Patents

Literature

38results about How to "Suitable for long cycle operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

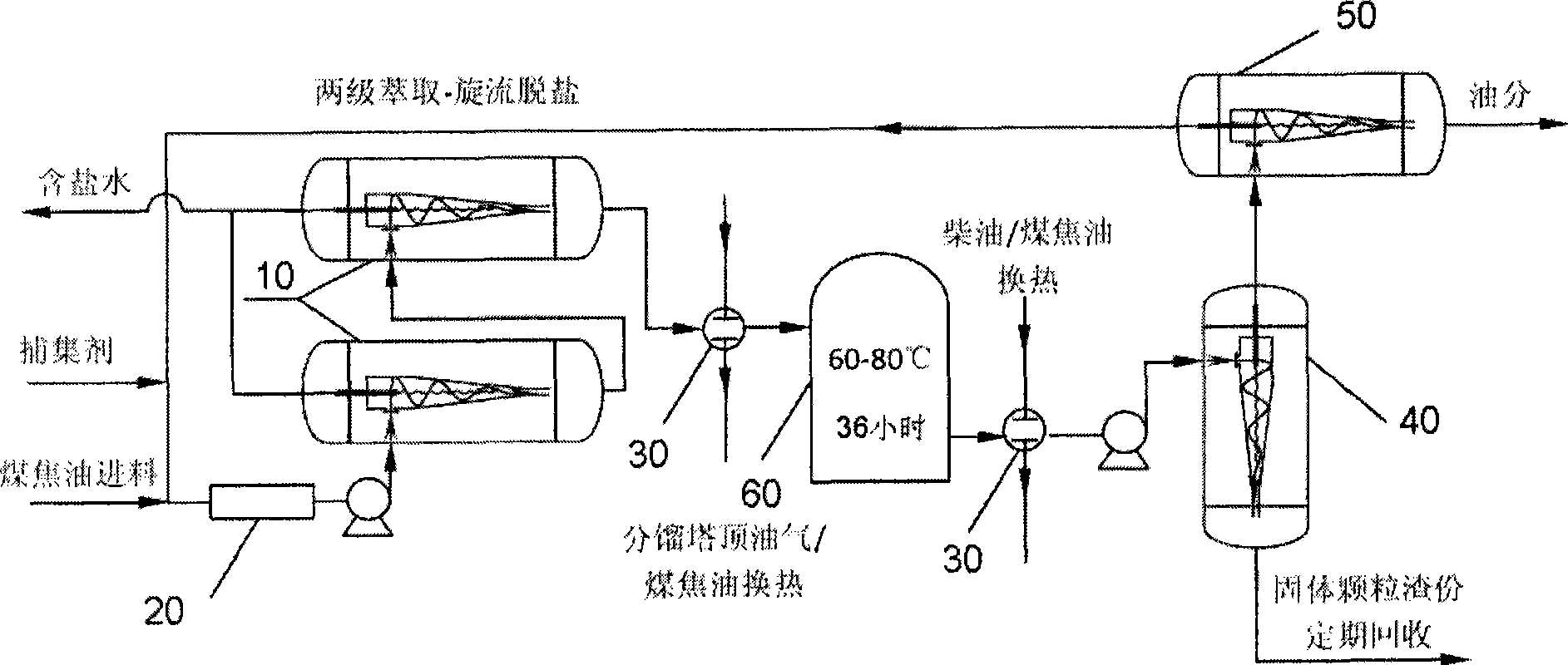

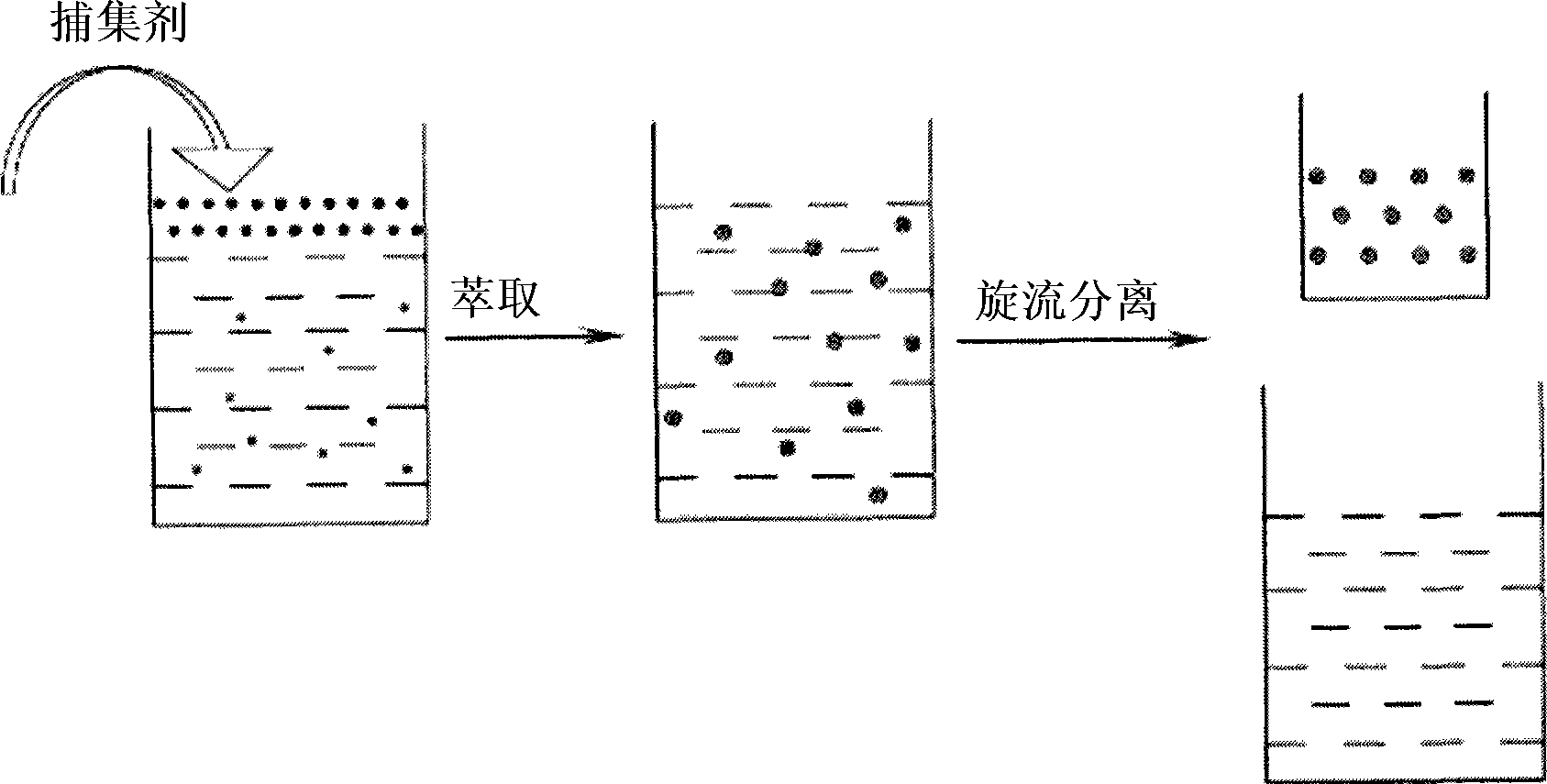

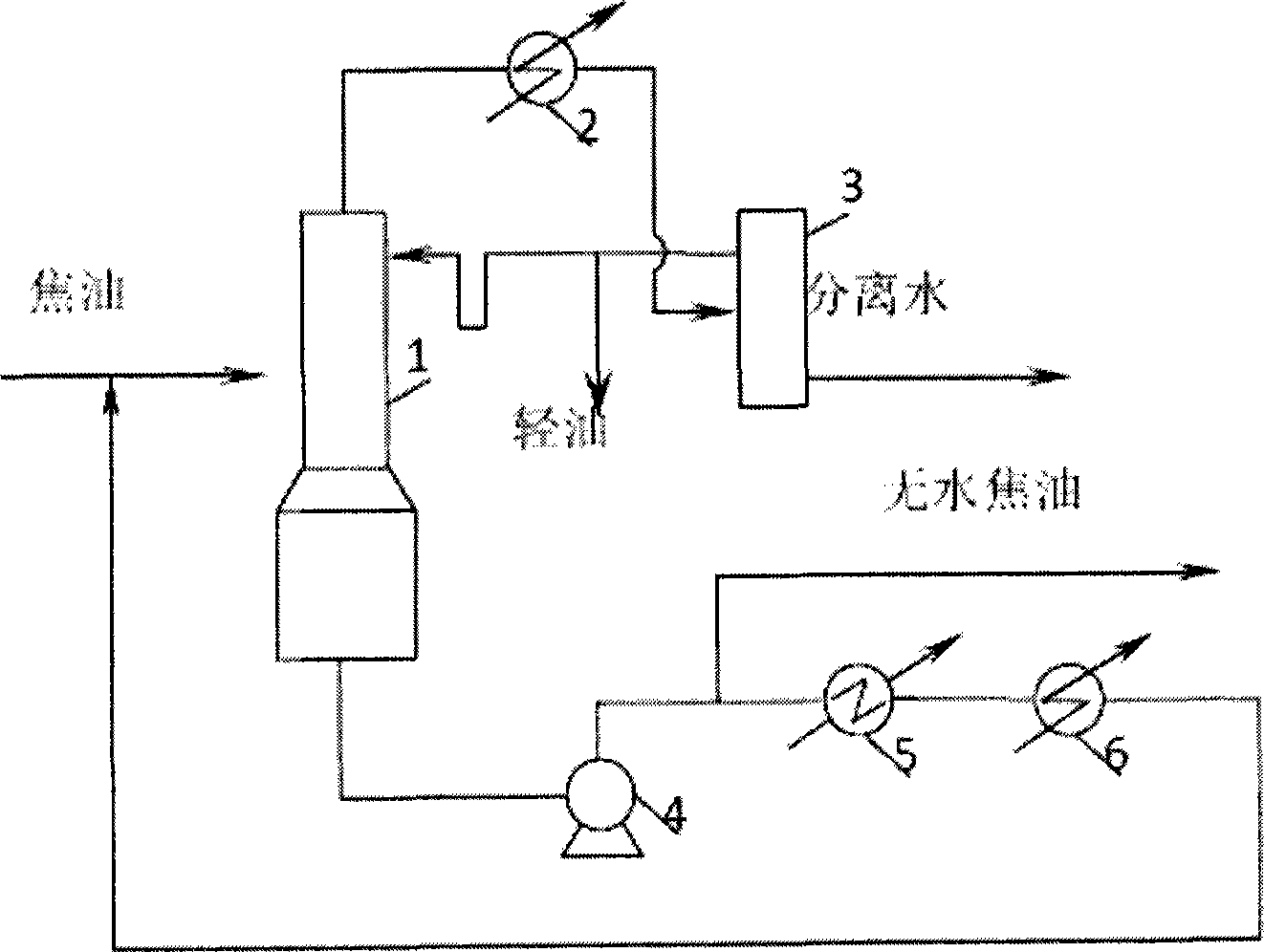

Coal tar coupled rotational flow purification method and apparatus

ActiveCN101475818AReduce heat consumptionReduce resistanceTar working-up by water removalTar working-up by solvent extractionPurification methodsPhysical chemistry

The invention relates to a method and a device for purifying coal tar through coupling rotational flow, wherein the method for purifying the coal tar through coupling rotational flow comprises the following steps: (a) mixing coal tar feed with a trapping agent sufficiently so as to extract out saline matters dispersed in the coal tar; (b) performing liquid-liquid rotational flow separation on thecoal tar in which the dispersed saline matters are extracted out for separating out the saline matters so as to obtain desalinated coal tar; (c) keeping stand and depositing the desalinated coal tar so as to remove the moisture therein and obtain dehydrated coal tar; (d) performing solid-liquid rotational flow separation on the dehydrated coal tar so as to remove solid particles therein and obtain the coal tar without the solid particles; and (e) performing micro rotational flow separation on the coal tar without the solid particles so as to remove the micro moisture therein. The invention also provides a device for purifying the coal tar through the coupling rotational flow.

Owner:EAST CHINA UNIV OF SCI & TECH

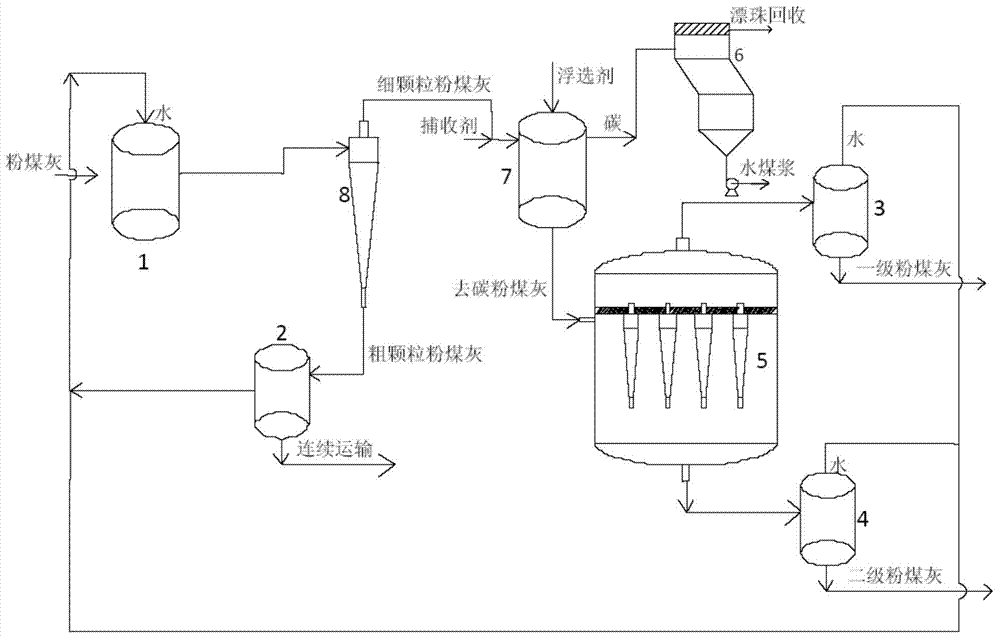

High-carbon pulverized coal ash/coal slag decarbonization and classification method and device

The invention relates to a high-carbon pulverized coal ash / coal slag decarbonization and classification method and device and provides a high-carbon pulverized coal ash / coal slag decarbonization and classification method. The method comprises the following steps of 1 mixing coal ash / coal slag with water, utilizing solid-liquid rotational flows to remove large particles in coal slag and obtain coal ash / coal slag subjected to pre-deslagging treatment; 2 adding a collector agent into the coal ash / coal slag subjected to pre-deslagging treatment, performing ore pulp pretreatment, performing even stirring, feeding the mixture into a flotation column for flotation, recovering floating carbon powder, and discharging out the coal ash / coal slag; 3 performing classified whirling on the coal ash / coal slag deposited in the flotation column, collecting first-grade pulverized coal ash, discharging out second-grade pulverized coal ash and third-grade pulverized coal ash; 4 performing dehydration treatment on the large particles obtained in the step 1, the carbon powder obtained in the step 2 and the pulverized coal ash obtained in the step 3 and recovering water for recycle. The invention further provides a high-carbon pulverized coal ash / coal slag decarbonization and classification device.

Owner:EAST CHINA UNIV OF SCI & TECH

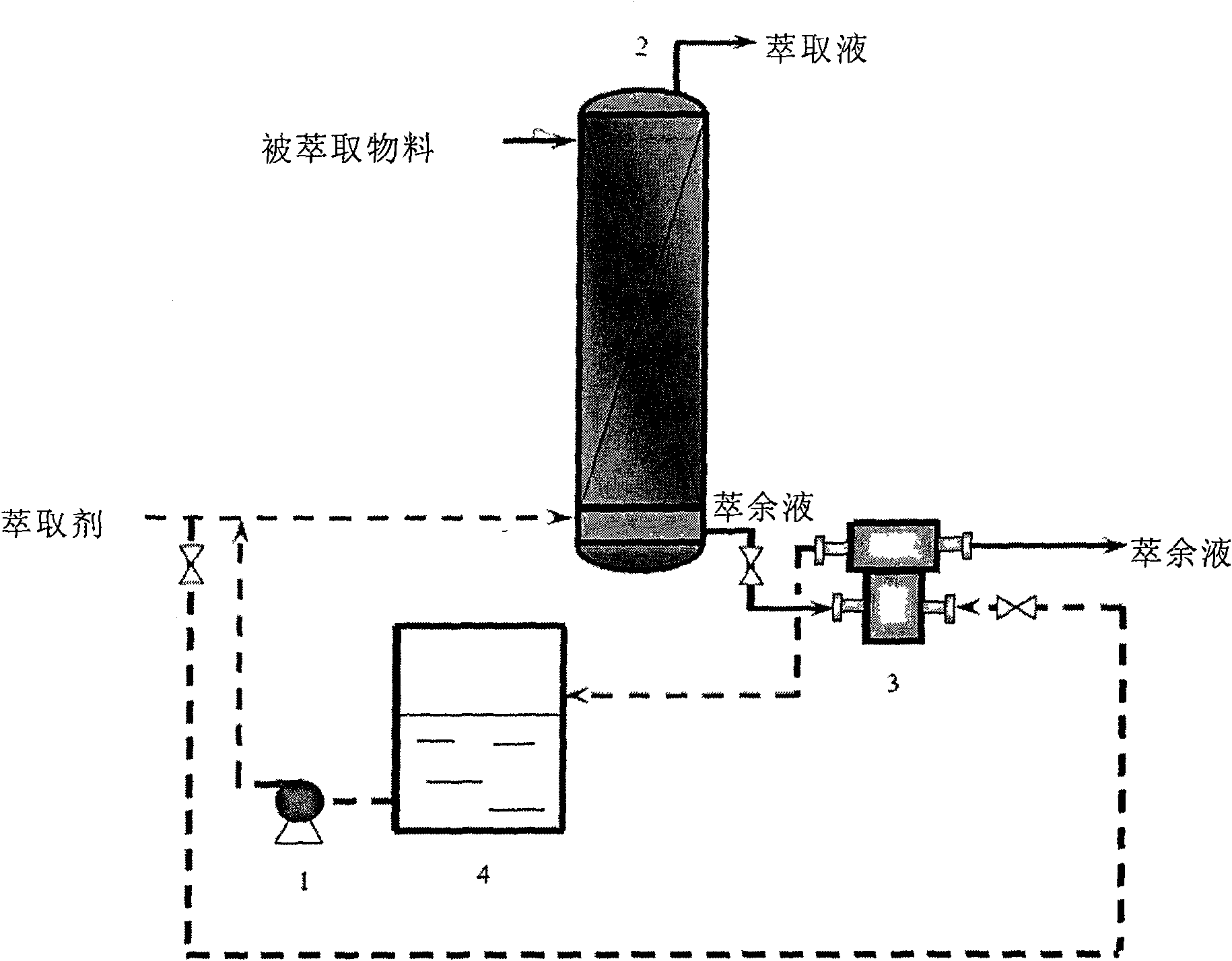

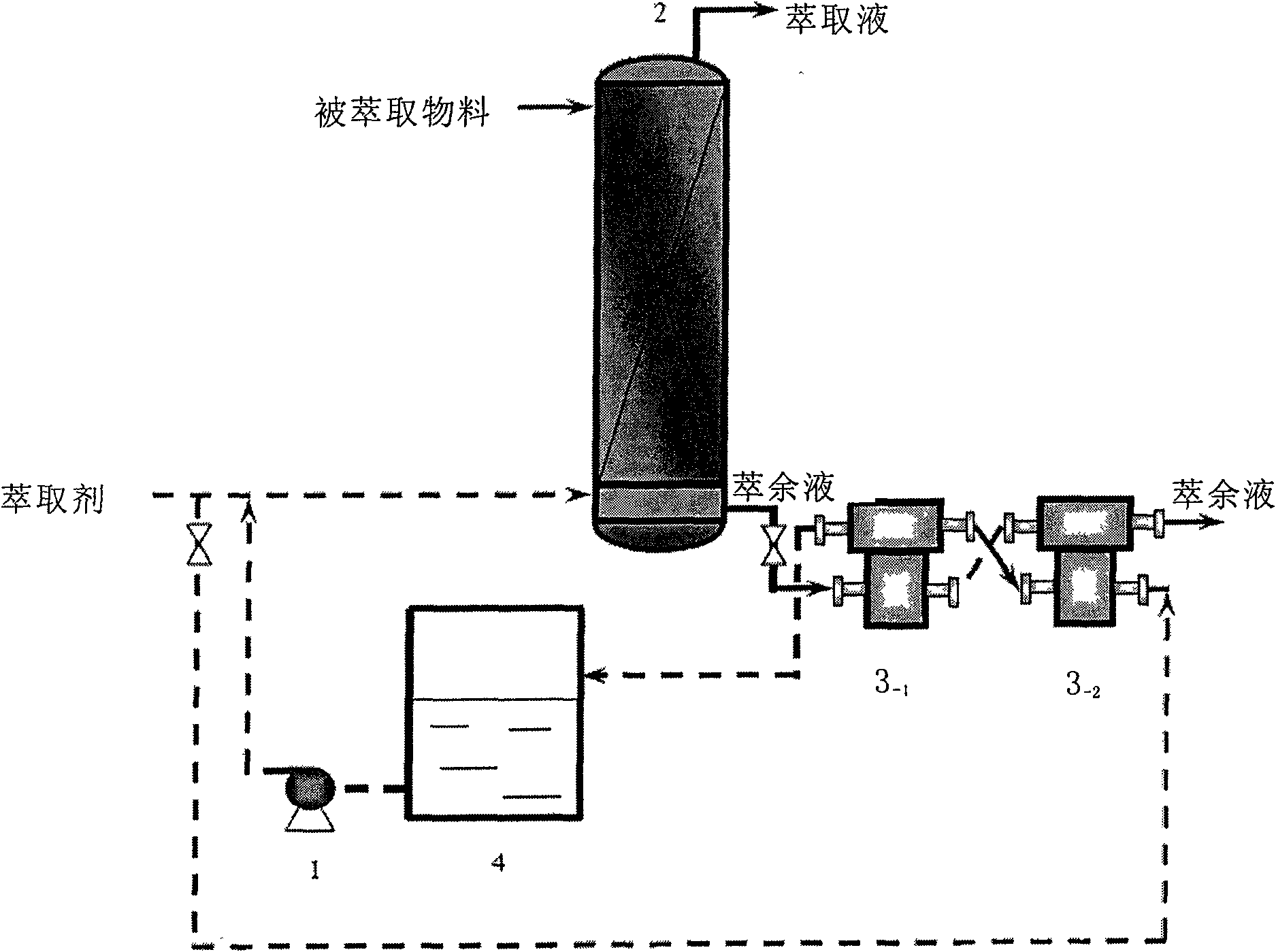

High performance liquid-solution solvent extraction method and device

InactiveCN101637669AOvercome the shortcomings of not being able to achieve deep extractionSimple structureLiquid solutions solvent extractionTowerRaffinate

