Polyvinyl acetateoxotitaniumprecursor sol spinning solution and preparation method of titanium oxide nano fiber photocatalyst

A technology of sol spinning solution and precursor fibers, which is applied in the directions of physical/chemical process catalysts, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of application performance limitation, difficult removal, slow process, etc., and achieve mechanical properties. Excellent effect of promoting fiber crystallization and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

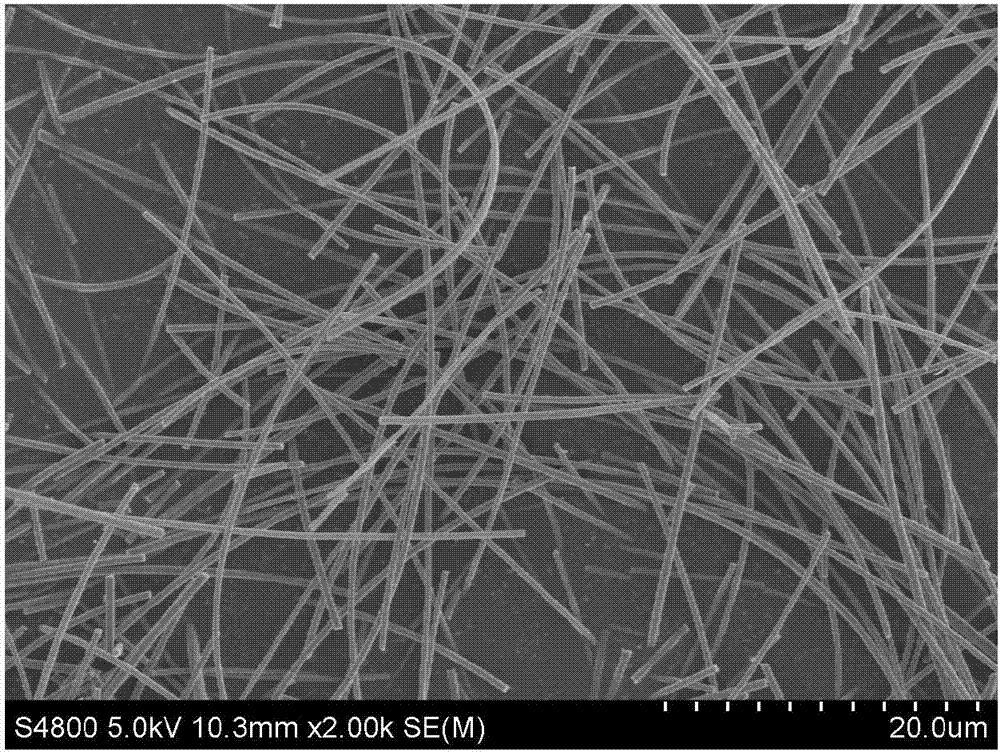

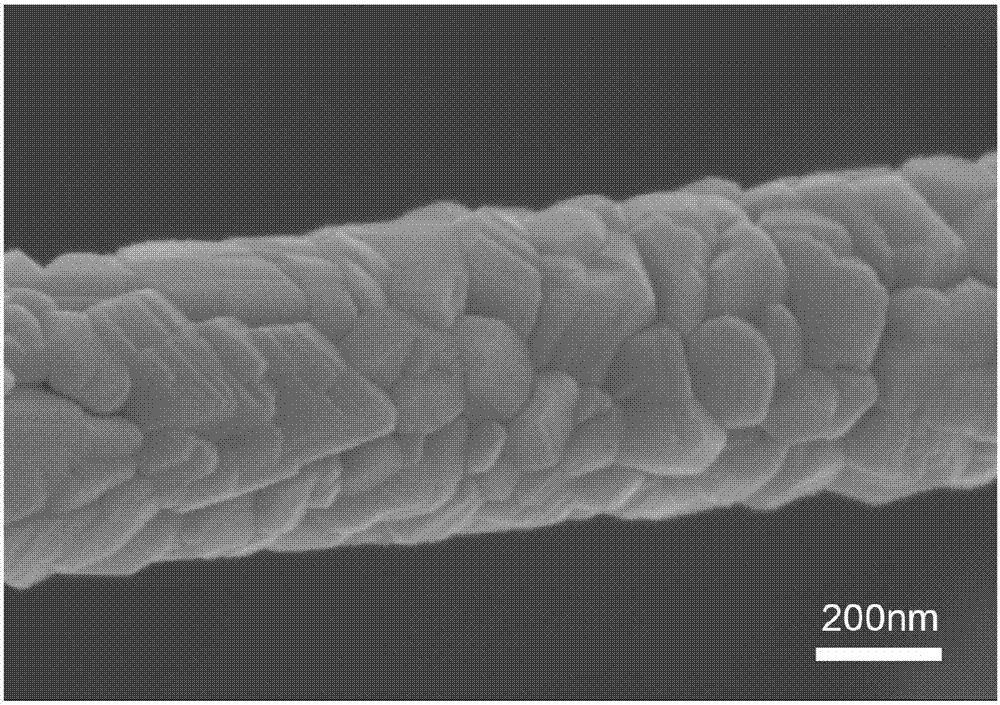

[0057] Embodiment 1: Preparation of titanium oxide nanofibers

[0058] (1) Preparation of poly(titania) acetate precursor

[0059] Weigh 100g of tetrabutyl titanate and 52.94g of glacial acetic acid, fully stir and react for 3 hours to obtain a golden yellow solution, that is, poly-titanyl acetate solution; place it in a flask, and concentrate under reduced pressure at a temperature of 65°C for 6 hours until obtaining The dry solid, namely the poly(titalyl acetate) precursor; the stability test of the obtained precursor: the sol formed by dissolving the just prepared poly(titalyl acetate) precursor powder in anhydrous methanol solvent can be placed continuously for more than 6 weeks, Still clear and transparent. The obtained precursor powder was placed for 4 weeks and then dissolved in anhydrous methanol solvent to form a sol, which could be placed continuously for more than 6 weeks and remained clear and transparent. It shows that the stability of the precursor is very good...

Embodiment 2

[0074] As described in Example 1, the difference is that 100g tetrabutyl titanate and 23.49g glacial acetic acid are weighed in step (1), fully stirred and reacted for 3h to obtain a golden yellow solution, i.e. poly-titanyl acetate solution; Concentrate under reduced pressure in a flask for 9 hours at a temperature of 65° C. to obtain a dry light yellow solid, which is the precursor of poly(titanate) titanyl acetate. The sol formed by dissolving the obtained precursor powder in an alcoholic solvent can be placed stably for 5 weeks.

Embodiment 3

[0076] As described in Example 1, the difference is that step (1) weighs 100g tetrabutyl titanate and 70.5g glacial acetic acid, fully stirs and reacts for 3 hours, and obtains a golden yellow solution, that is, polyoxytitanyl acetate solution; Place in a flask, concentrate under reduced pressure at a temperature of 65° C., and obtain a dry light yellow solid, which is a poly(titanate) acetate precursor. After the obtained precursor powder is placed for 4 weeks, the sol formed by dissolving it in an alcoholic solvent can be placed stably for 3 weeks, and precipitation will gradually begin to form after more than 3 weeks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com