Generating set optimization control method for correcting sliding pressure operation curve by adopting steam consumption rate

A generator set and optimization method technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the mismatch between the intake steam volume and the main steam pressure, the large change in the steam consumption rate of the unit, and reduce the unit Economical and other issues, to achieve the effect of small throttling loss, low throttling loss, and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

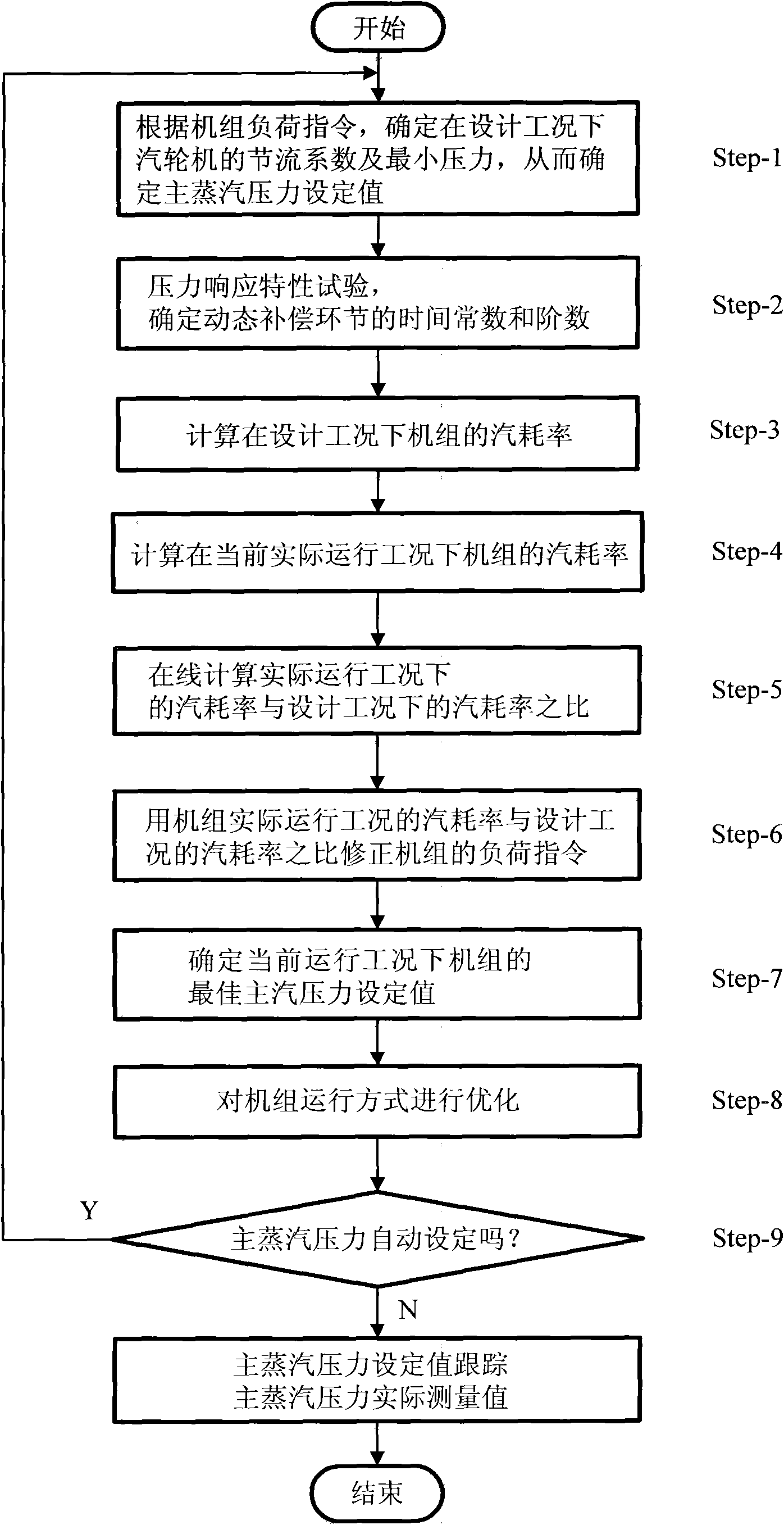

[0024] The specific implementation process of the present invention will be further described in detail below in conjunction with the accompanying drawings.