The invention relates to a high performance liquid-solution solvent extraction method and a device, providing a high performance liquid-solution solvent extraction method comprising: extracting an extracted material in a tower type to obtain extract liquor and raffinate; and performing centrifugal extraction to the obtained raffinate to obtain an extraction product. The invention also provides a high performance liquid-solution solvent extraction device.

Owner:EAST CHINA UNIV OF SCI & TECH

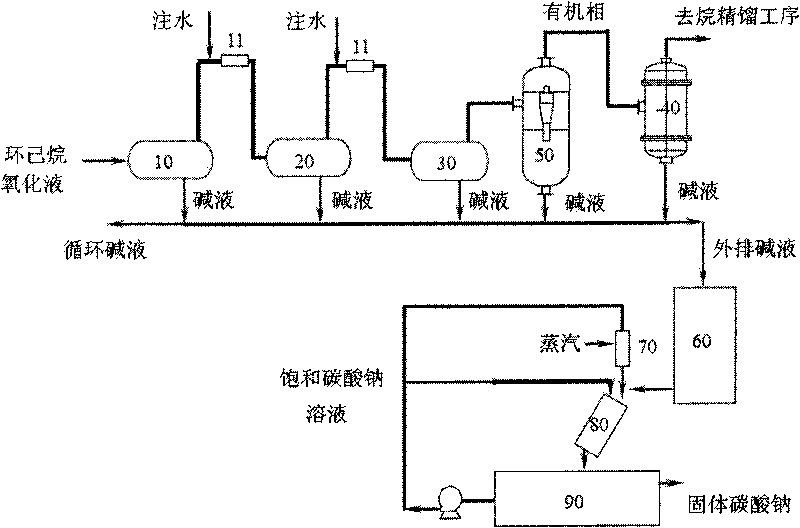

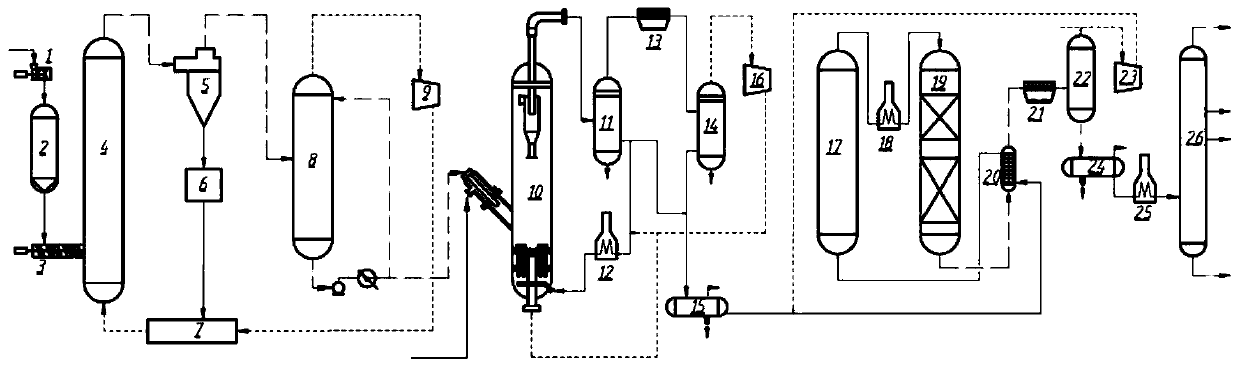

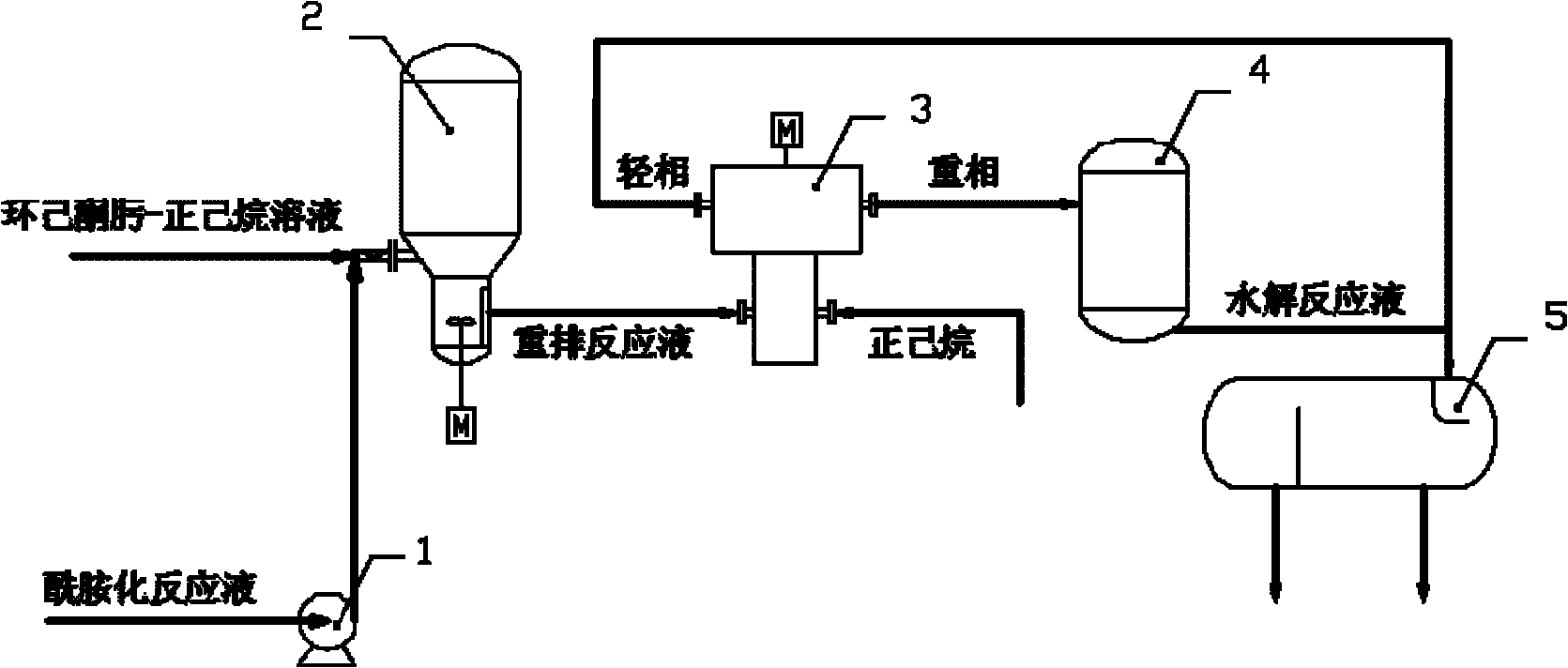

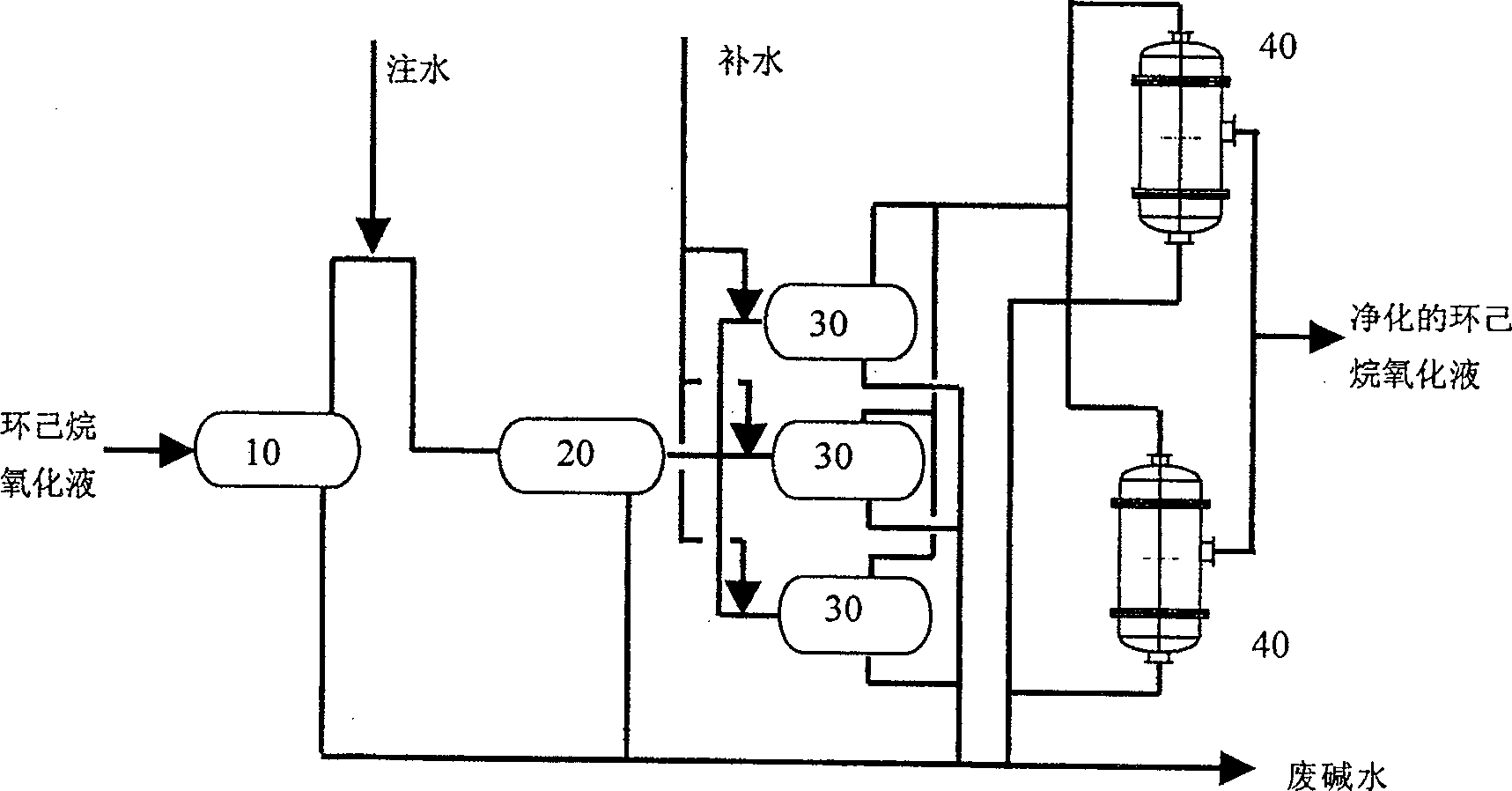

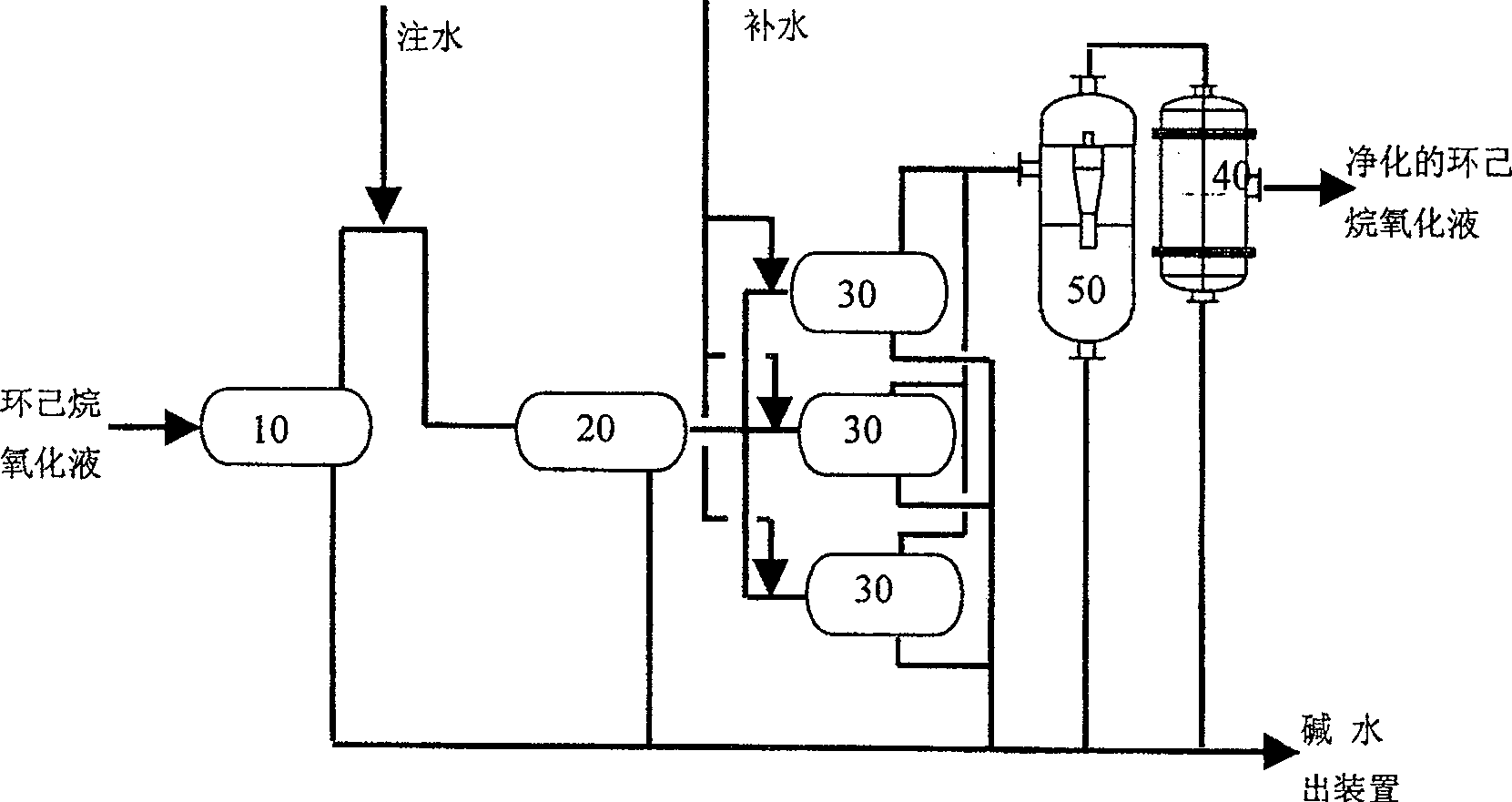

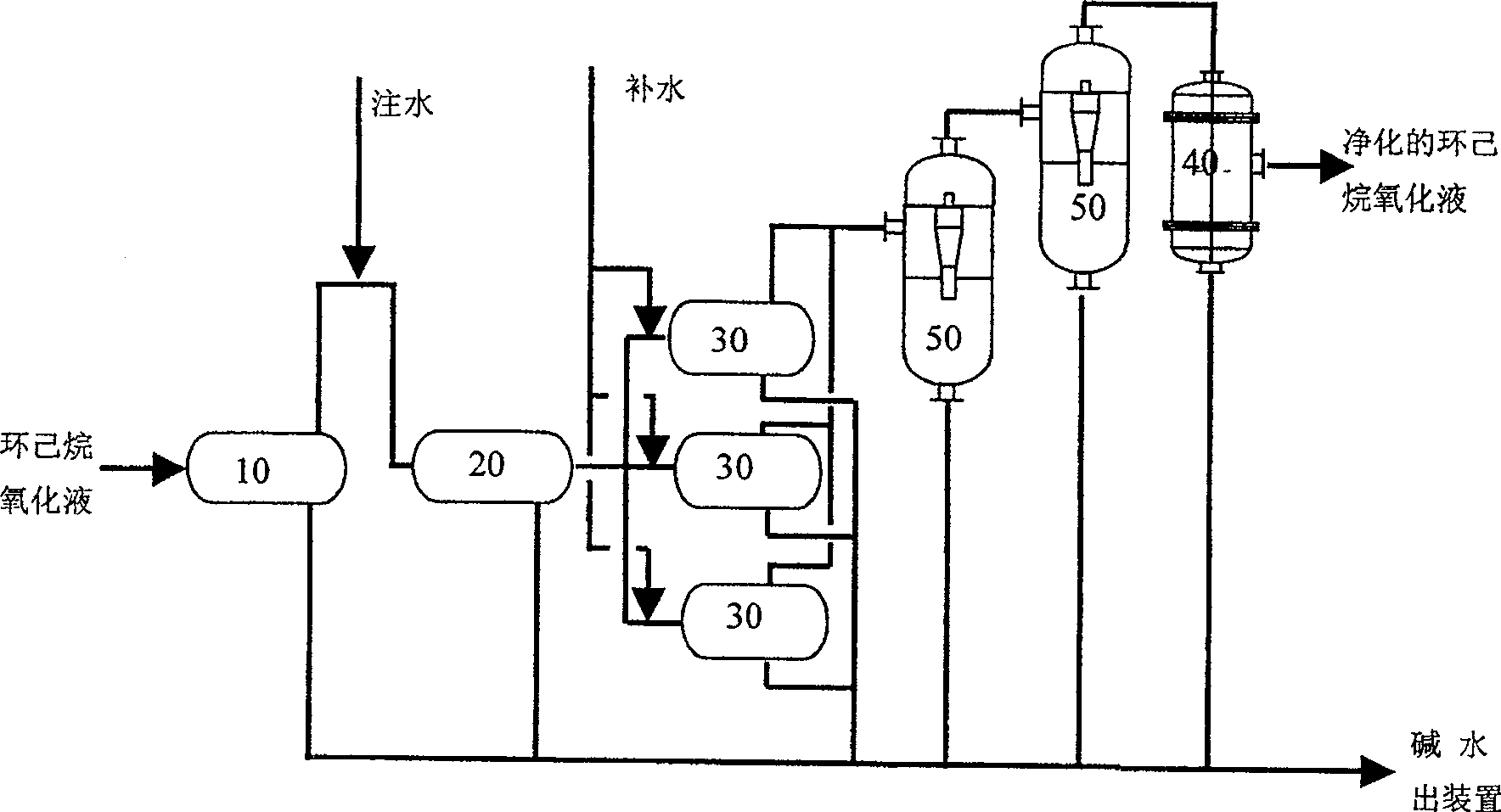

Method and device for separating and recycling alkali waste in cyclohexane oxide solution

ActiveCN101734689AExtended operating cycleEliminate emissionsOrganic compound preparationSeparation devicesAlkanePollution

The invention relates to a method and a device for separating and recycling alkali waste in cyclohexane oxide solution. In the invention, gravity settling technology, cyclone separating technology and coalescing separating technology are in gradient combination to perform fine separation to the liquid alkali waste of cyclohexane oxide solution, purified cyclohexane oxide solution is led into a downstream device; the majority of separated liquid alkali waste is recycled, part of separated liquid alkali waste is discharged, the discharged separated liquid alkali waste is incinerated in an incinerator, the fusant after ncineration is recycled by using pneumatic nebulization process. The invention can reduce the Na+ content in the cyclohexane oxide solution entering into the alkane tower to below 3mg / L, the fusant after ncineration is recycled by 100%, and the pollution to the environment caused by liquid alkali waste is mainly eliminated. The invention is suitable for separating and recycling alkali waste in cyclohexane oxide solution as well as for separating and recycling alkali waste of other chemical engineering equipments.

