Preparation method of micron/submicron order silver powder

A sub-micron silver powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low sintering activity of silver powder, high sintering activity of silver powder, poor dispersion, etc., achieve good dispersion, easy to remove, and prevent agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

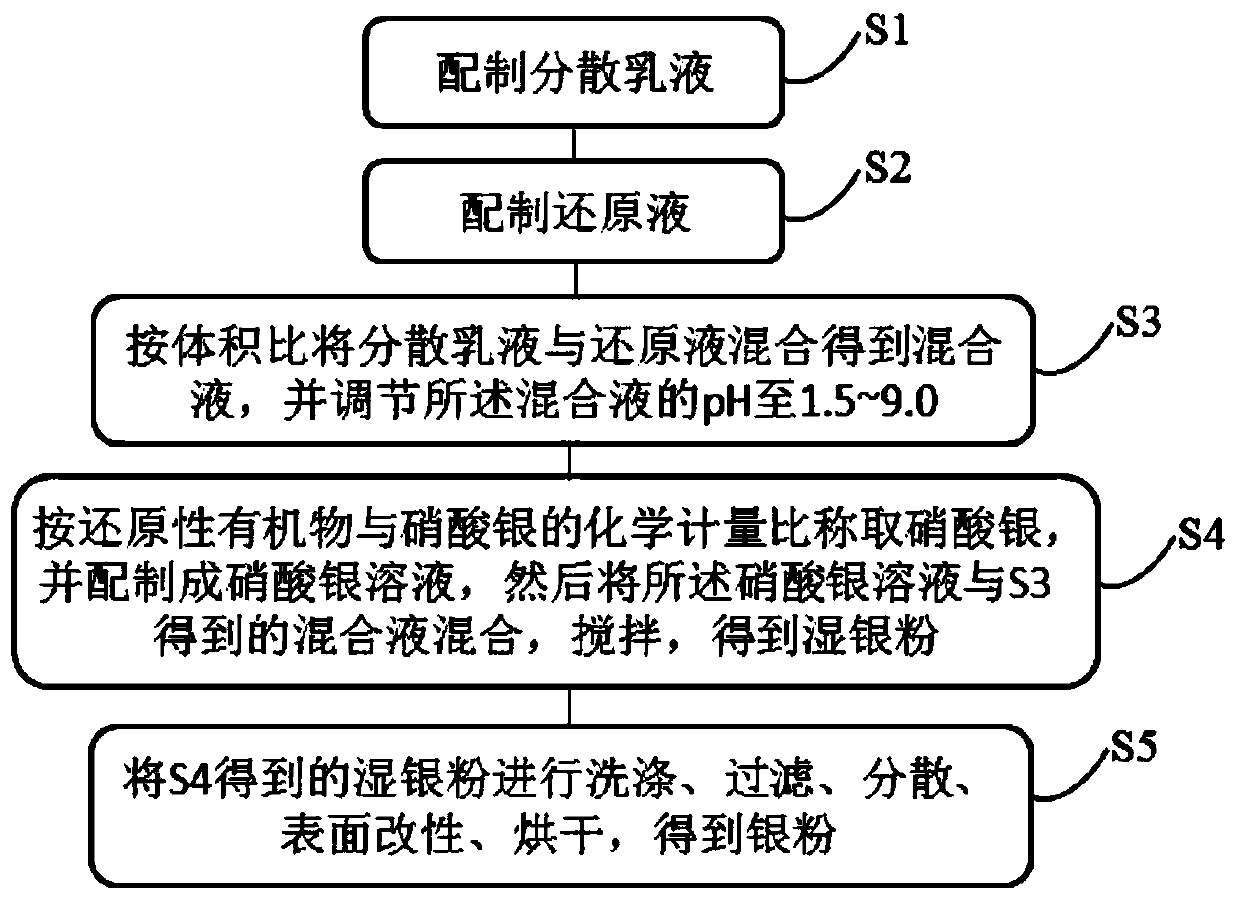

[0021] The present invention proposes a kind of preparation method of micron / submicron silver powder, comprising:

[0022] S1: preparing a dispersion emulsion, the dispersion emulsion includes a dispersant, an emulsifier and a solvent;

[0023] The dispersion emulsion is used to increase the dispersibility of the prepared silver powder.

