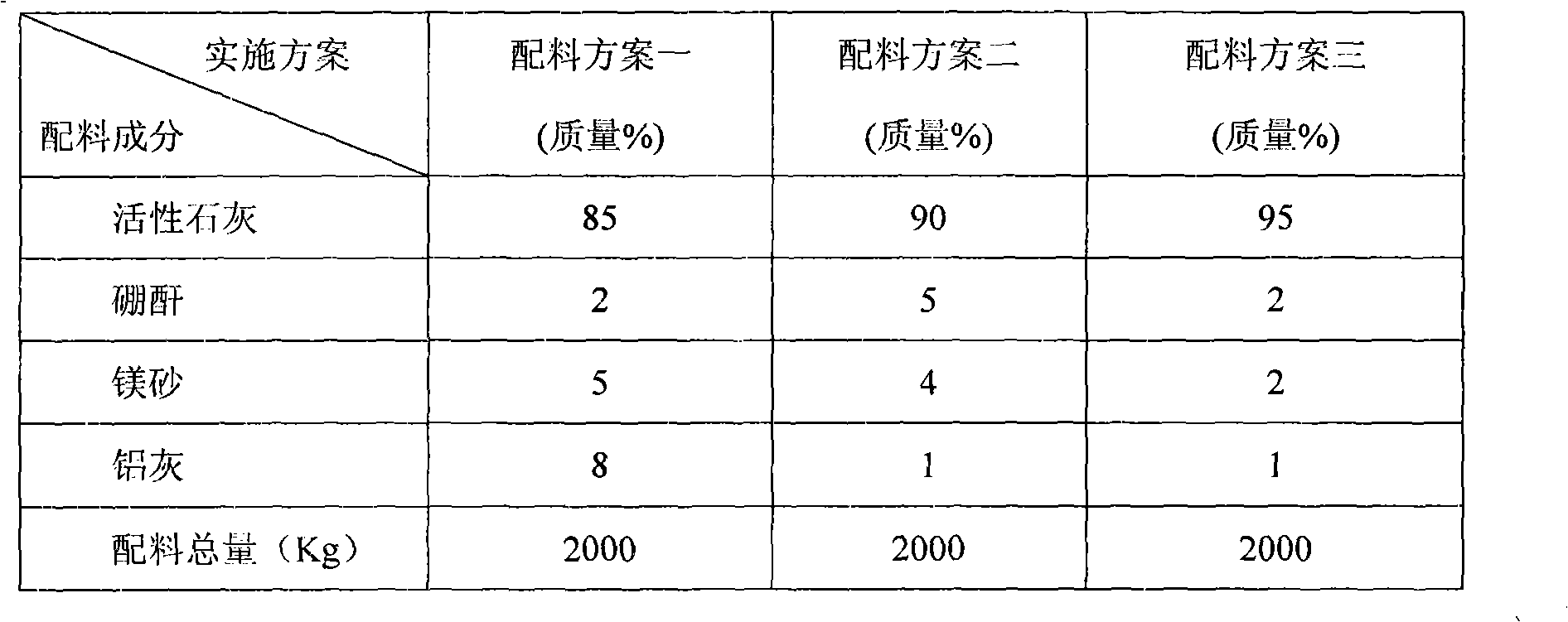

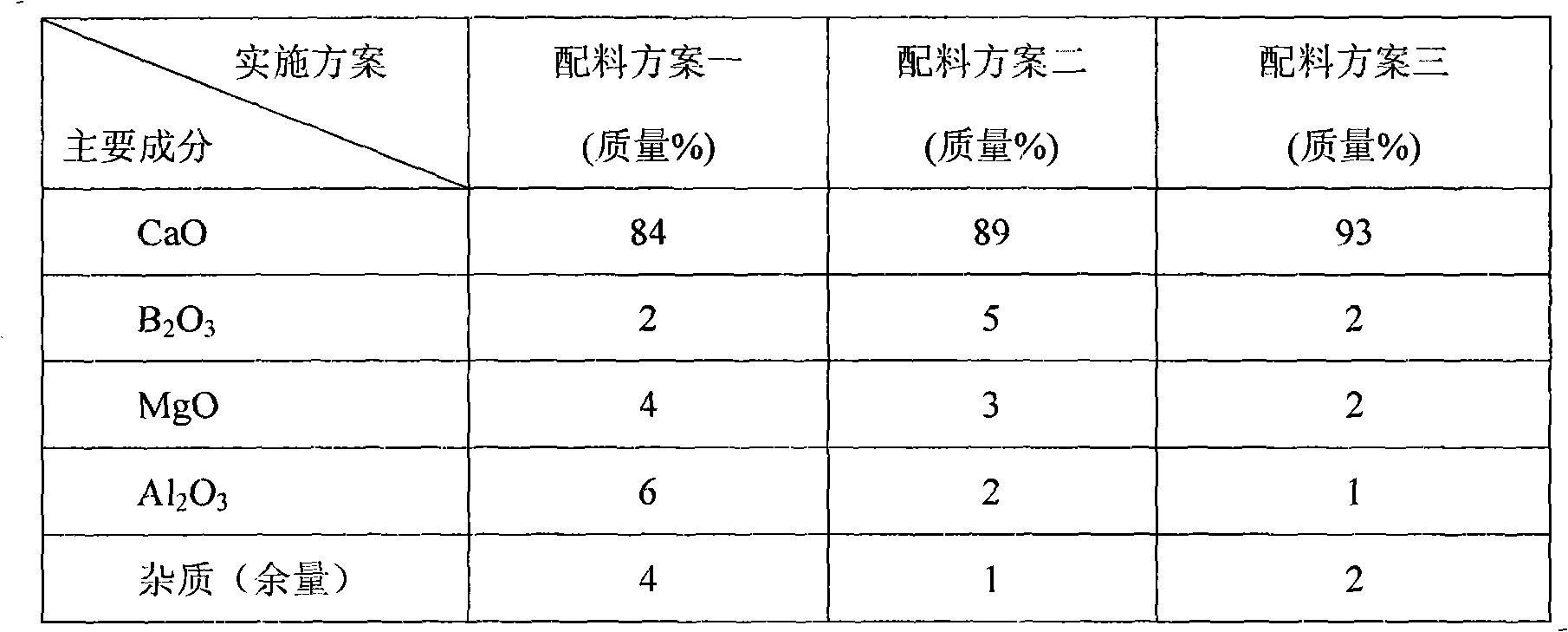

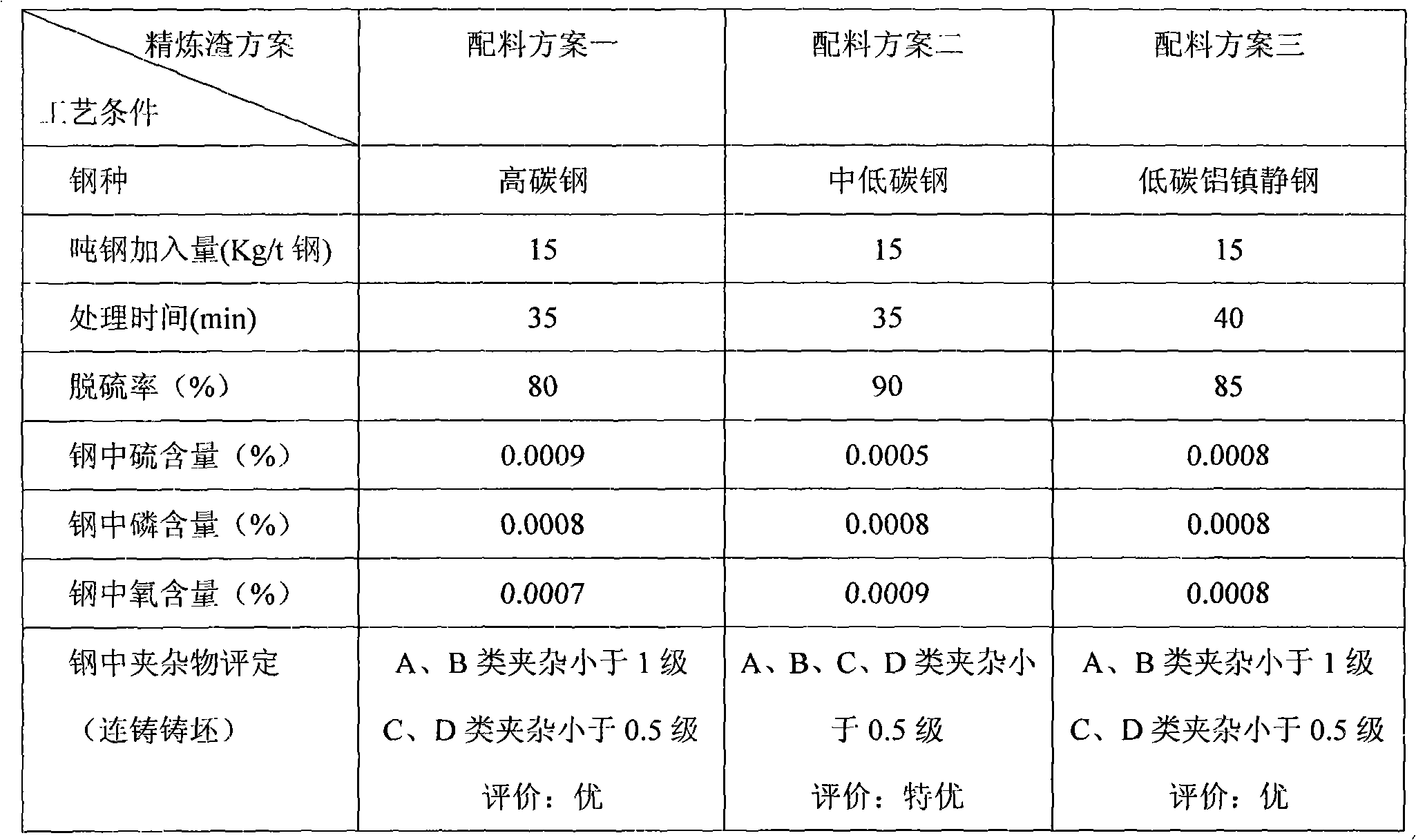

[0029] The present invention will be further elaborated below in conjunction with embodiment. Examples are only used to illustrate the present invention, but not to limit the present invention in any way

[0030] (1) Preparation of premelted refining slag

[0031] The raw materials that embodiment adopts are as follows, and when referring to percentage below, all are percentage by weight:

[0032] The chemical composition of active lime is: 100%>CaO≥90.0, 5%≥MgO>0, 2.5%≥SiO 2 >0, the rest are Al 2 o 3 and other trace impurities;

[0033] Chemical composition of boric anhydride: 100%>B 2 o 3 ≥85.0, 5%≥CaO>0, 3%≥MgO>0, 3%≥SiO 2 >0, the rest are trace impurities;

[0034] The chemical composition of magnesia: 100%>MgO≥90.0, 5%≥CaO>0, 3%≥Al 2 o 3 >0,1%≥SiO 2 >0, the rest are trace impurities;

[0035] Chemical composition of aluminum ash: 100%>Al 2 o 3 ≥90.0, 5%≥CaO>0, 3%≥MgO>0, 1.5%≥SiO 2 >0, the rest are trace impurities;

[0036] Take the above-mentioned raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com