Owner:EAST CHINA UNIV OF SCI & TECH

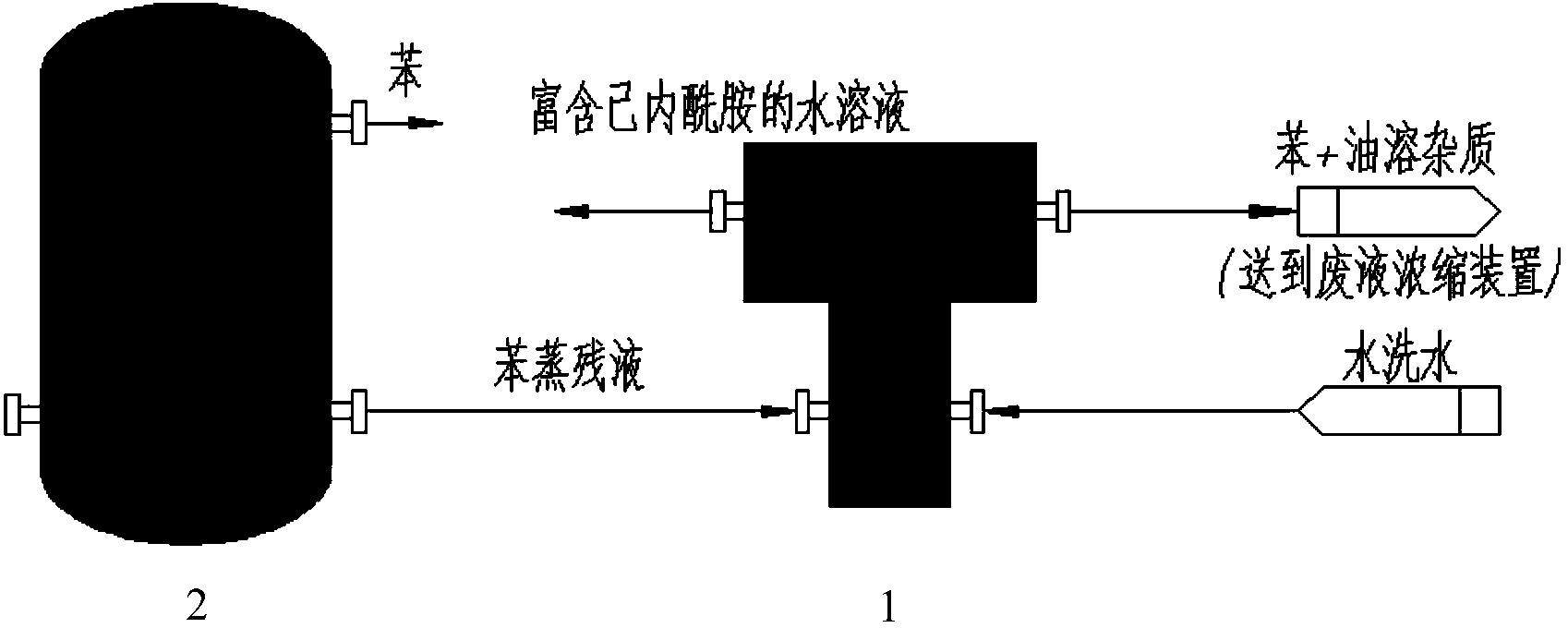

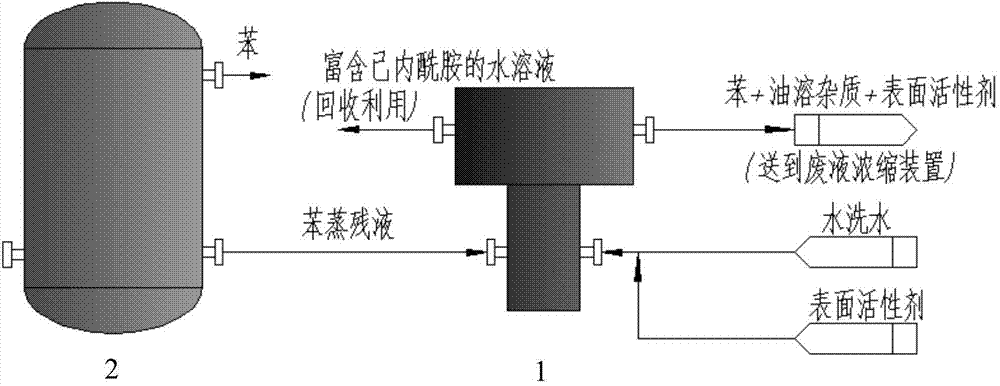

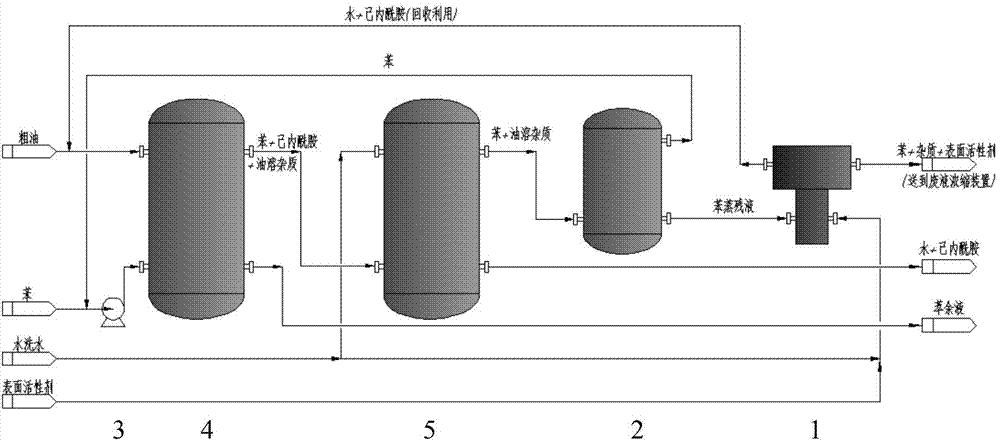

Method and device for recovering caprolactam in benzene distillation residue

InactiveCN103539738AAvoid churnIncrease productionLactams separation/purificationLiquid solutions solvent extractionBenzeneDistillation

The invention relates to a method and device for recovering caprolactam in benzene distillation residue, and provides a method for recovering caprolactam in the benzene distillation residue. The method comprises the following steps: (a) respectively feeding the benzene distillation residue and water obtained by distilling in a benzene distillation column into a centrifugal extractor; (b) enabling the benzene distillation residue and water to fully mix and be subjected to mass transfer in the centrifugal extractor, in order to extract caprolactam in benzene distillation residue into the water; (c) performing liquid-liquid separation on the mixed solution of the benzene distillation residue and water through the centrifugal extractor in order to separate out an aqueous solution rich in caprolactam and the benzene distillation residue in which the caprolactam is removed; and (d) recycling the aqueous solution rich in caprolactam, separated out in step (c), and treating the benzene distillation residue in which the caprolactam is removed, by incineration. The invention also provides the device for recovering the caprolactam in the benzene distillation residue.

