Method for preparing high-performance solid desulfurizing agent by carbide slag slurry

A technology of calcium carbide slurry and desulfurizer, applied in the field of chemical engineering, can solve the problems of occupying large land and polluting the environment, and achieve the effect of strong desulfurization, high activity and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

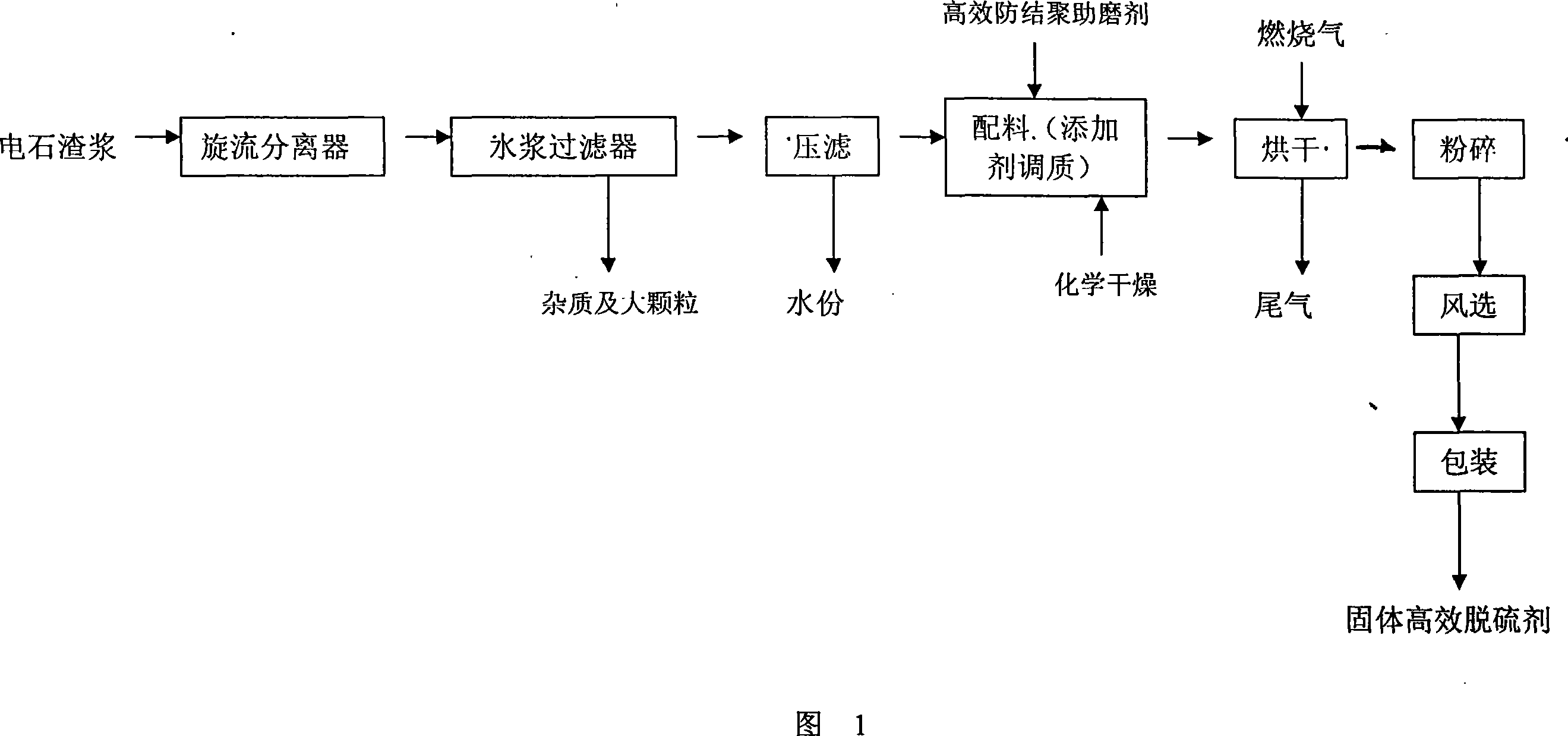

[0011] The calcium carbide slurry discharged from the calcium carbide acetylene production line, 1. Firstly, use a cyclone separator for centrifugal separation, and then filter it with a water slurry filter, so as to separate the ferrosilicon, carbon and large particles of impurities in the calcium carbide slurry from the Slurry is separated. 2. A filter press is used to separate the solids and water in the calcium carbide slurry, and the slurry water is reused in the original production process, and the filter cake enters the next batching process. 3. Use the batching device to fully mix the high-efficiency anti-coagulation grinding aid, chemical desiccant and filter cake, and configure them evenly in proportion. 4. If necessary, use a gas-fired rotary kiln for further calcination and drying. 5. Use milling equipment and winnowing equipment for crushing and winnowing separation, and the separated coarse particles are returned to the crushing process. 6. Use a packaging mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com