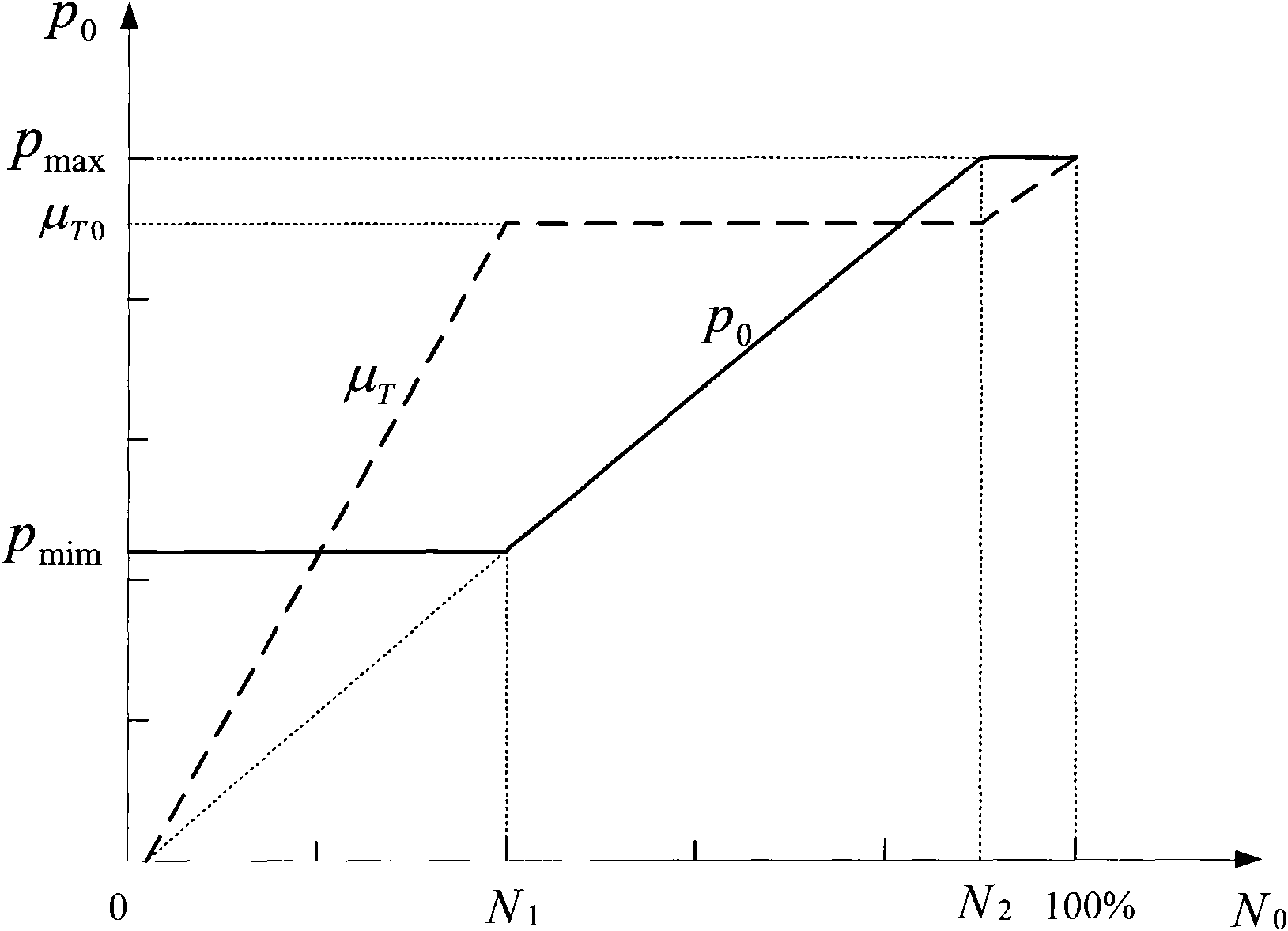

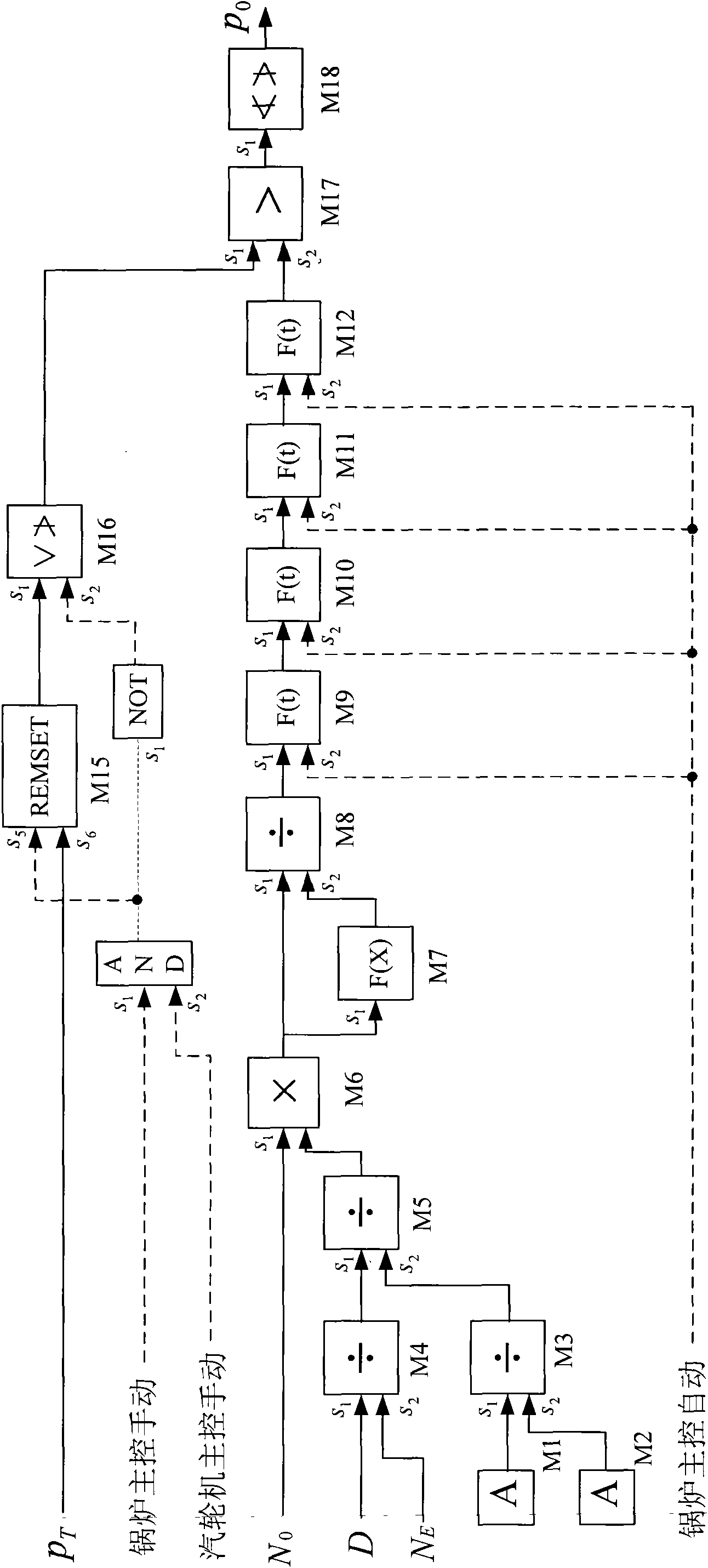

[0025] First, according to the unit load command N 0 And the throttling coefficient and minimum pressure of the steam turbine under the design working condition, determine the set value of the main steam pressure. figure 1 The curve shown is the design condition, the throttling coefficient is 10%, and the minimum pressure is P min The main steam pressure set point curve; when using DCS control system configuration, such as image 3 As shown, the setting of the throttling coefficient of the steam turbine is realized through the function module F(x)(M7); the minimum pressure setting value of the steam turbine can be set through the REMSET module (M15) of the remote setting station; Form the comprehensive sliding pressure operation curve of the generating set;

[0026] In the second step, after the actual pressure dynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com