Owner:EAST CHINA UNIV OF SCI & TECH

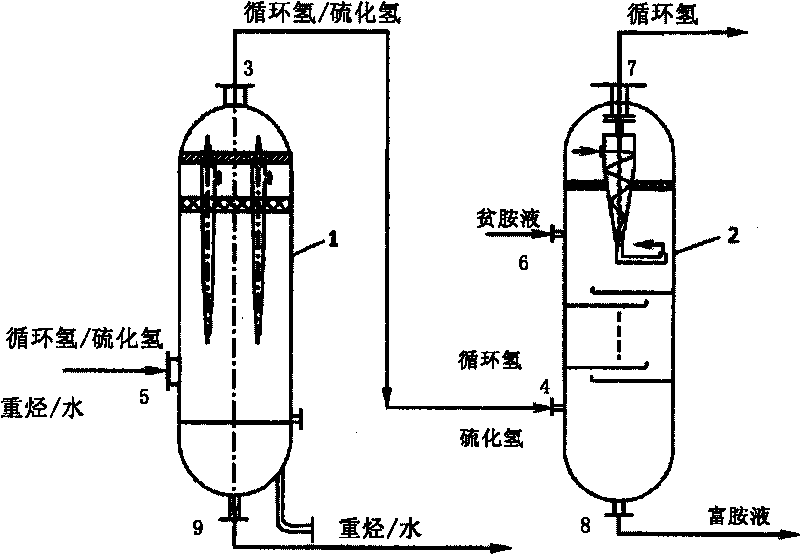

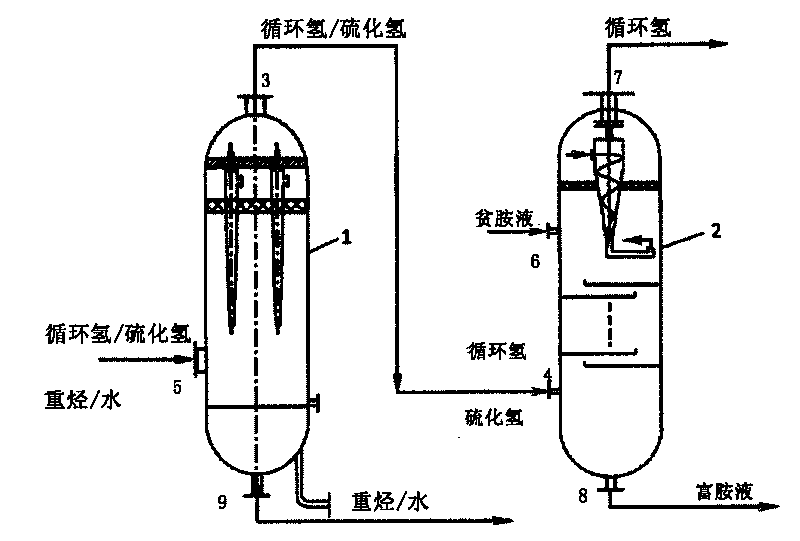

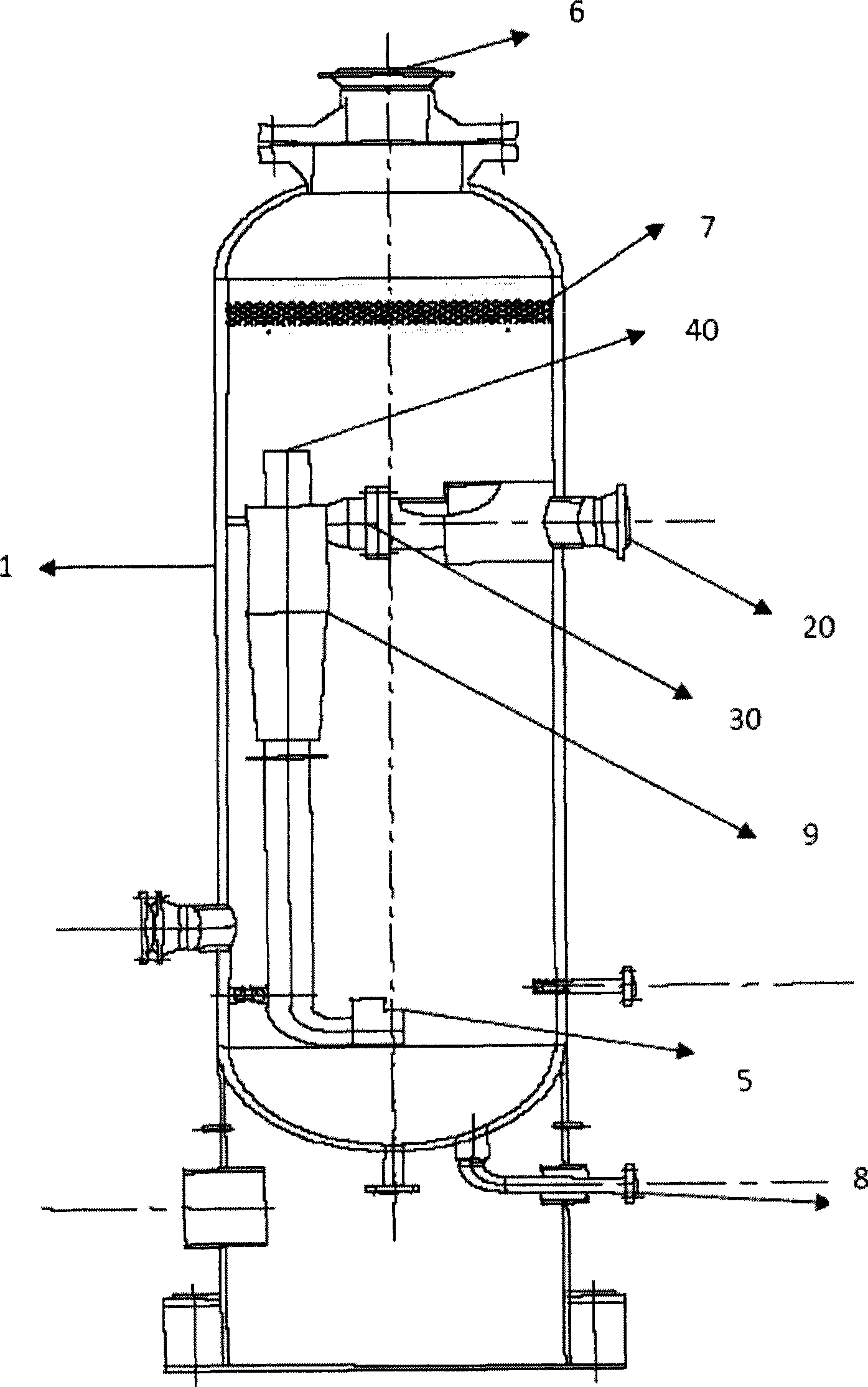

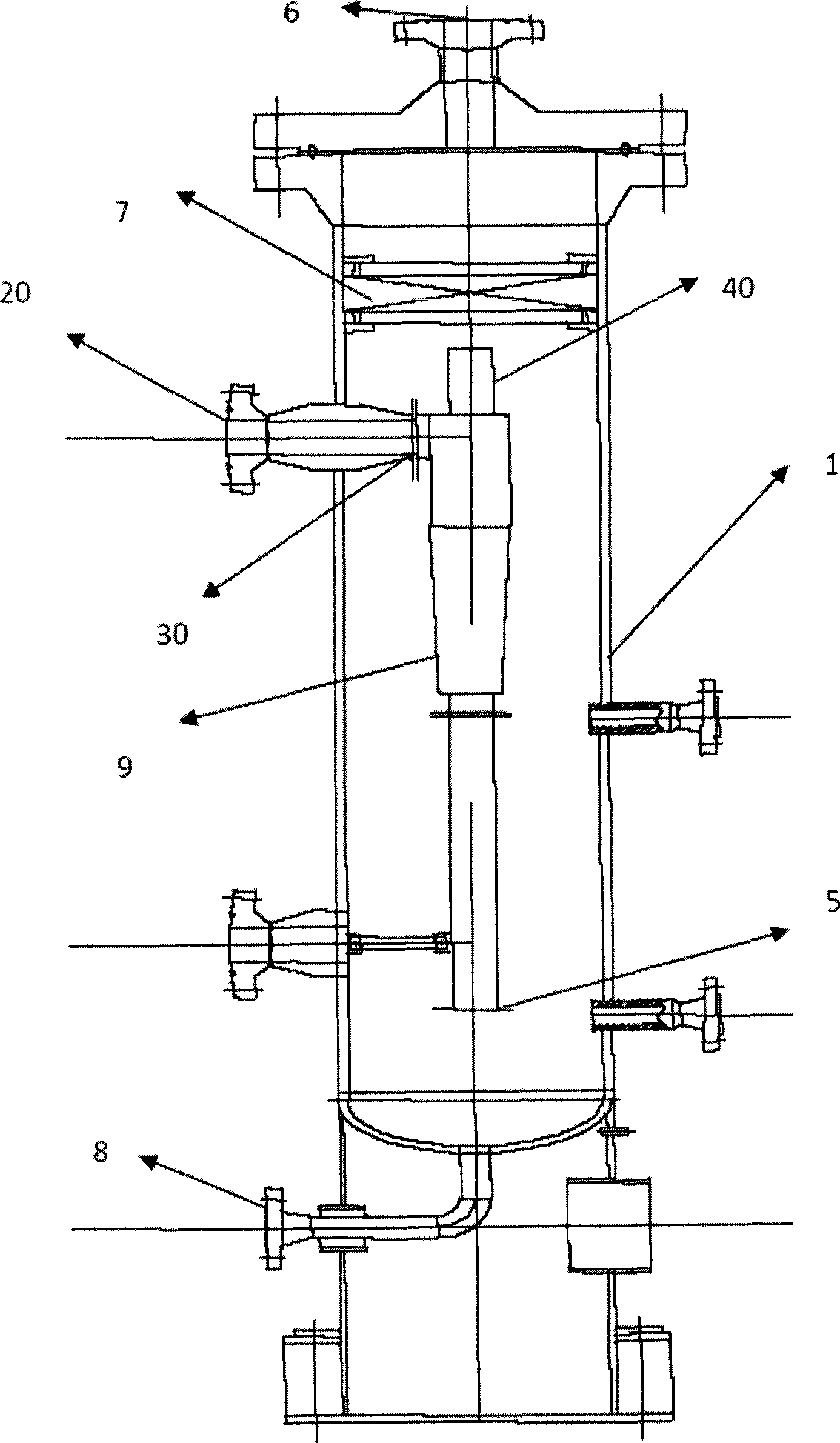

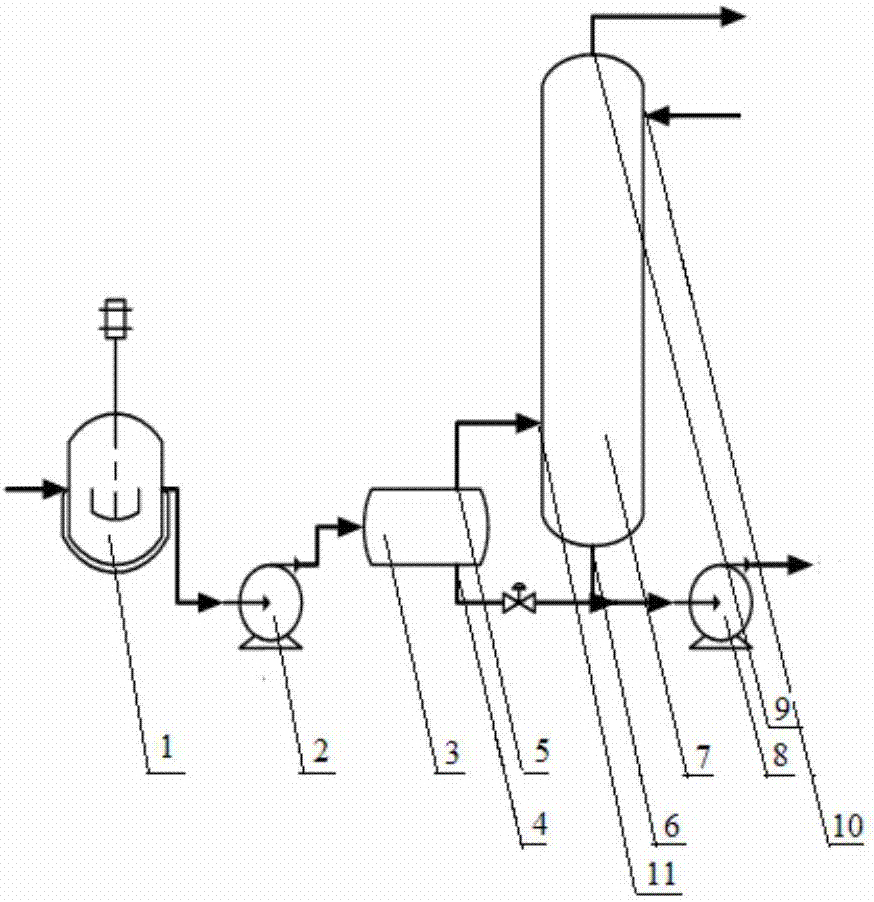

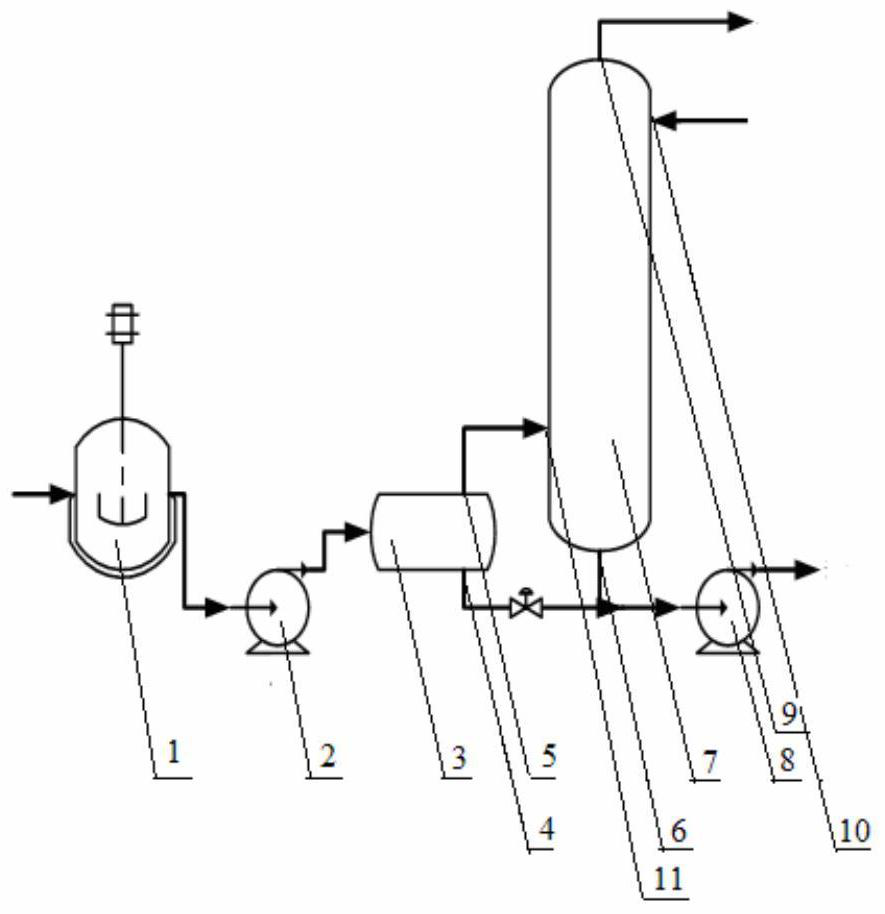

Method and device for desulphurization of recycle hydrogen

InactiveCN101721861AShorten desulfurization run timeLow investment costHydrogen separationDispersed particle separationHydrogenSulfur

The invention relates to a method and a device for the desulphurization of recycle hydrogen. The invention provides a method for the desulphurization of the recycle hydrogen, which comprises the following steps: conveying the recycle hydrogen mixture into a high-pressure separator of an internal cyclone separator to remove liquid and solid particles carried by the mixture; and delivering the recycle hydrogen mixture from which the liquid and the solid particles are removed into a desulfurizer to remove sulfur carried by the mixture, wherein the high-pressure separator and the desulfurizer are transversely arranged or longitudinally and coaxially overlapped. The invention also provides a device for the desulphurization of the recycle hydrogen.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

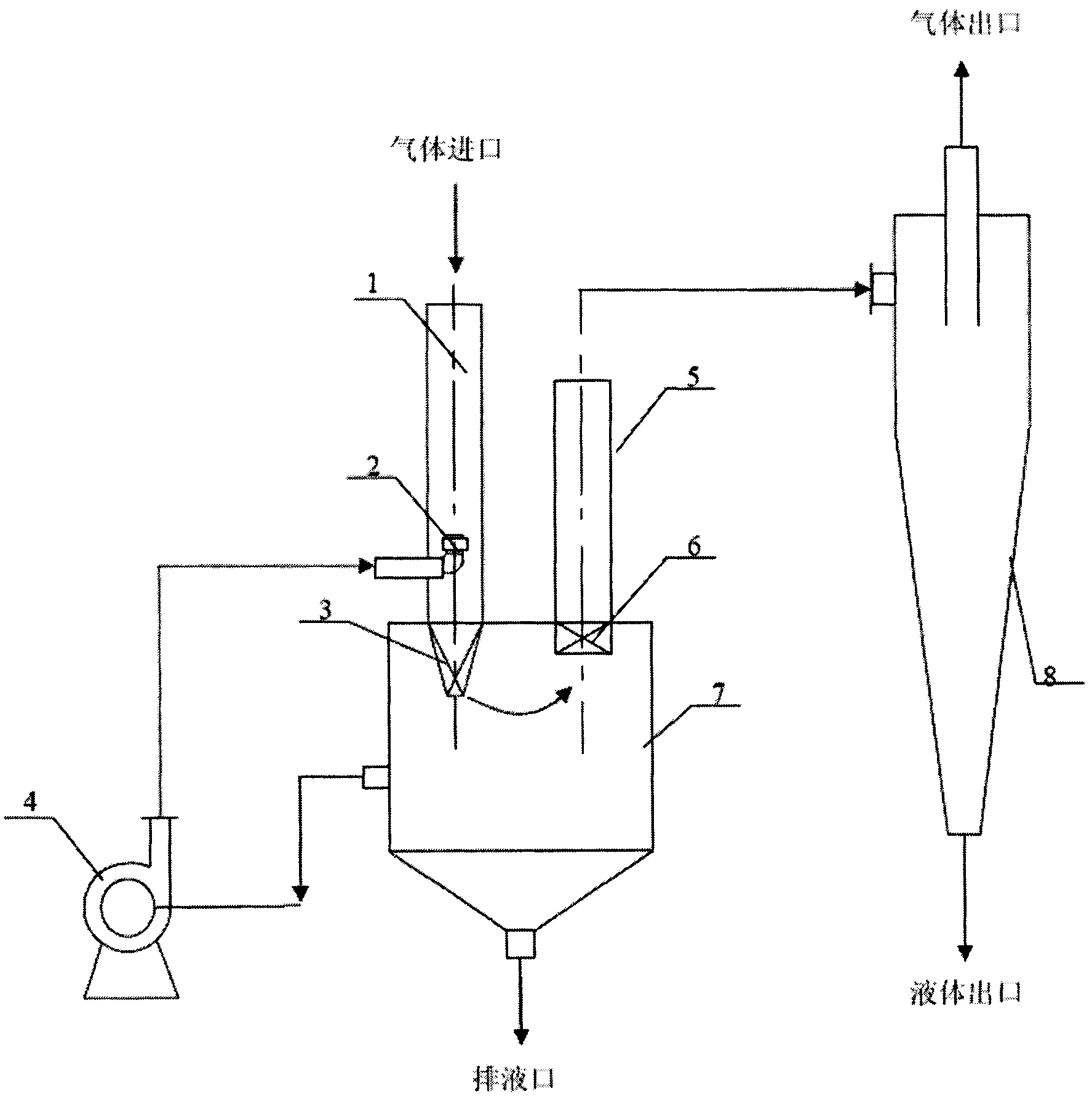

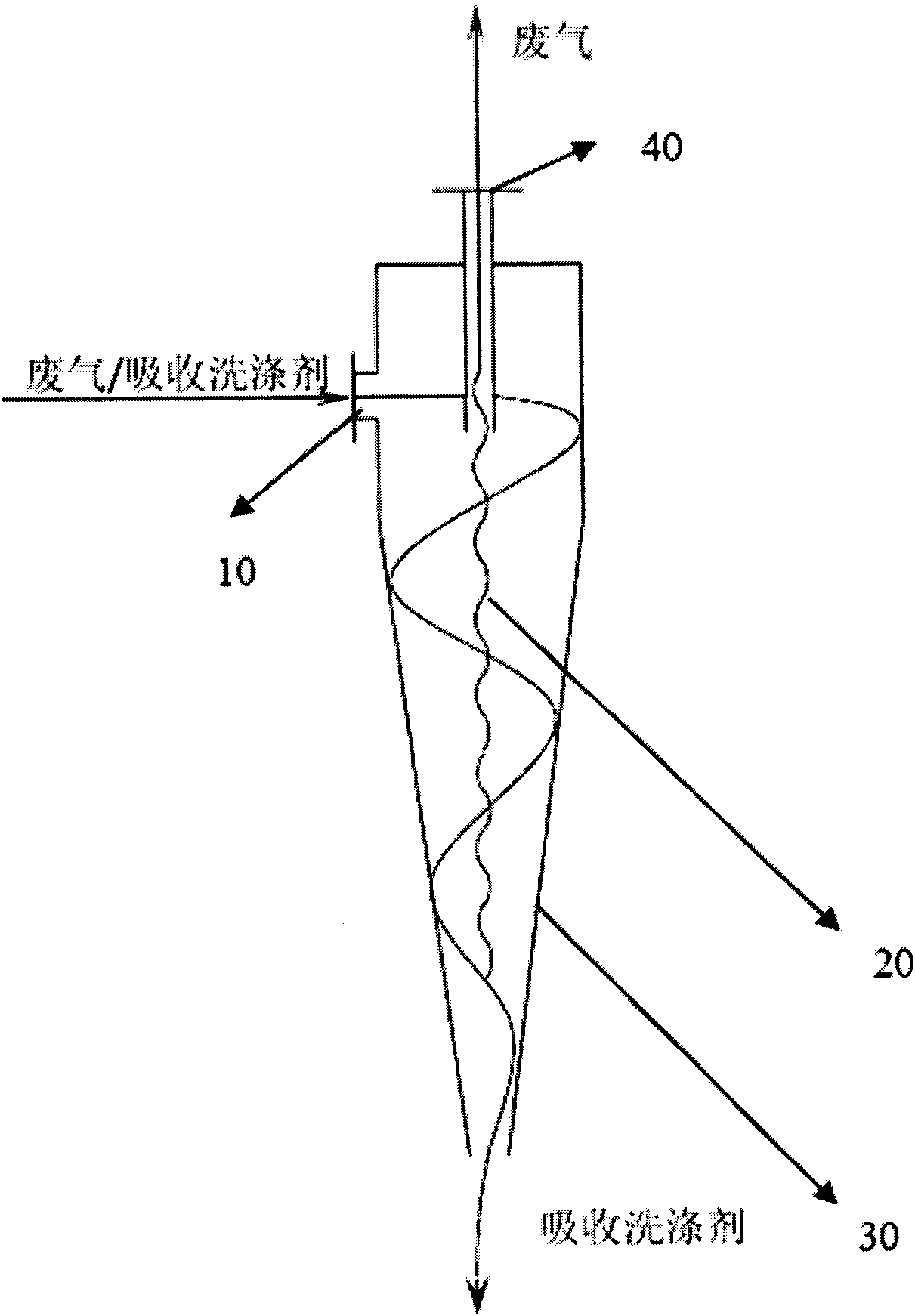

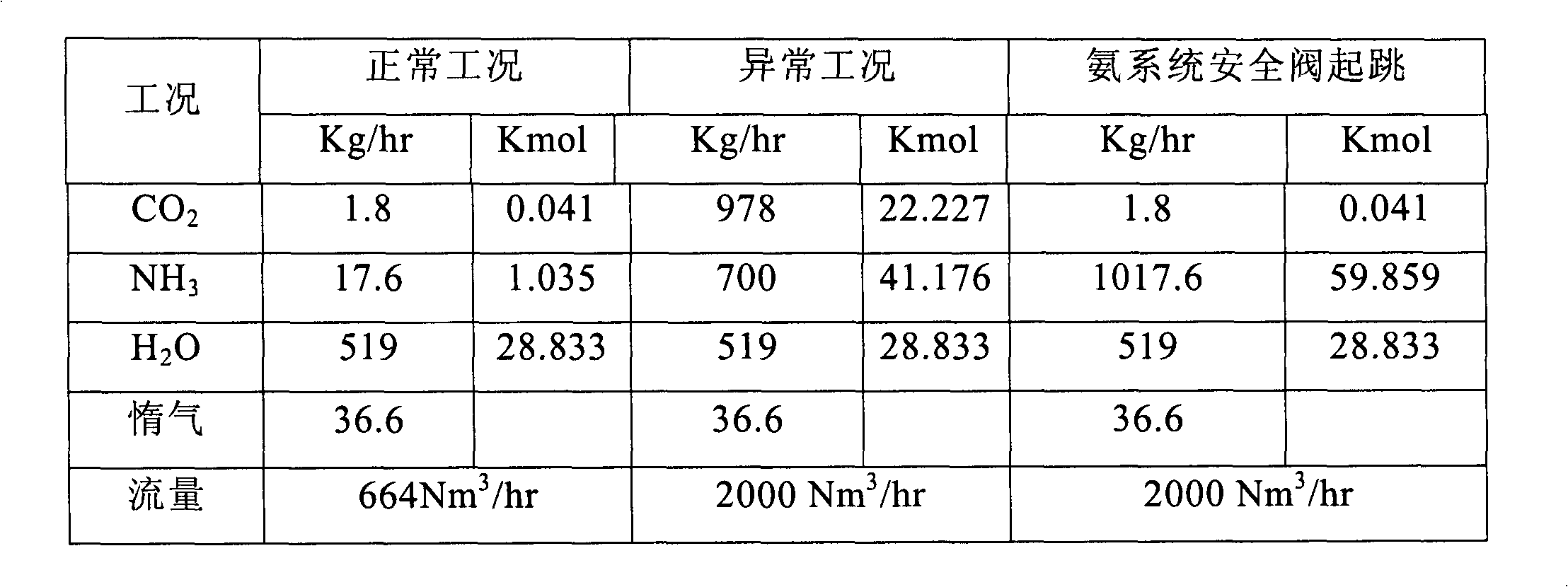

Method and device for absorbing and whirling waste gas

InactiveCN101912715AEmission reductionReduce running lossDispersed particle separationProduct gasMixed gas

The invention relates to a method and a device for absorbing and whirling waste gas, providing a method for absorbing and whirling the waste gas. The method comprises the steps of: subjecting hydrophilic gas-containing waste gas and absorptive detergent to countercurrent contact for turbulent mixing of gas and liquid phases; subjecting mixed gas to fair current washing for removing hydrophilic gas; and subjecting waste gas including the absorptive detergent to whirling separation for removing the absorptive detergent included in the waste gas. The invention also provides the device for absorbing and whirling the waste gas.

