Automatic control system for active carbon processing preparaing procedure

A technology of automatic control system and preparation process, applied in the field of activated carbon processing, can solve the problems affecting the economic benefits of enterprises, unstable product quality, low product yield, etc., and achieve the effects of reasonable design, improved labor efficiency, and increased activation yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

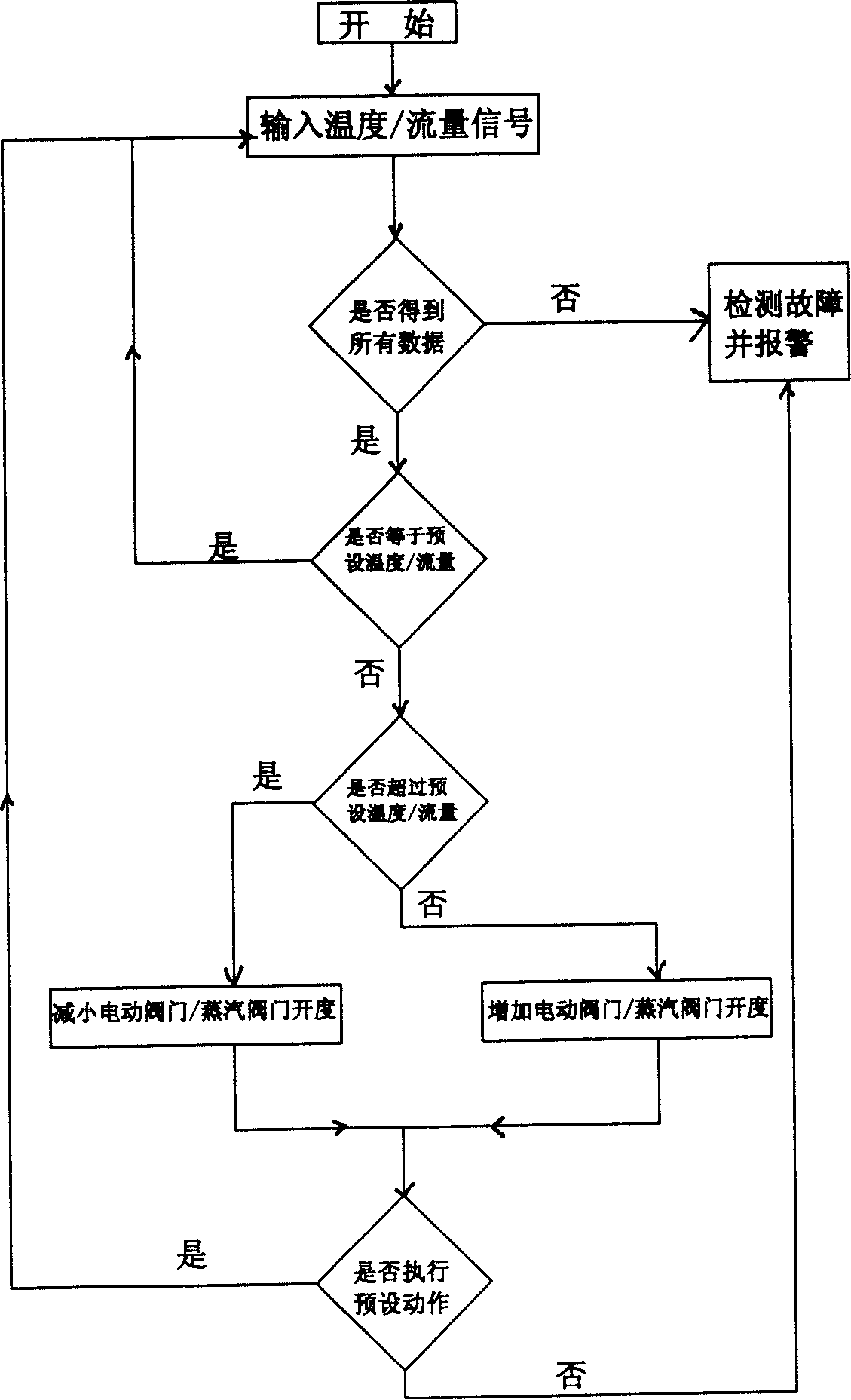

Method used

Image

Examples

Embodiment Construction

