System and method for achieving low-temperature simultaneous desulfurization, denitration and dedusting of flue gas of gas-fired boiler

A gas-fired boiler, desulfurization and denitrification technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of substandard nitrogen oxide emissions, achieve strong desulfurization effect, reduce costs, and solve various environmental protection problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further description will be given below based on specific embodiments.

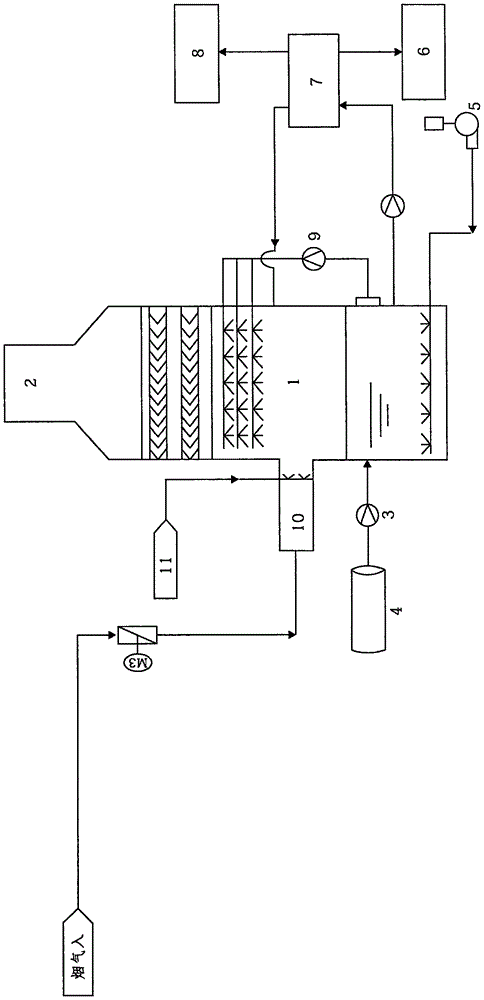

[0031] A system and method for low-temperature synchronous desulfurization, denitrification and dust removal of gas-fired boiler flue gas, the system includes an absorption tower 1, a chimney 2, an ammonia water supply pump 3, an ammonia water supply tank 4, an oxidation fan 5, a slag storage tank 6, and a catalyst separation and recovery system 7 , liquid fertilizer storage tank 8, circulation pump 9, gas distributor 10 and ozone generator 11, after the ozone generator 11 passes through the gas distributor 10, the top of the absorption tower 1 is connected with a straight chimney 2, and the absorption tower 1 The interior is filled with tower internals and a low-temperature organic catalyst. The bottom of the absorption tower 1 is connected to an ammonia water supply pump. There are two ammonia water supply pumps 3, one of which is connected to an ammonia water supply tank 4, and the ammonia water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com