Owner:EAST CHINA UNIV OF SCI & TECH

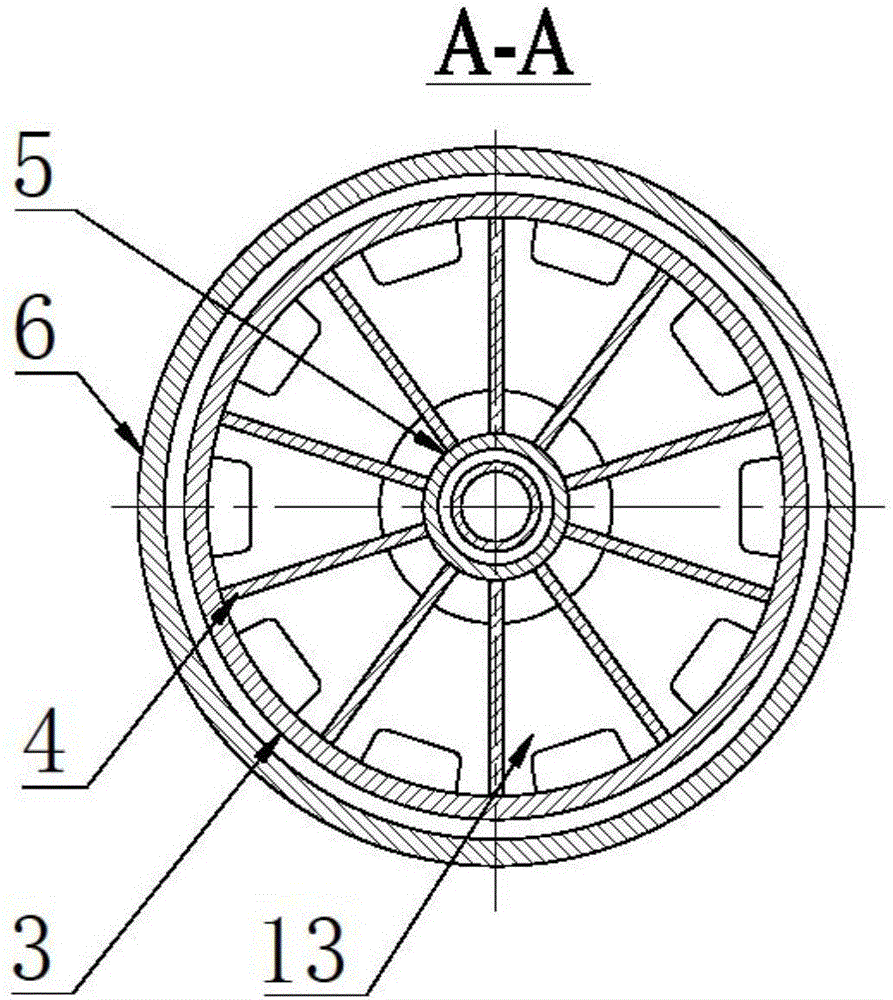

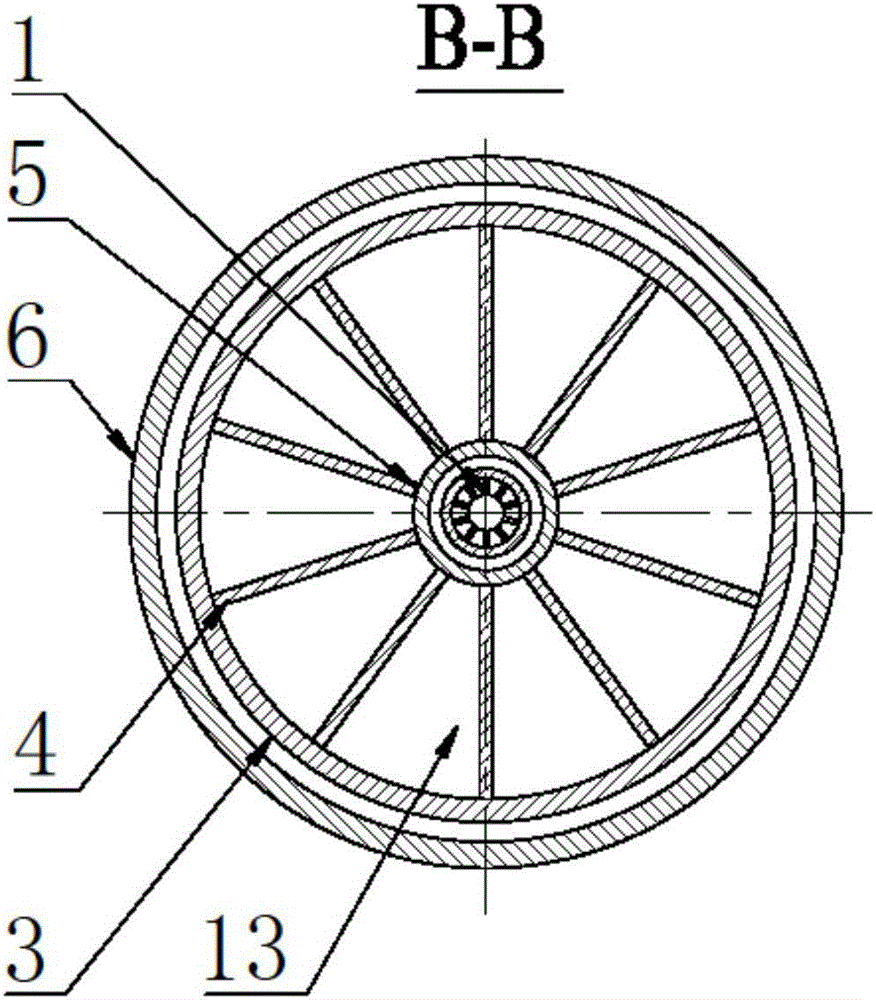

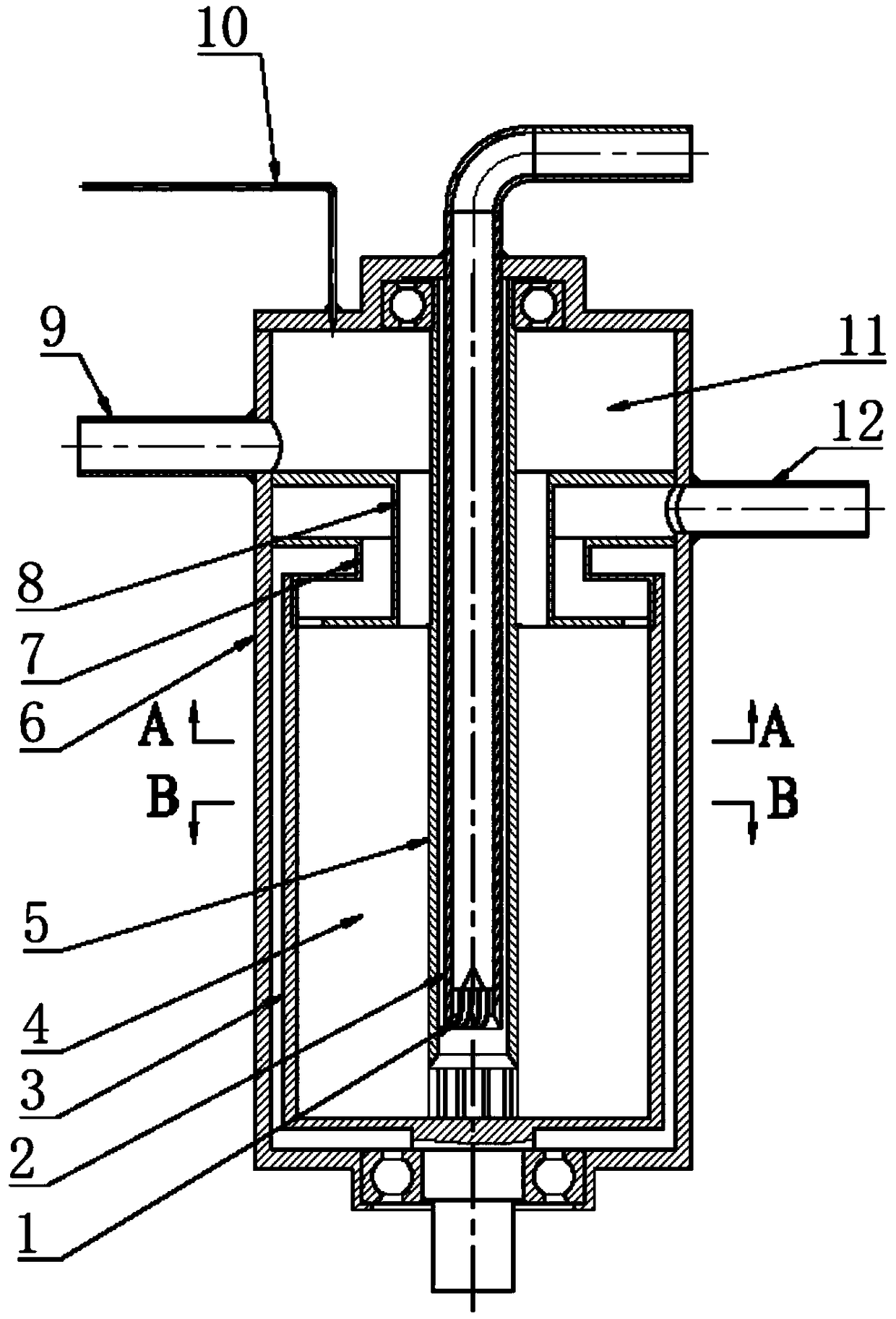

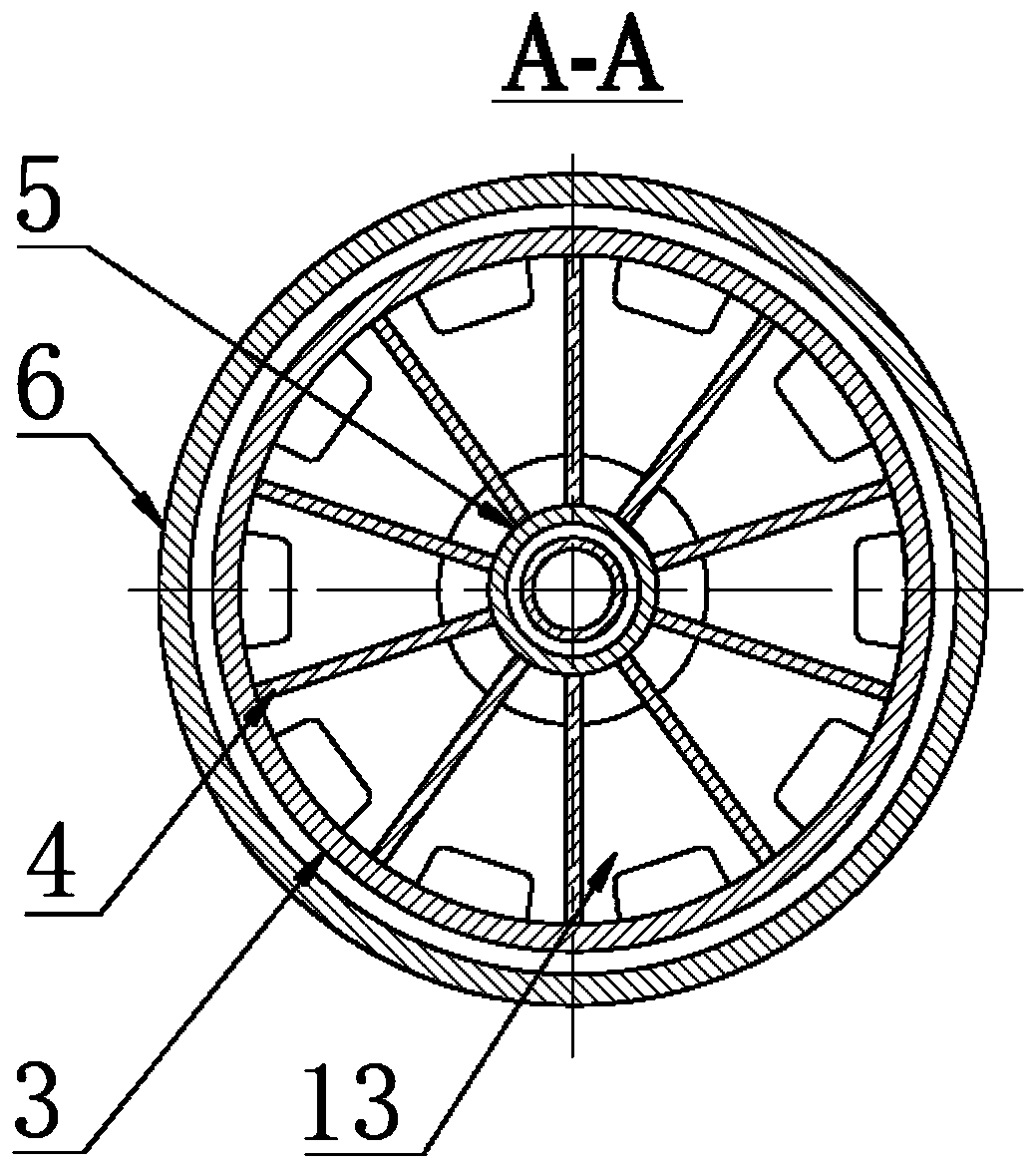

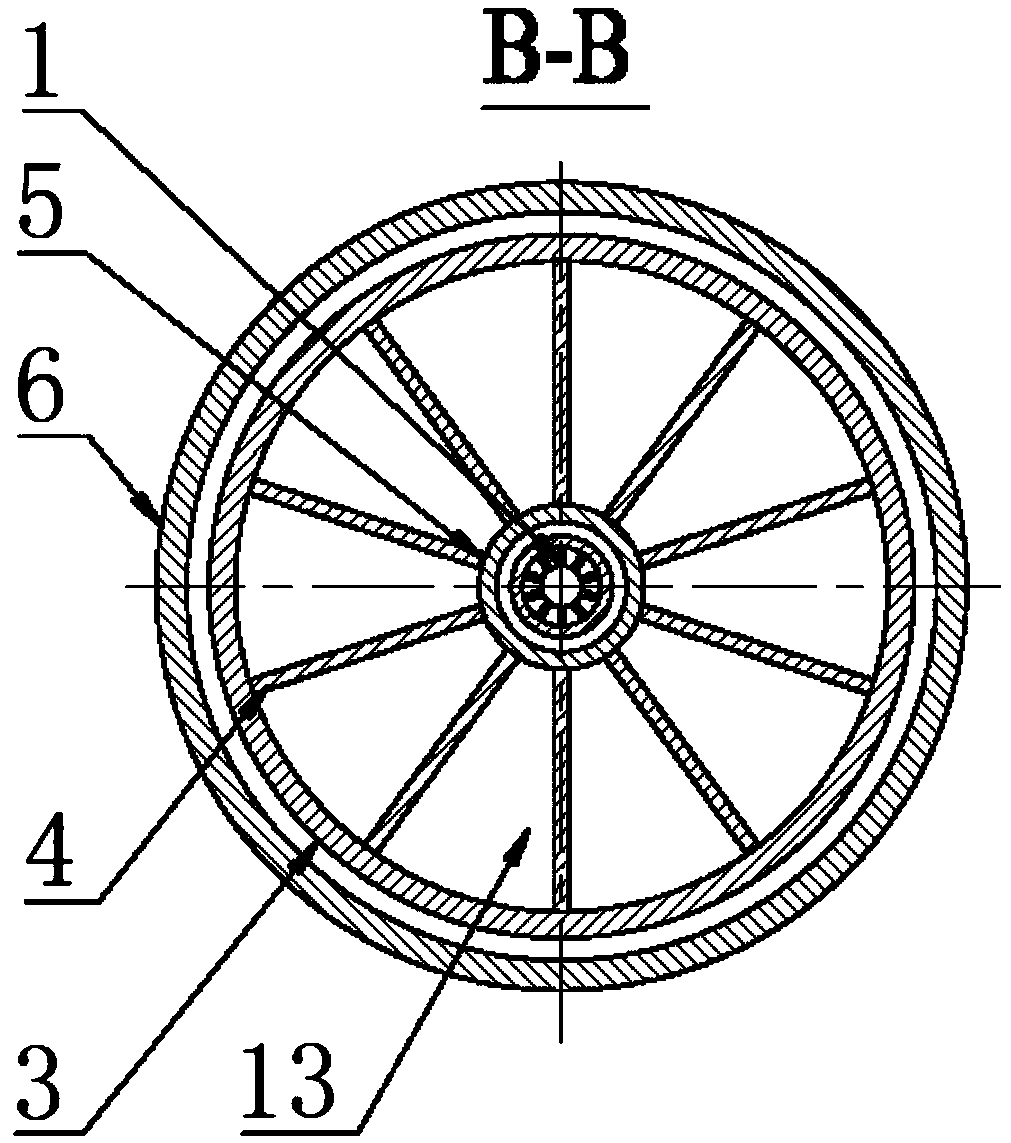

Solid vortex centrifugal separation device and oil spillingskim separating method thereof

The invention discloses a solid vortex centrifugal separation device and an oil spillingskim separating method thereof. The solid vortex centrifugal separation device comprises an outer support, a columnar rotary drum, an inlet pipeline, a pre-rotary guide vane, gratings, a central fixing shaft, a water phase overflow weir, an oil phase overflow weir, a water phase outlet pipe, an oil phase outlet pipe and a gas phase outlet pipe, wherein the inlet pipeline and the columnar rotary drum are coaxial, the pre-rotary guide vane is arranged at the tail end of the inlet pipeline, and the columnar rotary drum is divided into a plurality of mutually independent fan-shaped separation zones by the gratings. The columnar rotary drum is driven to rotate and produce a centrifugal force by adopting an electric motor so as to perform gradual water phase and oil phase separation, a separated oil phase flows into the oil phase outlet pipe through the oil phase overflow weir and is discharged into an oil storage cabin of an oil spilling chip. Water reaching the standard is directly discharged out through the water phase overflow weir and the water phase outlet pipe. Theseparation device is small in size, good in applicability, stable in operation and high in separation efficiency, can achieve efficient oil and water separation without any reagent and meets the requirements of oily water separating devices for oil spilling ships, and the separation efficiency can be up to 99%.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

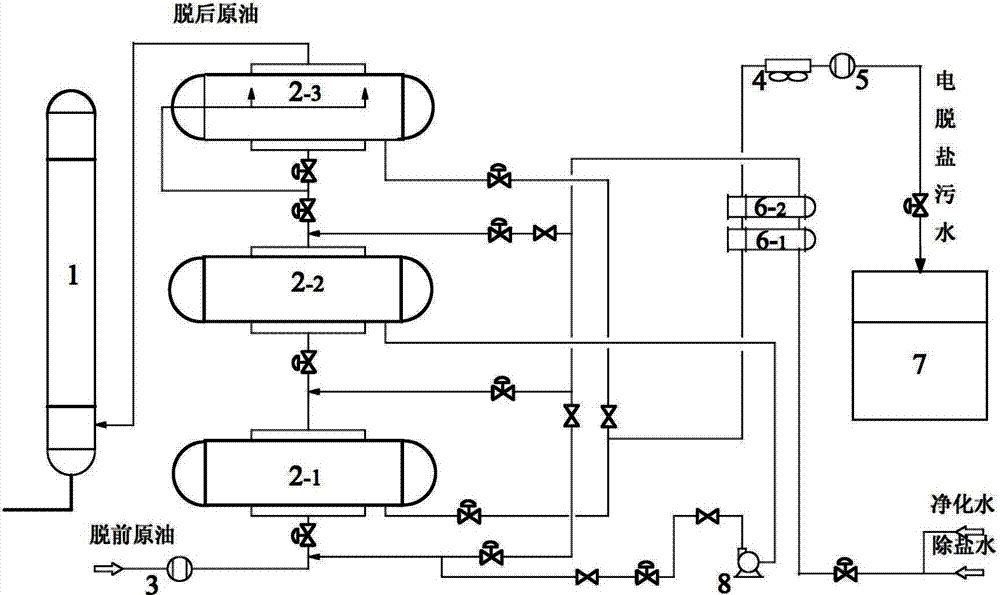

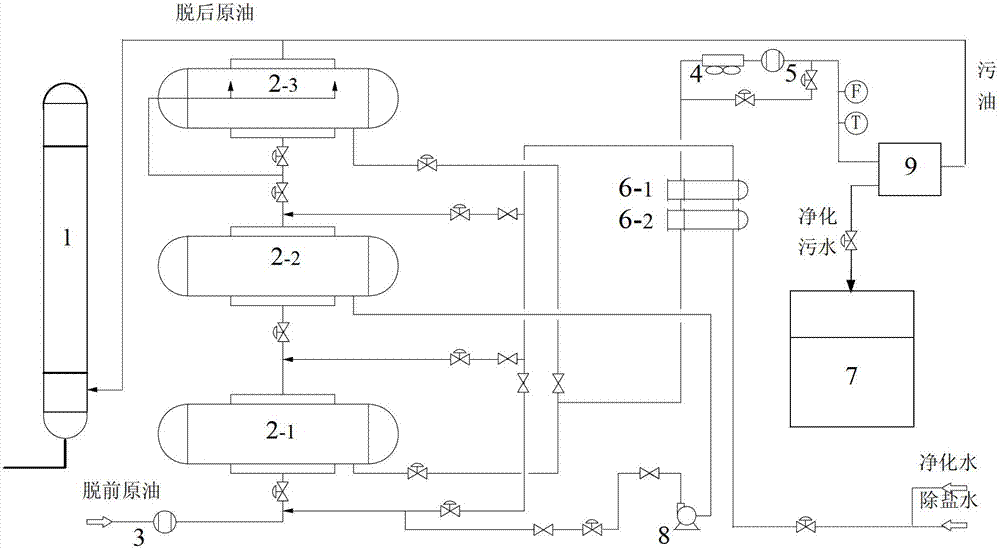

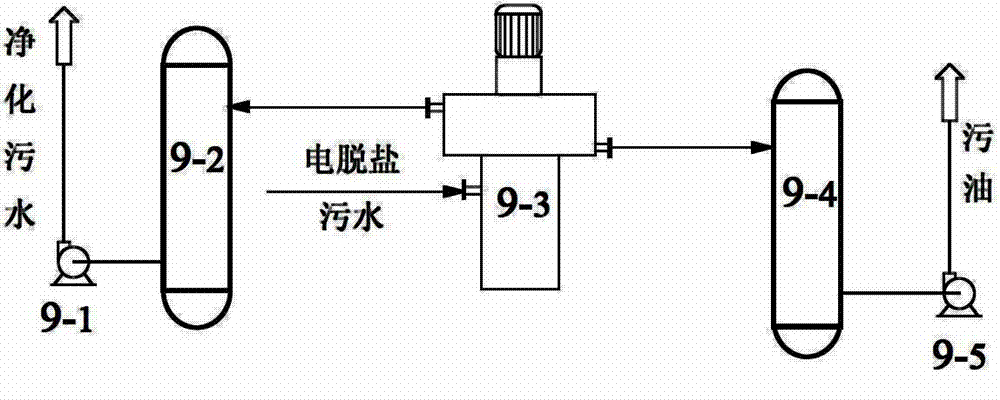

Crude oil processing unit containing electro-desalted sewage oil remover and method of crude oil processing unit

InactiveCN102757813AEasy to separateFast separationWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesDesalterOil phase

The invention relates to a crude oil processing unit containing an electro-desalted sewage oil remover, and a method of the crude oil processing unit. The crude oil processing unit includes an electrical desalter and a primary tower, wherein the electrical desalter is provided with a crude oil inlet, an oil outlet and a water drain outlet; the primary tower is provided with an oil phase inlet; and the oil outlet of the electrical desalter is communicated with the oil phase inlet of the primary tower. The crude oil processing unit is characterized in that the electrical desalter is further connected with the primary tower through a centrifugal separation unit so as to separate water and oil in electro-desalted sewage; and the centrifugal separation unit includes an inlet, an oil phase outlet and a water phase outlet, wherein the inlet of the centrifugal separation unit is connected with the water drain outlet of the electrical desalter, and the oil phase outlet of the centrifugal separation unit is communicated with the oil phase inlet of the primary tower. The crude oil processing unit and the method thereof overcome the defects that the present electro-desalted sewage oil removing method and equipment are complicated to operate, have poor effects, good separation effect and high separation speed, are convenient to operate and suitable for long-period operation, realize on-site oil removal of the electro-desalted sewage and recycle of the dirty oil, and have high applicability and high impact resistance.