[0024] In the preparation method provided by the invention, the dispersant is formulated into a dispersed emulsion first, in order to make the dispersant difficult to attach to the surface of the newly generated silver powder, so that the redundant dispersant can be easily removed when the silver powder is washed, so that the prepared silver powder Has a lower weight loss on ignition.

[0025] Preferably, the specific preparation process of the dispersed emulsion is:

[0026] S11: Weigh the dispersant, emulsifier and solvent according to the mass ratio (3~10):(30~80):(15~60);

[0027] S12: Stir the dispersant, emulsifier and solvent weighe...

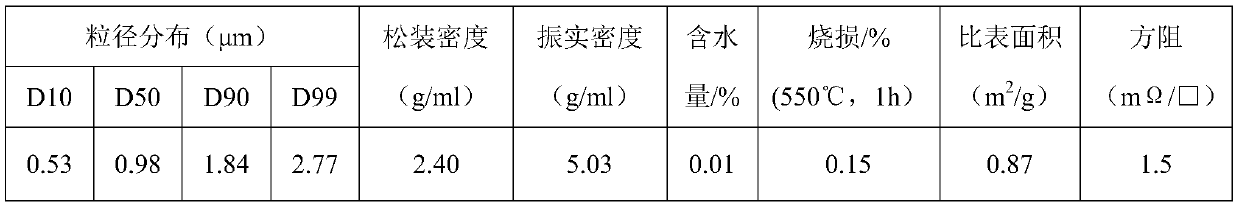

Embodiment 1

[0050] The present embodiment provides a kind of preparation method of micron / submicron silver powder, comprising:

[0051] S1: To prepare a dispersed emulsion, accurately weigh oleic acid, Tween 80 and ethanol according to the mass ratio of 6:60:34, stir evenly at 35°C, and add deionized water while stirring (the amount of deionized water added is oil acid, Tween 80 and 200% of the total mass of ethanol) to obtain a pale blue dispersed emulsion;

[0052] S2: preparing a reducing solution, weighing vitamin C and deionized water according to a mass ratio of 5:95 (the concentration of reducing organic matter in the reducing solution is 5%), and mixing uniformly at a constant temperature of 25°C to obtain a reducing solution;

[0053] S3: Mix the dispersed emulsion and the reducing solution at a volume ratio of 1:10 to obtain a mixed solution, and adjust the pH value of the mixed solution to 4.5±0.1 with ammonia water;

[0054] S4: Weigh silver nitrate according to the stoichiom...

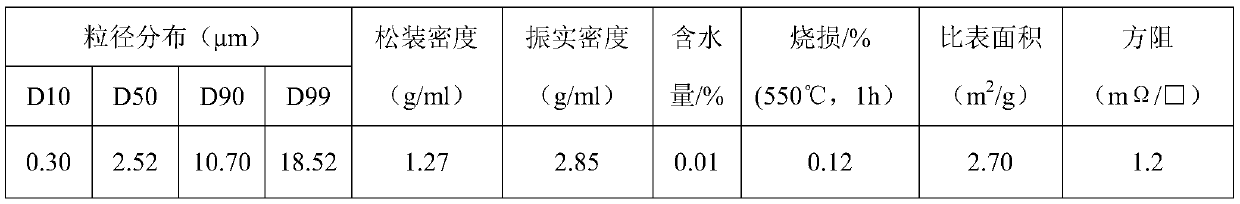

Embodiment 2

[0061] The present embodiment provides a kind of preparation method of micron / submicron silver powder, comprising:

[0062] S1: To prepare a dispersed emulsion, accurately weigh stearic acid, Tween 60 and methanol according to the mass ratio of 3:30:67, stir evenly at 25°C, and add deionized water while stirring (the amount of deionized water added is 100% of the total mass of stearic acid, Tween 60 and methanol), to obtain a pale blue dispersed emulsion;

[0063] S2: preparing a reducing solution, weighing glucose and deionized water according to a mass ratio of 1:99 (the concentration of reducing organic matter in the reducing solution is 1%), and mixing uniformly at a constant temperature of 45° C. to obtain a reducing solution;

[0064] S3: Mix the dispersed emulsion and the reducing solution at a volume ratio of 1:2 to obtain a mixed solution, and adjust the pH value of the mixed solution to 9.0±0.1 with ammonia water;

[0065] S4: Weigh silver nitrate according to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com