Equalizing charge circuit and battery pack

A technology of balanced charging and battery packs, applied in battery circuit devices, circuit devices, current collectors, etc., can solve the problems of global impact, high system requirements, and large energy loss, achieving small global impact, low system requirements, and energy loss. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

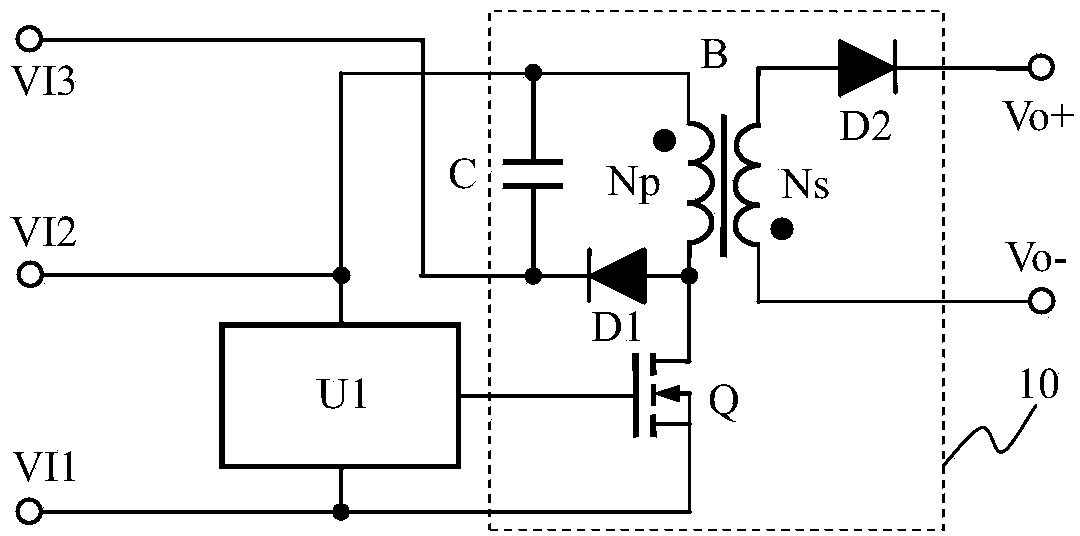

[0039] see image 3 , is a balanced charging circuit, used in parallel with a single battery in the series battery pack, including the first input terminal VI1, the second input terminal VI2, the third input terminal VI3, the output positive terminal Vo+, and the output negative terminal Vo -, the detection circuit U1 and the flyback DC-DC converter 10 controlled by the detection circuit U1, the flyback DC-DC converter 10 includes an N-MOS transistor Q (N-MOS is an N-channel metal oxide semiconductor field effect tube), transformer B, first diode D1, second diode D2, capacitor C; the detection circuit U1 is connected in parallel between the first input terminal VI1 and the second input terminal VI2, and the output terminal of the detection circuit It is connected to the gate of the N-MOS transistor Q, the source of the N-MOS transistor Q is connected to the first input terminal VI1, and the drain of the N-MOS transistor Q is connected to the primary winding N of the transforme...