Owner:EAST CHINA UNIV OF SCI & TECH

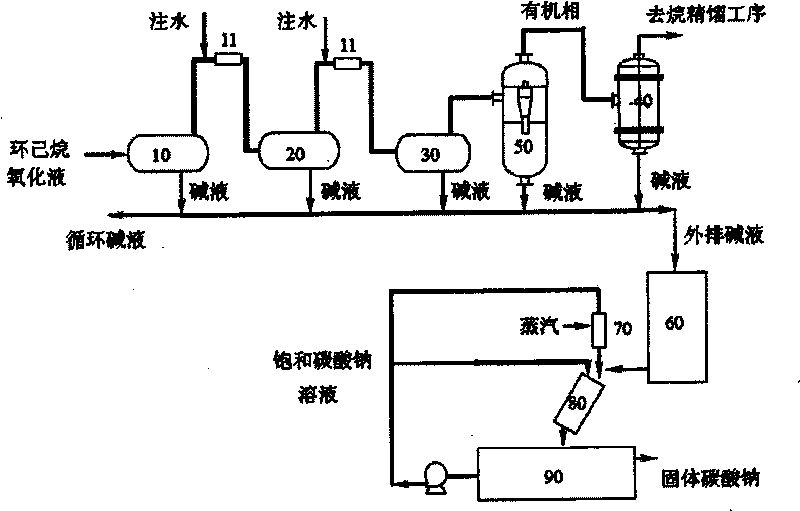

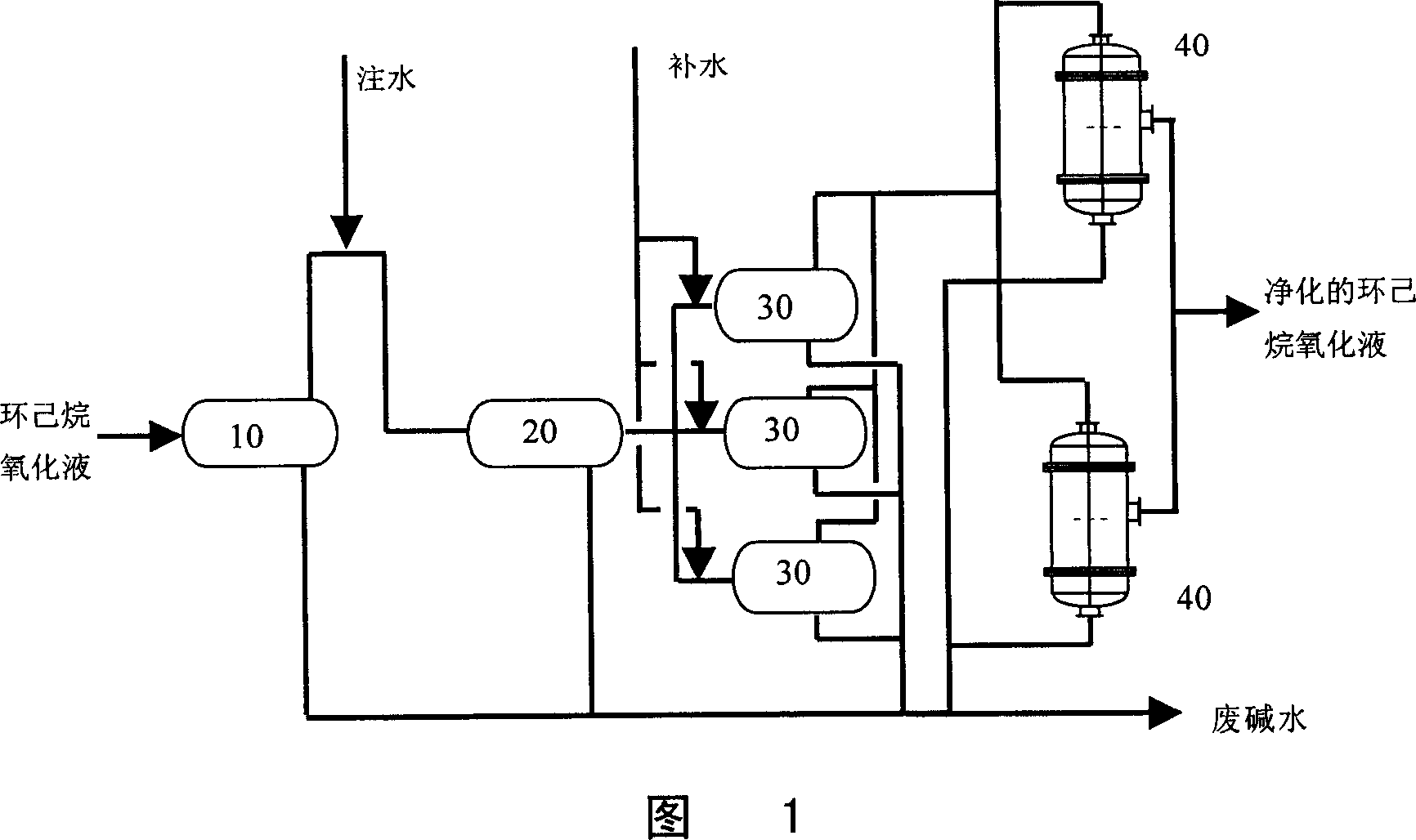

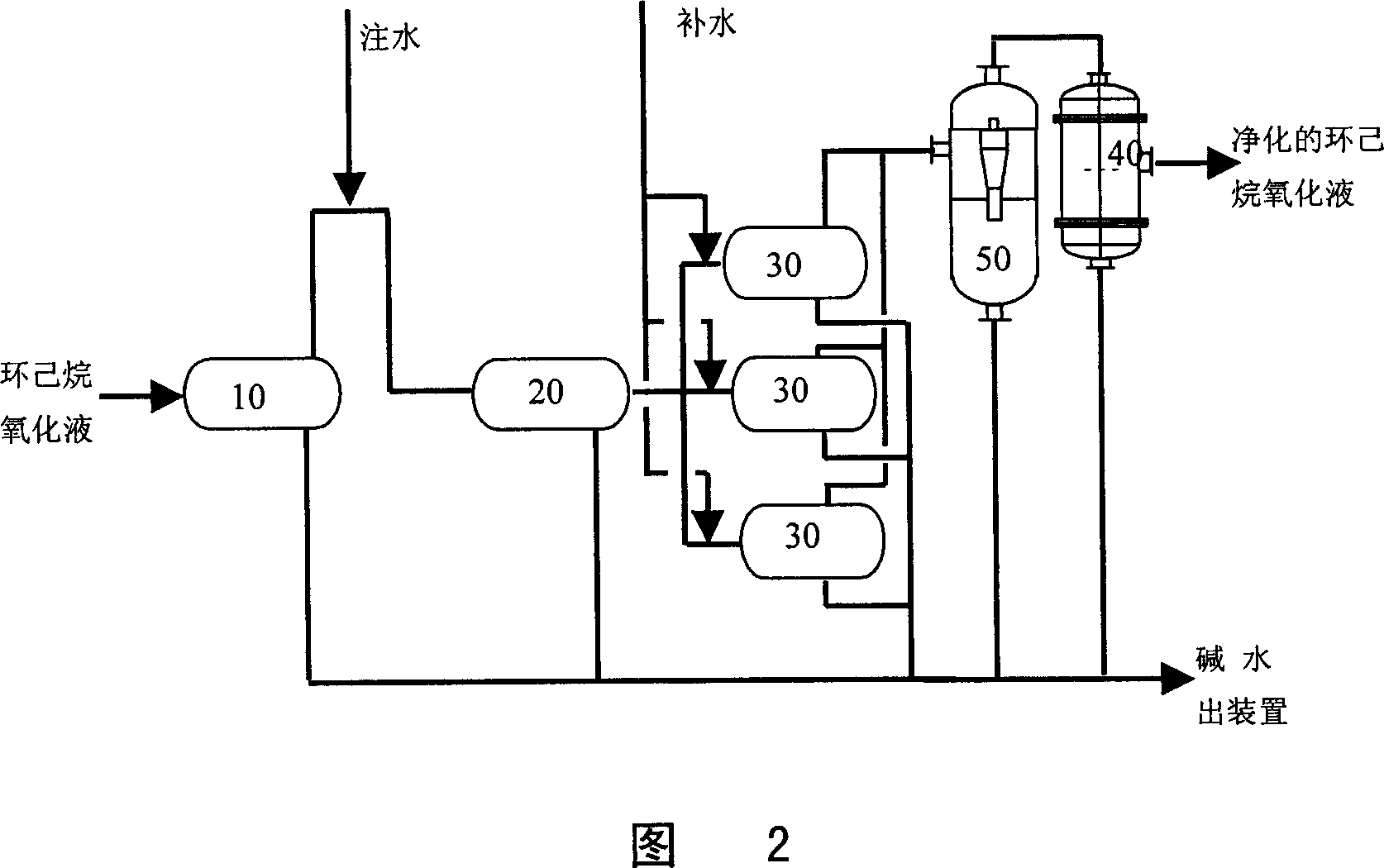

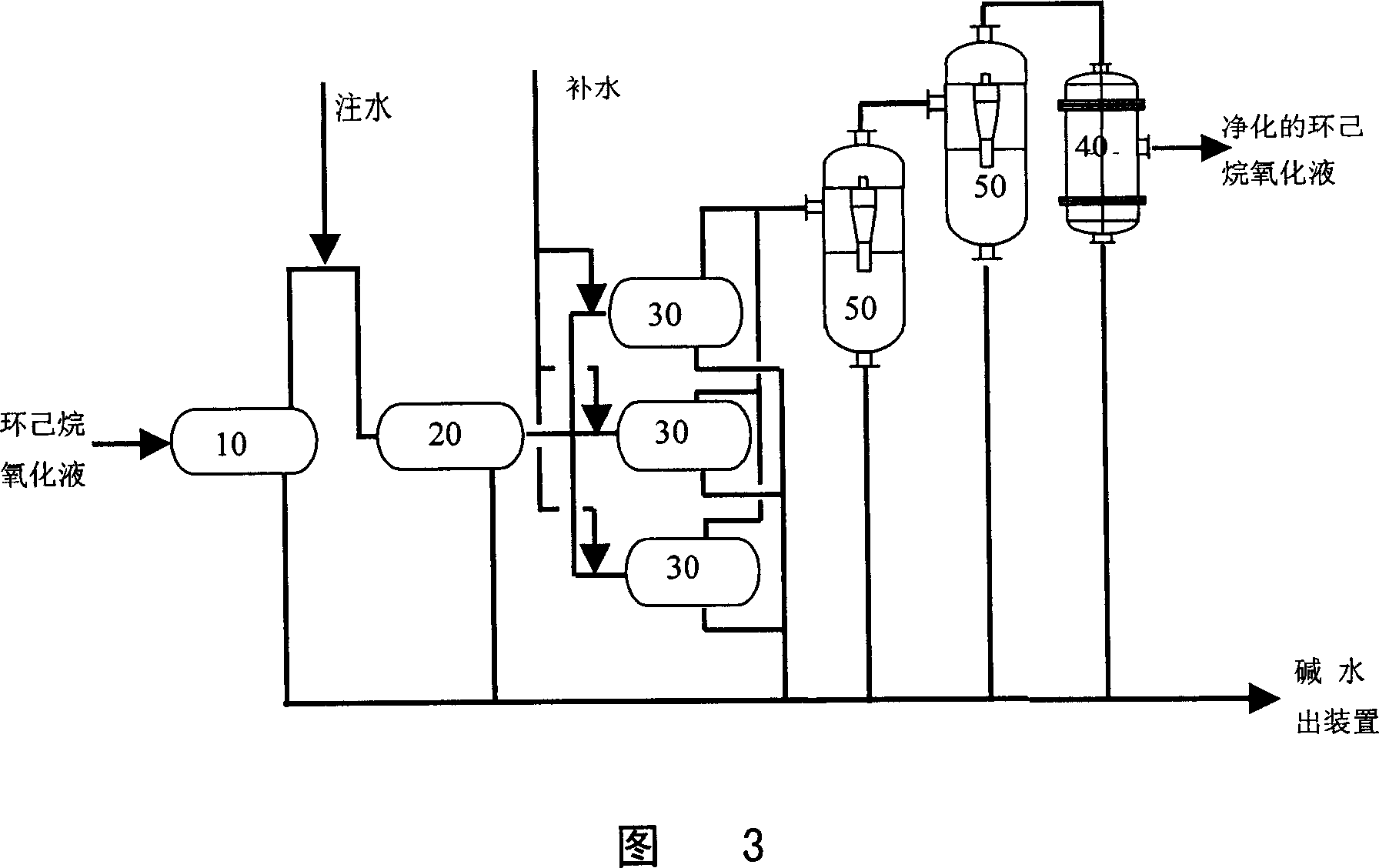

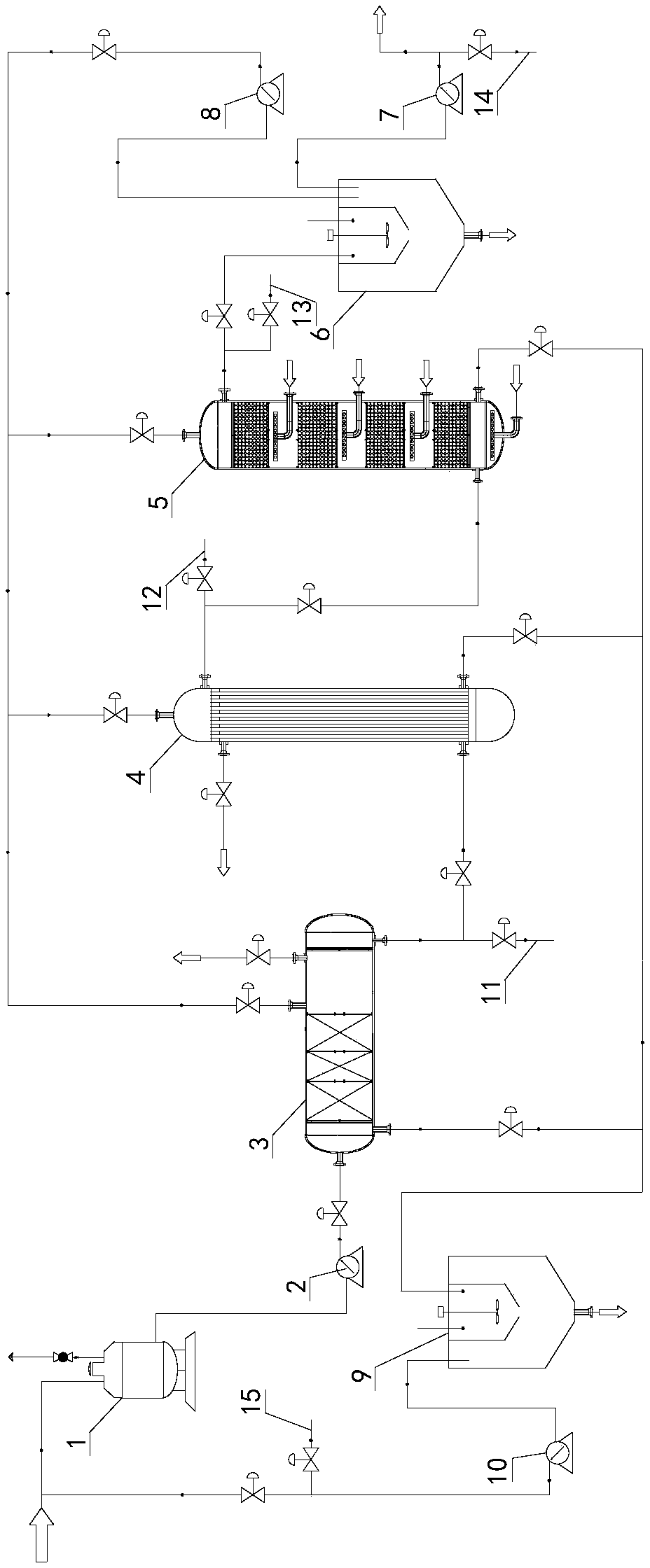

Method and apparatus for separating cyclo-hexane oxidation waste alkali

ActiveCN1978345ASolve the incomplete separationIncrease effective production timeWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentDistillationCombined use

This invention provides a method and a device for separating waste alkali of cyclohexane oxidation liquid by a spiral-flow coalescence serial combination technology, which separates it in three steps in gravity sedimentation tank, a cyclone separator and a coalescence separator to separate it completely, which overcomes the shortcomings of gravity deposition method and the coalescence separation method and prolongs the effective production time of alkyl distillation tower greatly.

