Production line for regenerating wood based powdered activated carbon

A powdered activated carbon and production line technology, which is applied in filter regeneration, filtration separation, petroleum industry, etc., can solve the problems of inability to form large-scale and automatic control production, poor regeneration quality, and high regeneration cost, and achieve large-scale and automation The effect of controlled production, low loss on ignition rate, and low regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

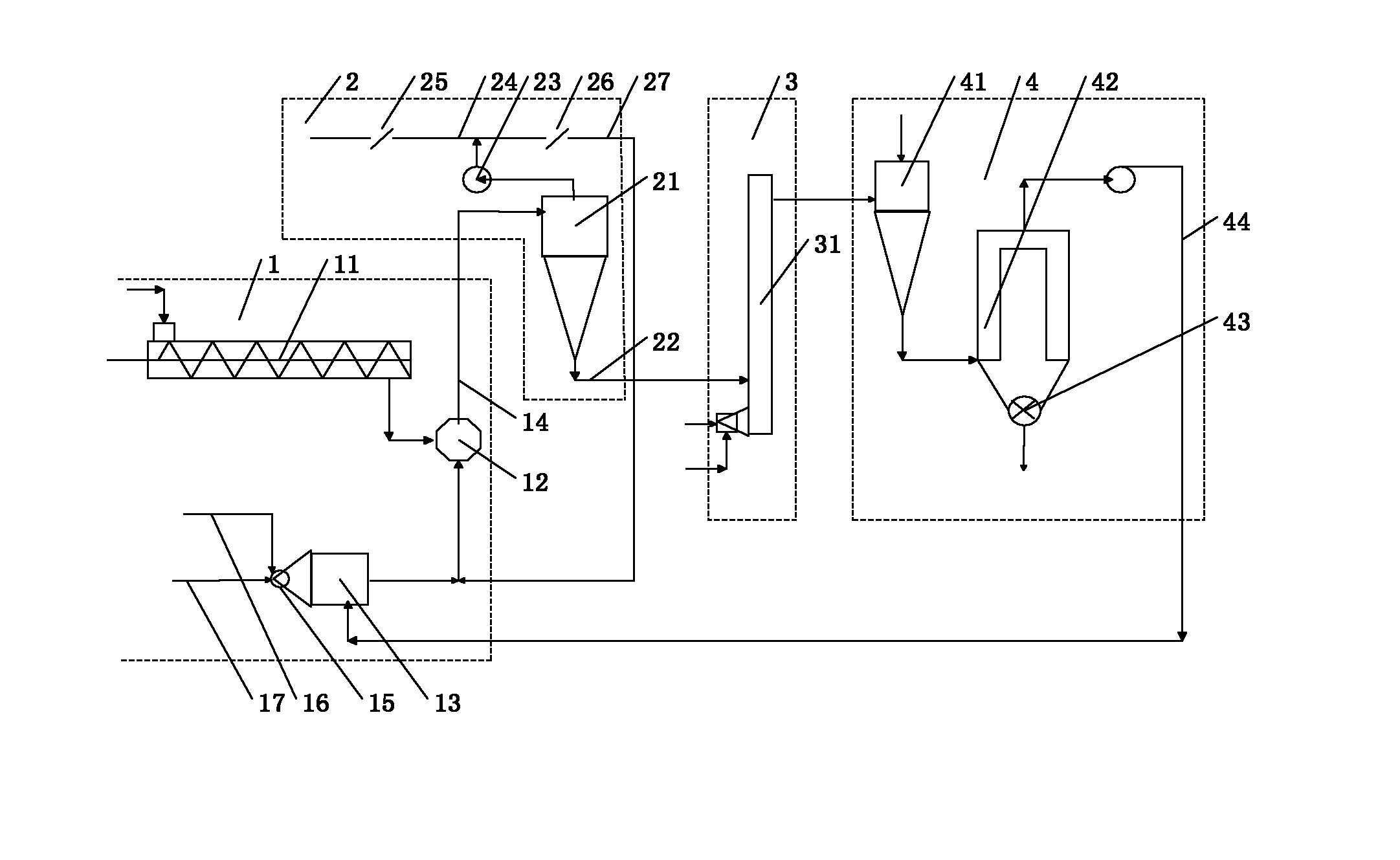

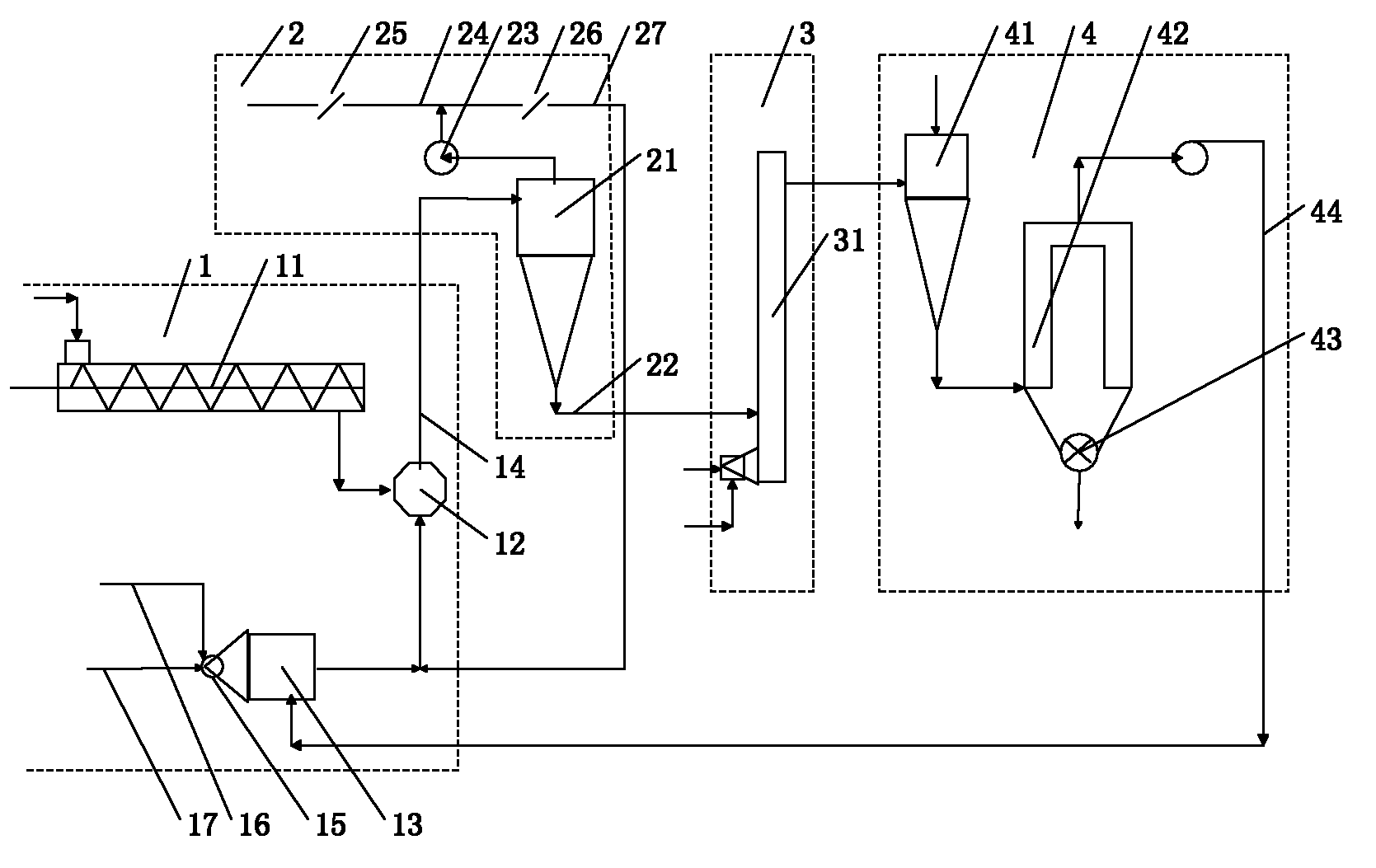

[0013] Wooden powdery activated carbon regeneration production line, including crushing and drying equipment 1, cyclone separation equipment 2, high-temperature vertical kiln activation furnace 3, cooling bag filter equipment 4, peat is dehydrated by plates and frames and enters the crushing and drying equipment 1 of this production line, crushing and drying equipment 1 The output end of the cyclone separation device 2 is connected to the cyclone separation device 2 through the drying pipe, the output end of the cyclone separation device 2 is connected to the high-temperature vertical kiln activation furnace 3 through a pipeline, and the high-temperature vertical kiln activation furnace 3 is connected to the cooling bag filter device 4 through a pipeline.

[0014] The peat is dehydrated through the plate and frame and enters the crushing and drying equipment. The peat with a moisture content of 70% is dried at a high temperature, and the moisture content is reduced to about 20%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com