no. 2 example

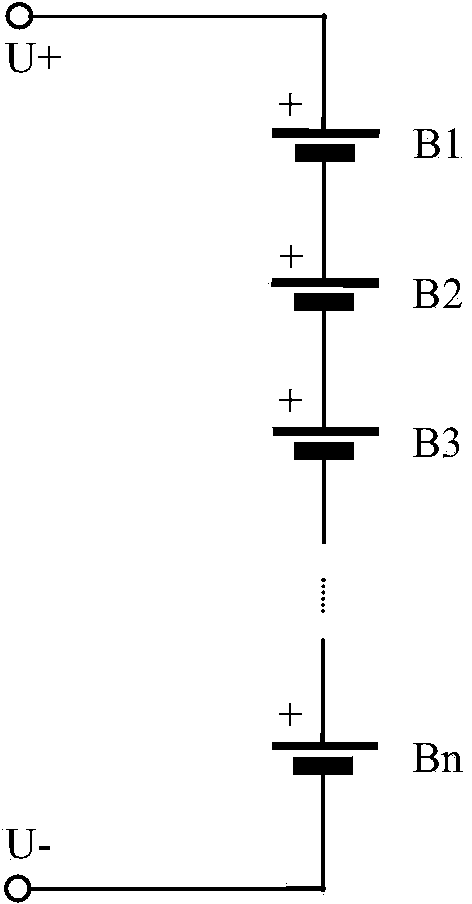

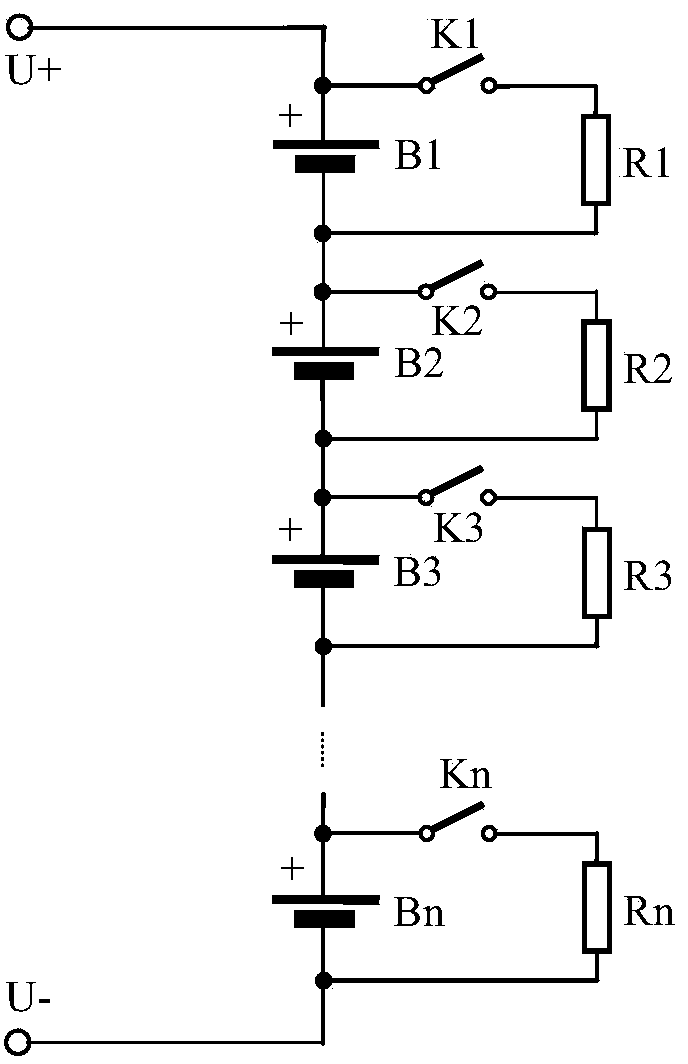

[0054] Therefore, the present invention also provides a battery pack using a plurality of equalizing charging circuits, each single battery in the battery pack uses a corresponding equalizing charging circuit, and the output positive terminals of all equalizing charging circuits are connected together and connected to the battery On the positive pole of the battery pack, the output negative terminals are connected together and connected to the negative pole of the battery pack. Among them, the single battery closest to the positive pole of the battery pack is called the first single battery, and the serial numbers of the other single batteries are deduced by analogy. Features are:

[0055] The first equalizing charging circuit (hereinafter referred to as the first circuit) applied to both ends of the first single battery in the battery pack, the first input terminal of the first circuit is connected to the negative pole of the first single battery, the second of the first circu...

no. 3 example

[0061] Equalizing charging circuit using P-MOS tube, see Figure 4 , Figure 5 shows and Figure 4 The schematic diagram of the connection relationship is exactly the same, in order to facilitate the understanding of the equalization charging circuit using the P-MOS tube applied to the first single battery.

[0062] The connection relationship is that a balanced charging circuit using P-MOS transistors includes a first input terminal VI1, a second input terminal VI2, a third input terminal VI3, an output positive terminal Vo+, an output negative terminal Vo-, and a detection circuit U1 And the flyback DC-DC converter 10 controlled by the detection circuit U1, the output positive terminal Vo+ is connected to the positive pole of the battery pack, and the output negative terminal Vo- is connected to the negative pole of the battery pack; the flyback DC-DC The converter 10 includes a P-MOS transistor Q, a transformer B, a first diode D1, a second diode D2, and a capacitor C; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com