Owner:EAST CHINA UNIV OF SCI & TECH

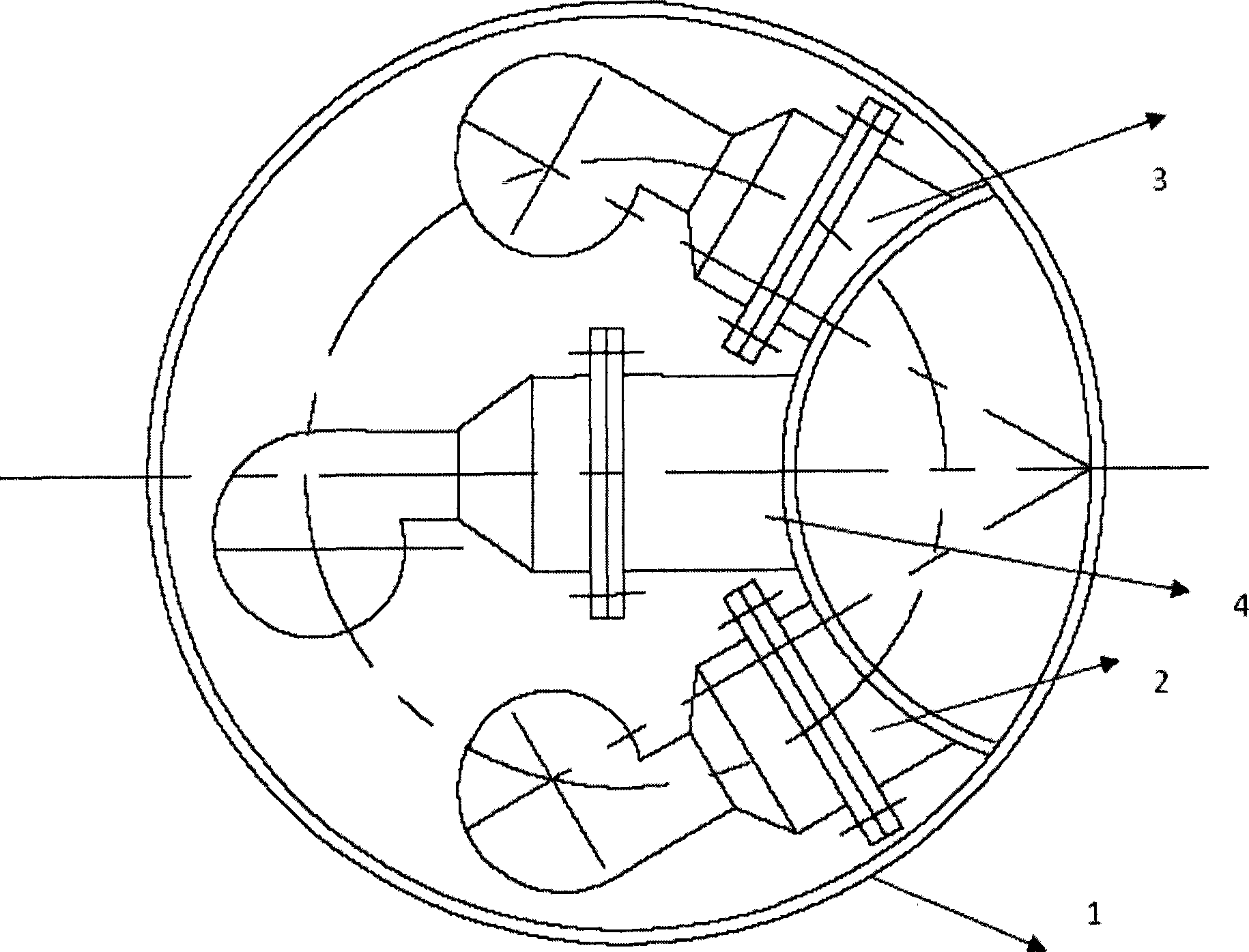

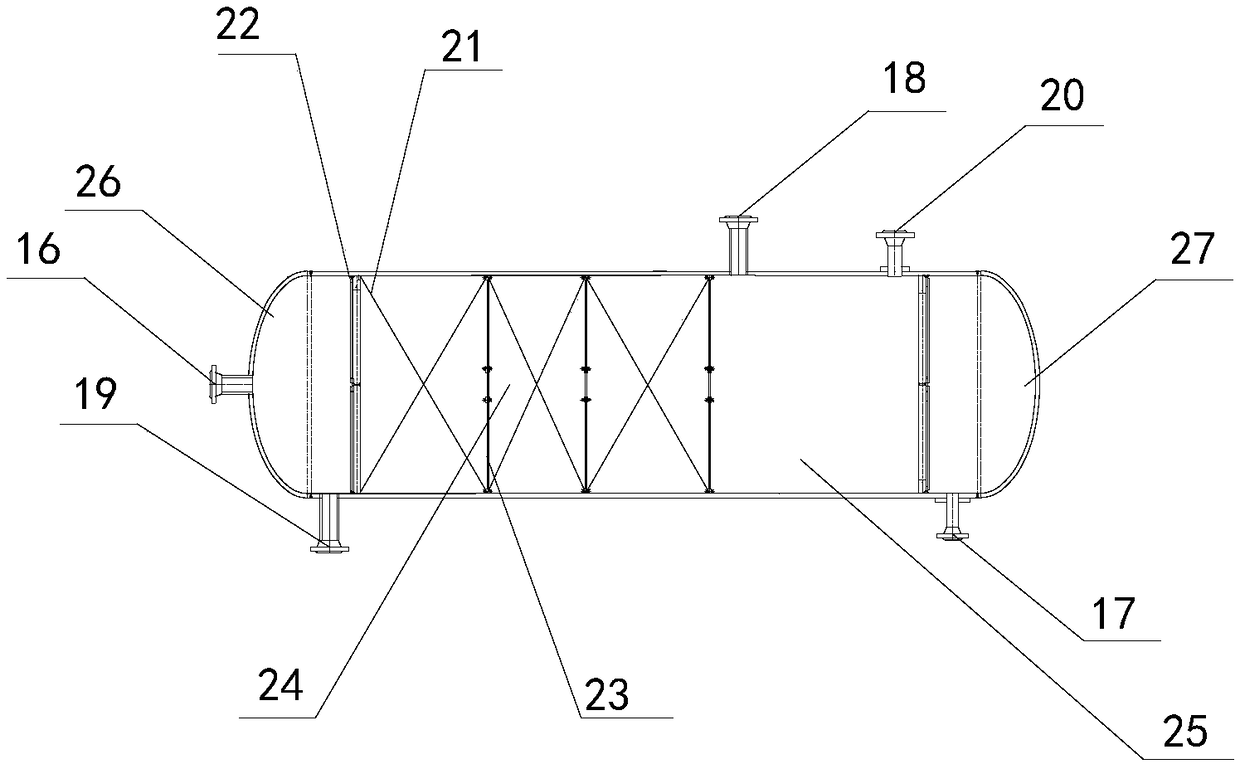

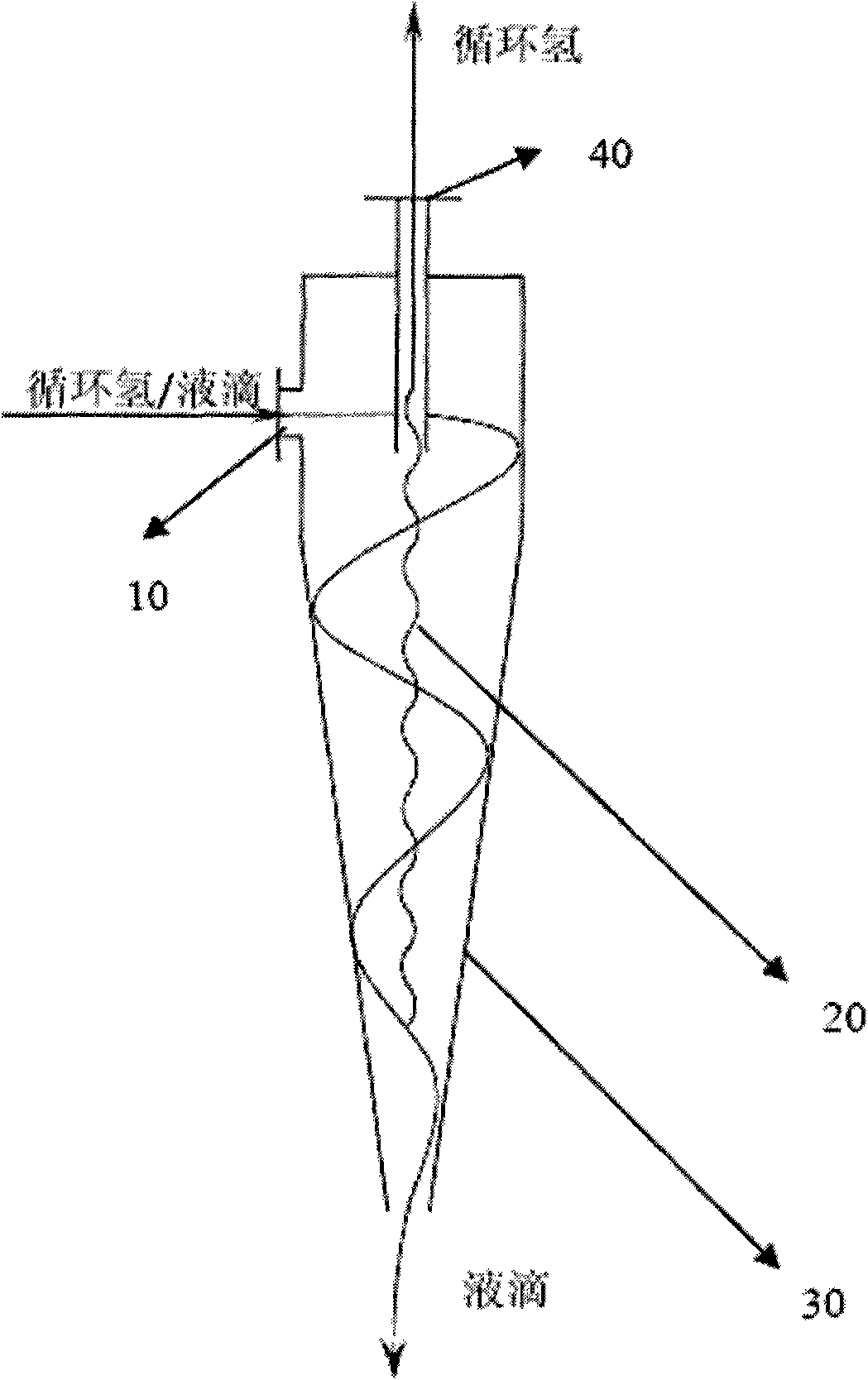

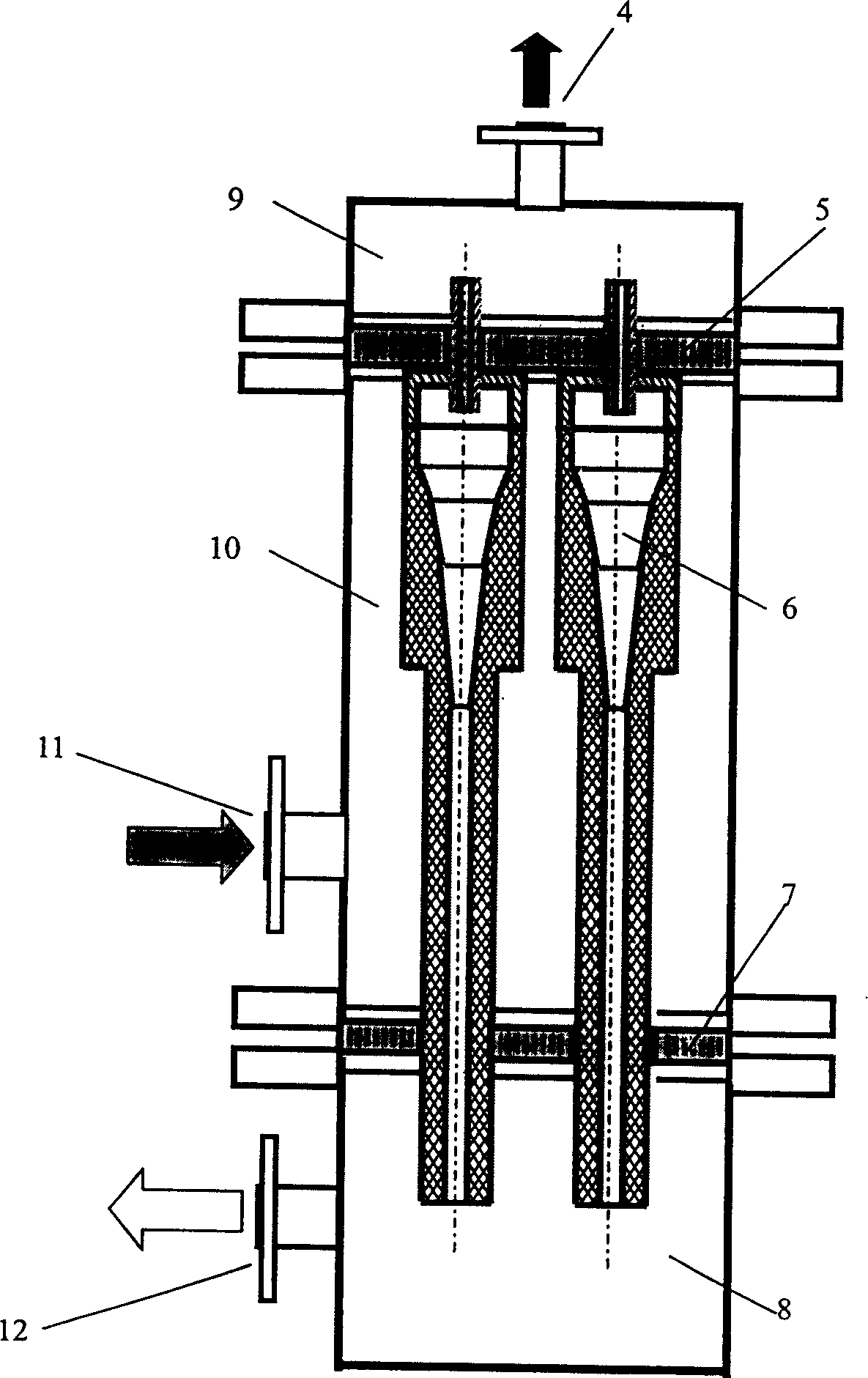

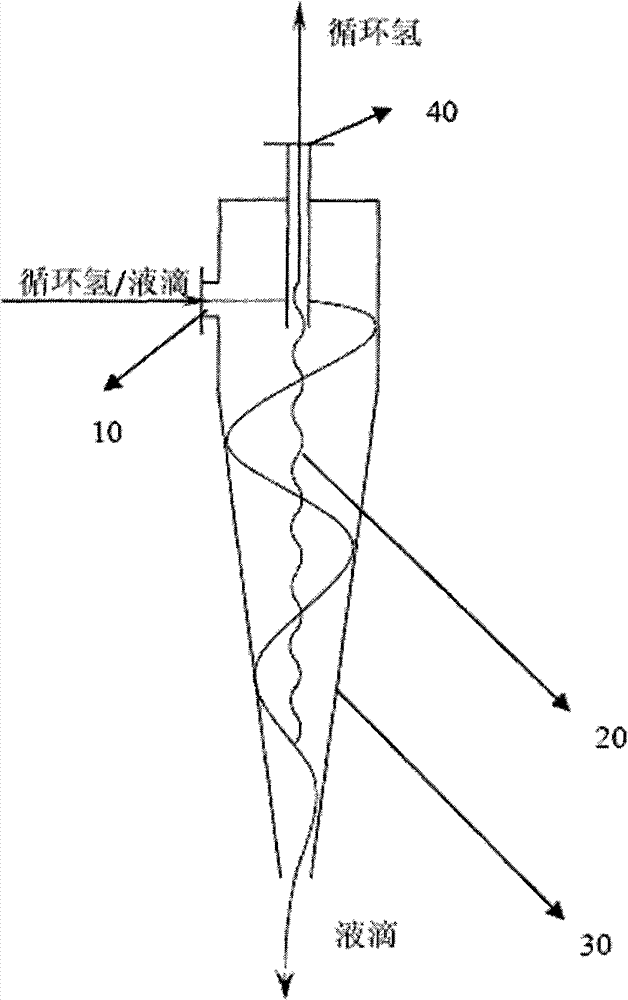

Micro vortex flow tube arrangement method of recycle hydrogen de-hydrocarbon machine

The invention relates to an arranging method of a micro swirl tube used for a cycle-hydrogen hydrocarbon remover and a corresponding apparatus, and provides an arranging method of the micro swirl tube used for the cycle-hydrogen hydrocarbon remover. The method includes the following steps: the inlets of the micro swirl tube of the micro tube units in the cycle-hydrogen hydrocarbon remover are collected and are connected in a sealed manner with the inlet of a pressure container of the recycle-hydrogen hydrocarbon remover. The invention also provides a cycle-hydrogen hydrocarbon remover apparatus.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Coking emptying tower oily wastewater treatment device and method

InactiveCN109081479AReasonable designEasy to operateFatty/oily/floating substances removal devicesSpecific water treatment objectivesRaw waterSewage treatment

The invention relates to the technical field of oily wastewater purification treatment and recycling comprehensive utilization and provides a coking emptying tower oily wastewater treatment device andmethod. The device comprises a raw water storage tank, a coalescer, a membrane separator, a microelectrolysis reactor and a settling tank. The raw water storage tank is used for storage of coking emptying tower oily wastewater, and the wastewater sequentially passes through the coalescer, the membrane separator and the microelectrolysis reactor to finally flow into the settling tank through a rawwater pump; solid-liquid separation is performed in the settling tank to obtain water according with discharging conditions. By the coking emptying tower oily wastewater treatment device and method,oily wastewater purification treatment and complete collection of recycled oil can be realized; the coking emptying tower oily wastewater subjected to fine deoiling can be recycling as coke cooling water and can also be used after acid steam stripping or discharged into a sewage farm; quality of collected dirty oil is further improved through subsequent treatment to meet the requirement of directrecycling.

