Gasoline aromatization and isomerization reforming catalyst and preparation method and applications thereof

A catalyst and aromatization technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of cumbersome catalyst preparation steps and achieve good aromatization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] ①Preparation of catalyst carrier

[0036] 1) Weigh 3.5kg of nanometer ZSM-5 powder, 1.14kg of pseudoboehmite and 120g of scallop powder, mix the three evenly, add 2300ml of nitric acid solution with a mass concentration of 10%, fully knead and place in the extruder forming. Stand at room temperature for 12 hours, then dry at 100°C for 12 hours, and bake at 540°C for 3 hours, and set aside.

[0037] 2) Put 4 kg of the catalyst carrier prepared in the above step 1) in a 0.4 mol / L ammonium nitrate solution at a solid-to-liquid volume ratio of 1:5, and place it at room temperature for 1 hour. After filtering, wash with deionized water until neutral. Repeat the above operation twice. Dry at 100°C for 12h, and bake at 540°C for 3h, and set aside.

[0038] 3) Put 4 kg of the catalyst carrier prepared in the above step 2) in a 0.6 mol / L nitric acid solution at a solid-to-liquid ratio of 1:5, and place it at room temperature for 24 hours. After filtering, wash with deionize...

Embodiment 2

[0044] ① Preparation of catalyst carrier: same as in Example 1.

[0045] ② Preparation of catalyst

[0046] 1) Load 20g of the above-mentioned catalyst carrier A in the constant temperature section of the fixed bed, -1 Introduce steam for 2h.

[0047] 2) Immerse the catalyst treated in the above step 1) in 15ml of a solution containing 3.66g of zinc nitrate and 0.62g of lanthanum nitrate, immerse at room temperature for 24h, filter, dry at 100°C for 12h, and roast at 540°C for 4h to obtain loaded zinc oxide and Lanthanum oxide catalyst.

[0048] 3) Then immerse the catalyst prepared in the above step 2) in 15ml of a solution containing 1.48g of ammonium dihydrogen phosphate, immerse at room temperature for 12h, filter, dry at 100°C for 12h, and roast at 540°C for 4h to obtain the product catalyst E.

Embodiment 3

[0050] ① Preparation of catalyst carrier: same as in Example 1.

[0051] ② Preparation of catalyst

[0052] 1) Load 10g of the above-mentioned catalyst carrier A in the constant temperature section of the fixed bed, -1 Introduce steam for 3h.

[0053] 2) immerse the catalyst after the above step 1) in 8ml of solution containing 0.92g zinc nitrate and 0.27g lanthanum nitrate, soak at room temperature for 24h, filter, dry at 100°C for 12h, and roast at 540°C for 4h to obtain loaded zinc oxide and Lanthanum oxide catalyst.

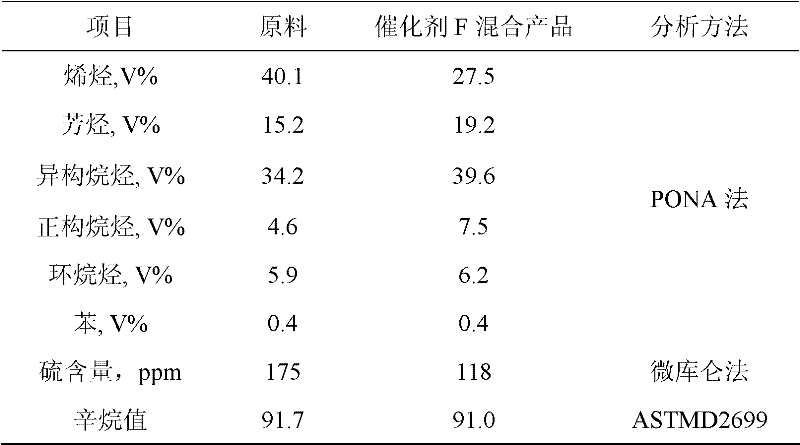

[0054] 3) Immerse the catalyst prepared in the above step 2) in 8ml of a solution containing 0.74g of ammonium dihydrogen phosphate, soak for 24 hours at room temperature, filter, dry at 100°C for 12 hours, and roast at 540°C for 4 hours to obtain the product catalyst F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com