Modified active carbon, and preparation method and application thereof

A technology of activated carbon and modification, which is applied in chemical instruments and methods, preparation/separation of ammonia, inorganic chemistry, etc. It can solve the problems that the stability needs to be further improved, and achieve the improvement of anti-methanation ability, high mesopority, and pore size. distribution concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

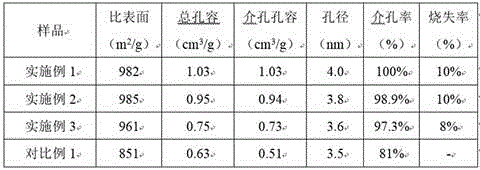

Embodiment 1

[0020] A preparation method of modified activated carbon, the concrete steps are:

[0021] (1) Pretreatment of activated carbon: 5 g of commercial activated carbon was graphitized at 1900 °C for 10 hours in an argon inert atmosphere, and then subjected to pore expansion treatment at 450 °C for 30 hours in an oxygen atmosphere to obtain pretreated activated carbon, washed, dry and ready for use;

[0022] (2) Modification of graphitized activated carbon: The activated carbon pretreated in step (1) was crushed and screened to obtain 12-16 mesh activated carbon particles, soaked in a nitric acid solution with a concentration of 5 wt% at 70 °C, and kept at a constant temperature for 2 h, take it out, wash it with distilled water until neutral, and dry it in an oven at 110 °C for 12 h; then place the dried sample in an ammonia atmosphere at 1100 °C for heat treatment for 2 h, with a gas flow rate of 75ml / min, and drop it to room temperature in the atmosphere Take it out to get the ...

Embodiment 2

[0024] A preparation method of modified activated carbon, the concrete steps are:

[0025] (1) Pretreatment of activated carbon: 5 g of commercial activated carbon was graphitized at 2000 °C for 2 hours in an inert argon atmosphere, and then subjected to pore expansion treatment at 450 °C for 30 hours in an oxygen atmosphere to obtain pretreated activated carbon, washed, dry and ready for use;

[0026] (2) Modification of graphitized activated carbon: The activated carbon pretreated in step (1) was crushed and screened to obtain 12-16 mesh activated carbon particles, soaked in a nitric acid solution with a concentration of 10 wt% at 60 °C, and kept at a constant temperature for 3 h, take it out, wash it with distilled water until neutral, and dry it in an oven at 90 °C for 16 h; then place the dried sample in an ammonia atmosphere at 1100 °C for 2 h, with a gas flow rate of 100 ml / min, and take it out when the atmosphere drops to room temperature , the modified activated carb...

Embodiment 3

[0028] A preparation method of modified activated carbon, the concrete steps are:

[0029] (1) 5 g of commercial activated carbon was graphitized at 1800 °C for 5 hours in an argon inert atmosphere, and then subjected to pore expansion treatment at 460 °C for 20 hours in an oxygen atmosphere to obtain pretreated activated carbon, which was washed and dried for later use;

[0030] (2) Modification of graphitized activated carbon: The activated carbon pretreated in step (1) was crushed and screened to obtain 12-16 mesh activated carbon particles, soaked in a nitric acid solution with a concentration of 7 wt% at 75 °C, and kept at a constant temperature for 1 h, take it out, wash it with distilled water until neutral, and dry it in an oven at 100 °C for 14 h; then place the dried sample in an ammonia atmosphere at 900 °C for heat treatment for 2 h, with a gas flow rate of 50ml / min, and drop it to room temperature in the atmosphere Take it out to get the modified activated carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com