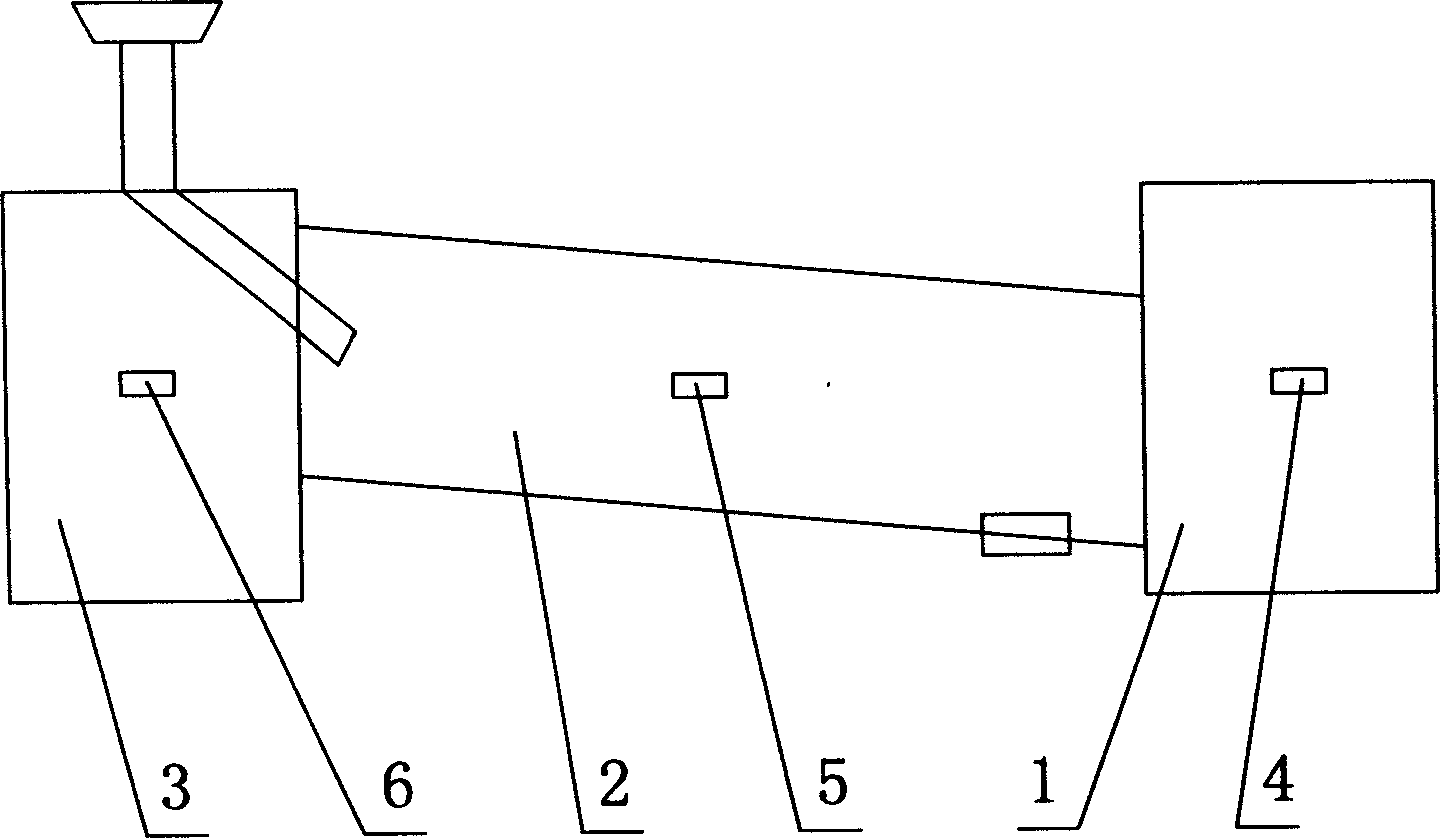

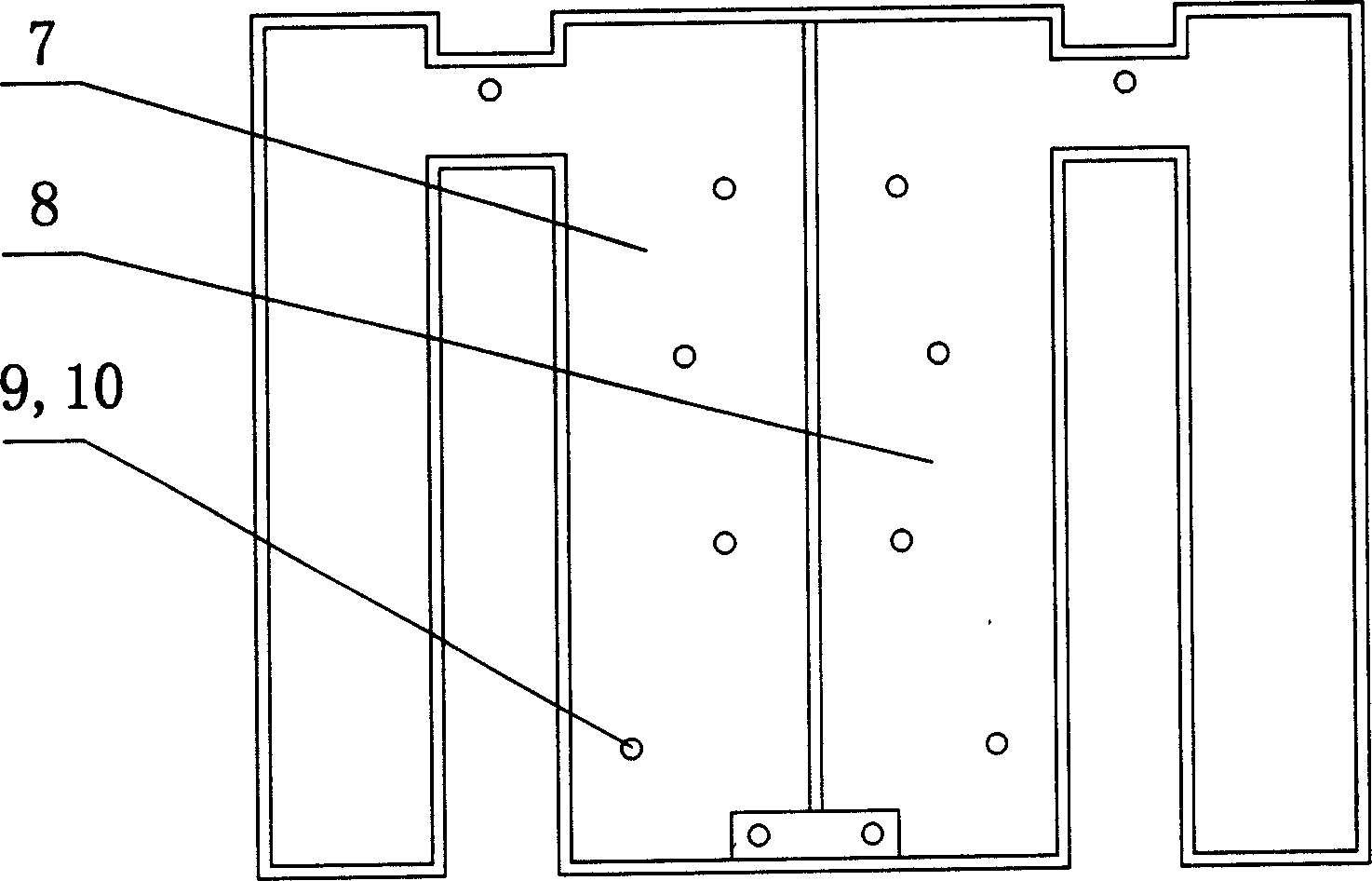

[0016] To further explain the present invention:

[0017] In the known technology, the computer is the most important part of the automation control. It includes a CPU, a memory, and multiple input / output ports. The memory stores instructions and data. The instructions are the part that guides the CPU action code prepared by the user. The data is made by the CPU. The processed information encoding part, a set of logical instructions stored in the memory is called a program. Therefore the CPU "reads" each instruction in a logical sequence from the memory and uses it to initiate processing operations. In actual work, the CPU can quickly access any data stored in the memory, but the data that often needs to be processed is not known in advance or cannot be obtained from the existing information. This problem is solved by configuring a computer with one or more input / output ports, and then the CPU addresses these ports and inputs data from the external device coupled with it or inputs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com