Owner:SINOPEC LUOYANG TECH CO LTD +1

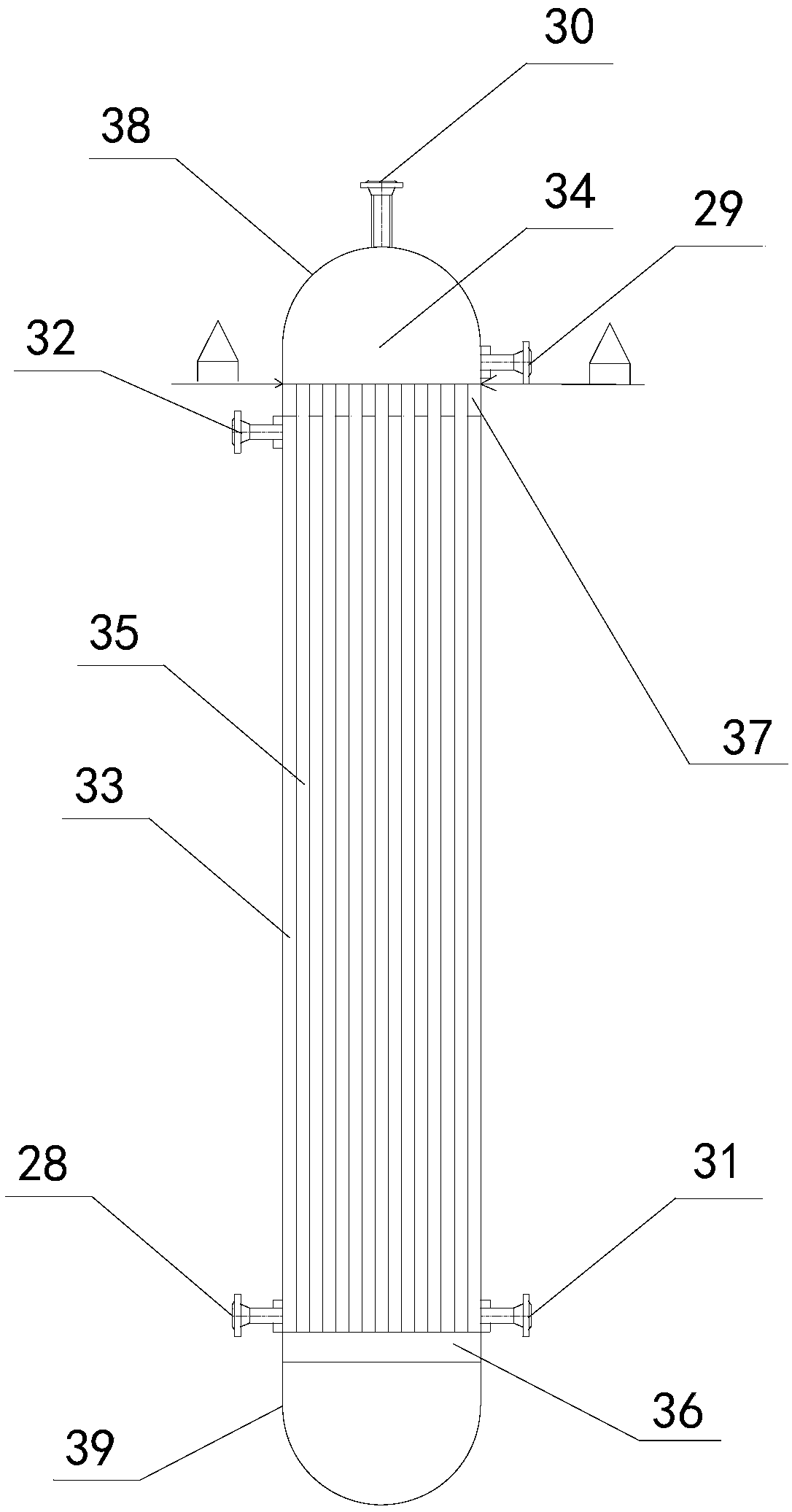

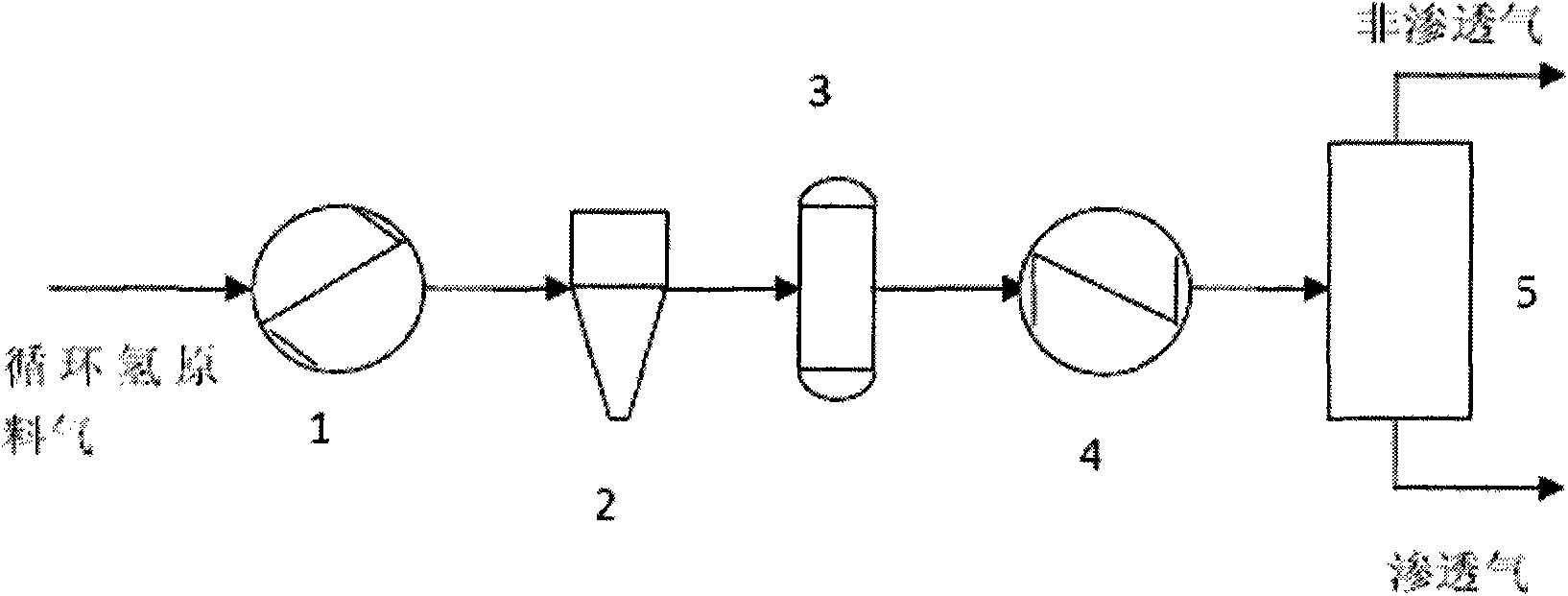

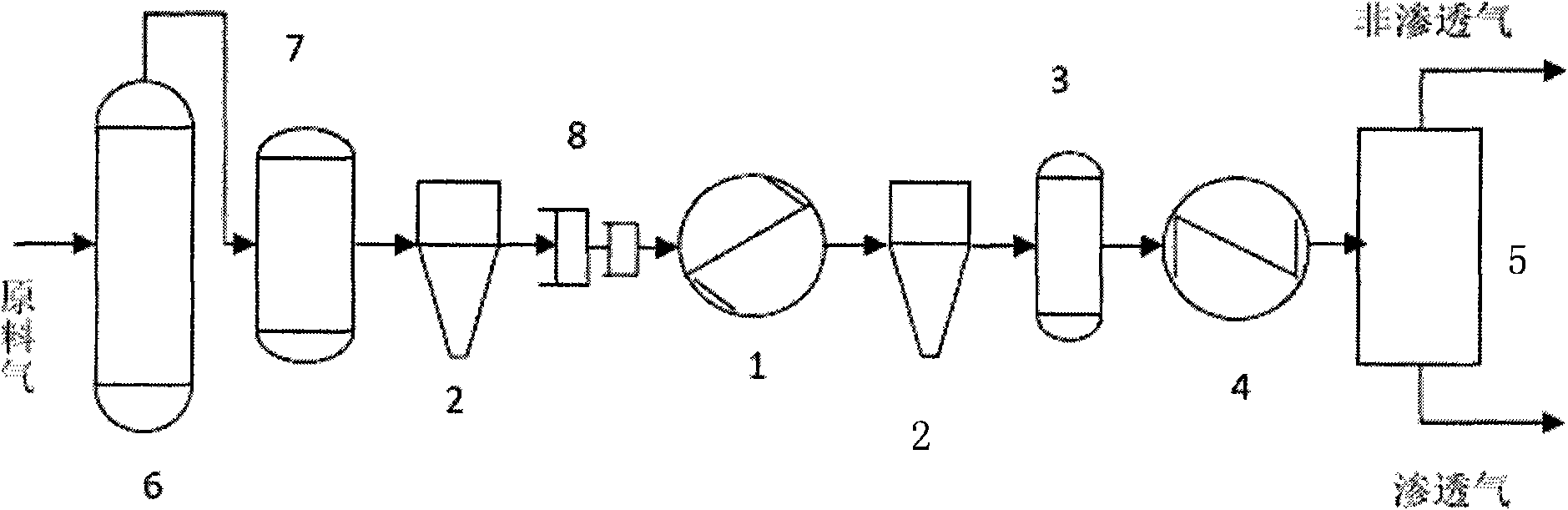

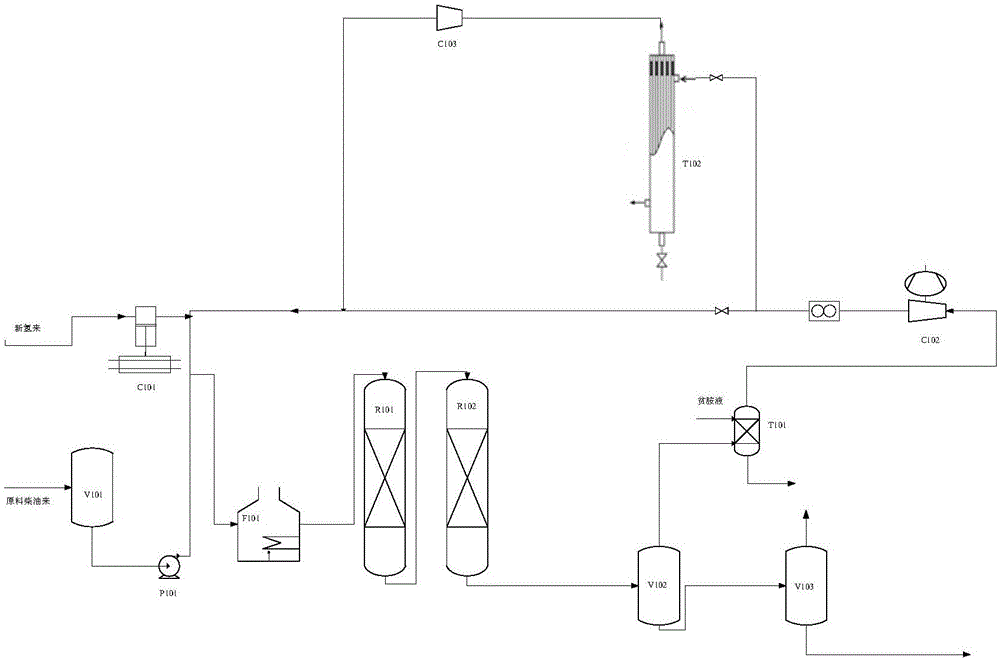

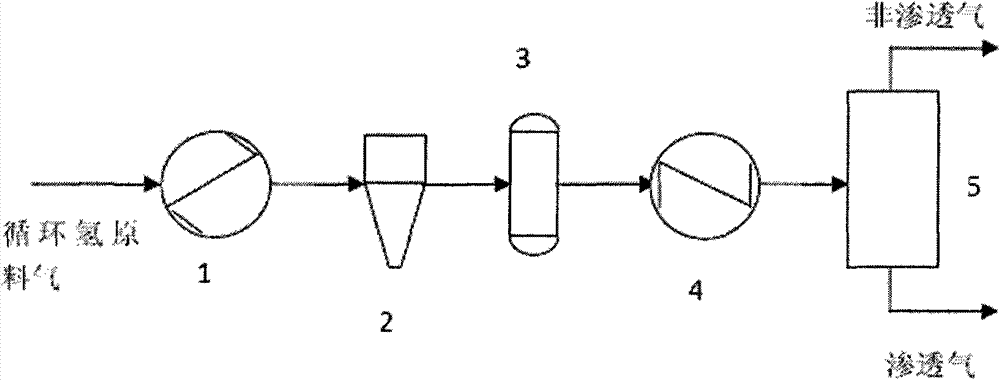

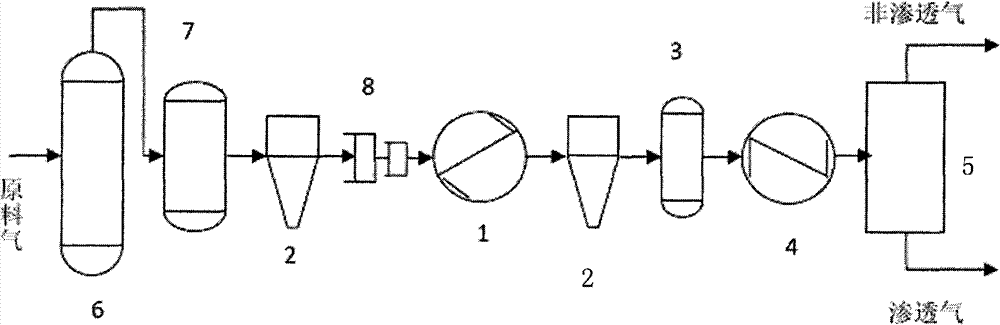

Cyclone-filtering-membrane combined recycle hydrogen purifying method and device

ActiveCN101935019AReduce contentSimple structureCombination devicesHydrogen separationHydrogenImpurity

The invention relates to a cyclone-filtering-membrane combined recycle hydrogen purifying method and a device, providing the cyclone-filtering- membrane combined recycle hydrogen purifying method. The method comprises the following steps: performing cyclone separation on recycle hydrogen raw material gas to remove drops in the recycle hydrogen; filtering the recycle hydrogen raw material gas subject to cyclone separation to further remove fine drops in the recycle hydrogen; and performing membrane separation on the filtered recycle hydrogen raw material gas to remove impure gases in the recycle hydrogen so as to obtain concentrated hydrogen. The invention also provides the cyclone-filtering-membrane combined recycle hydrogen purifying device.

Owner:EAST CHINA UNIV OF SCI & TECH

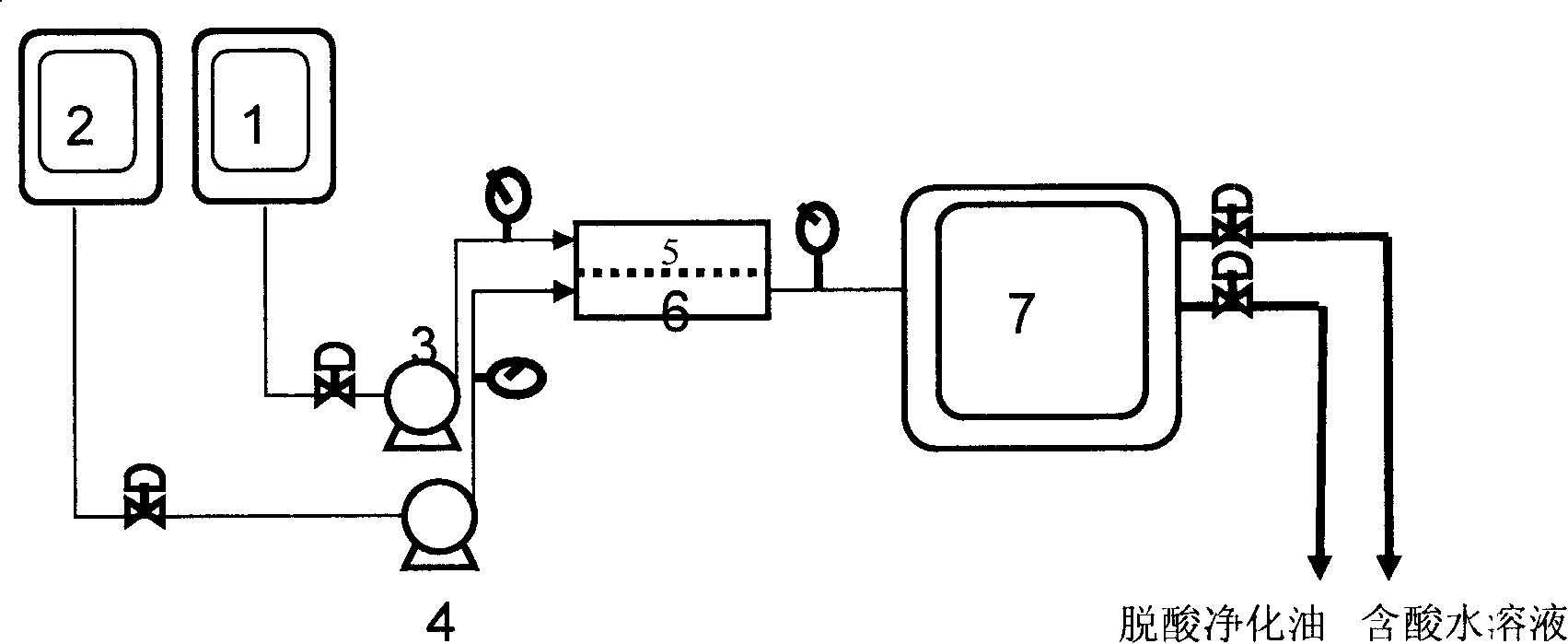

Method for removing petroleum acid in hydrocarbon oil by using membrane dispersion extractor

InactiveCN101200653ASmall amount of lye entrainmentLow lye entrainmentRefining by dialysisSolventChemistry

The present invention relates to a method of removing petroleum acid from hydrocarbon oil by a membrane dispersion extraction device. A continuous phase of the hydrocarbon oil is heated up to 10 DEG C to 150 DEG C; deacidification solvent dispersed phase is heated up to 10 DEG C to 90 DEG C; the cubage ratio of the continuous phase and the dispersed phase is 50 to 2 ®U 1; the pressure difference of the dispersed phase and the continuous phase is 0.05MPa to 0.4MPa; the flow velocity of the dispersed phase deacidification solvent is 0.5 to 5L / <2> per hour; membrane aperture is 0.01 to 60 microns; the dispersed phase deacidification solvent is dispersed into continuous phase oil through membrane micropores; clean oil after the deacidification is obtained after sedimentation and separation. The deacidification solvent is 1 percent to 15 percent of ammonia, 20 percent to 70 percent of alcohol or 0.02 percent to 5 percent of petroleum acid or 0.004 percent to 1 percent of demulsifier and the water with the rest quantity. The contacting time of the oil and the solvent is short; mass transfer efficiency is high; the disposal capability is large; the extraction course is not emulsified easily; the hydrocarbon oil contains little alkali liquid; the device operation is convenient.

Owner:PETROCHINA CO LTD +1

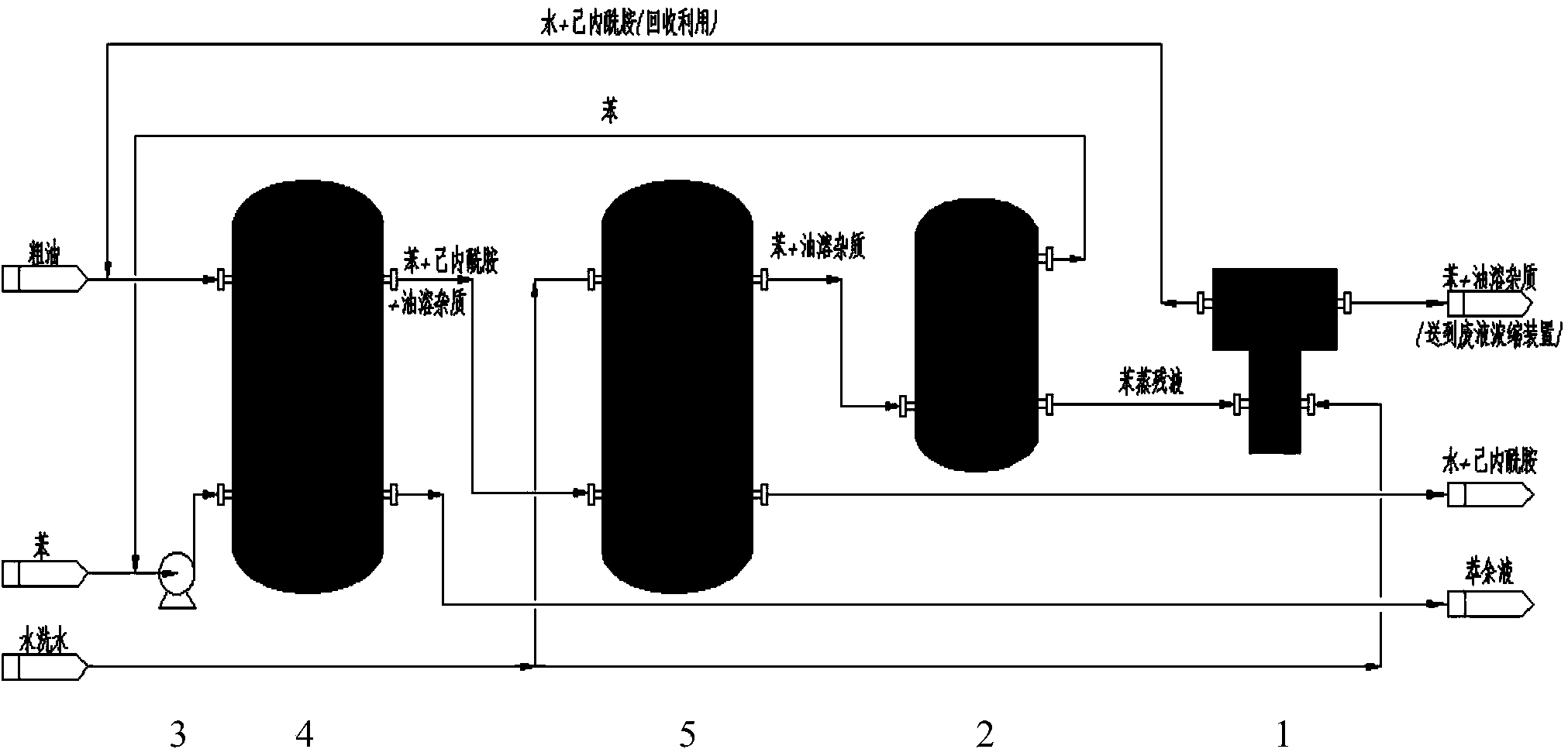

Method and device for recycling caprolactam in benzene distillation residual liquid

ActiveCN104326982ASolving Recycling ProblemsReduce loadLactams separation/purificationLiquid solutions solvent extractionBenzeneDistillation

The invention relates to a method and device for recovering caprolactam in benzene distillation residue, and provides a method for recovering caprolactam in the benzene distillation residue. The method comprises the following steps: (a) respectively feeding the benzene distillation residue and water obtained by distilling in a benzene distillation column into a centrifugal extractor; (b) enabling the benzene distillation residue and water to fully mix and be subjected to mass transfer in the centrifugal extractor, in order to extract caprolactam in benzene distillation residue into the water; (c) performing liquid-liquid separation on the mixed solution of the benzene distillation residue and water through the centrifugal extractor in order to separate out an aqueous solution rich in caprolactam and the benzene distillation residue in which the caprolactam is removed; and (d) recycling the aqueous solution rich in caprolactam, separated out in step (c), and treating the benzene distillation residue in which the caprolactam is removed, by incineration. The invention also provides the device for recovering the caprolactam in the benzene distillation residue.

Owner:EAST CHINA UNIV OF SCI & TECH

A method for reducing a sodium salt content of an alkaline-solution-containing crude alcohol ketone material

ActiveCN107540523AAchieve primary separationEfficient removalOrganic compound preparationHydroxy compound separation/purificationAlcoholKetone

The invention discloses a method for reducing a sodium salt content of an alkaline-solution-containing crude alcohol ketone material. According to the method, a desalting device is utilized to desaltthe crude alcohol ketone material. The desalting device includes a mixing tank, a two-phase separator and a salt extraction column which are connected in order through pipelines. After the crude alcohol ketone material is fully mixed in the mixing tank, the crude alcohol ketone material is pumped into the two-phase separator to allow an alcohol ketone organic phase and an alkaline solution aqueousphase to be separated, the alkaline solution aqueous phase is discharged from the bottom of the two-phase separator, the alcohol ketone organic phase is fed into the lower part of the salt extractioncolumn from the top of the two-phase separator, and is brought into countercurrent contact with process water entering the salt extraction column from the upper part of the salt extraction column toachieve water washing, an obtained alcohol ketone material is discharged from the top of the salt extraction column, and a water washing liquid is discharged from the bottom of the salt extraction column. The sodium salt content of the crude alcohol ketone material can be reduced to 10 mg / kg or below by the method, 0.2-2 m<3> / h of the process water can be saved, the water retention volume in equipments is reduced, and energy consumption of equipment is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

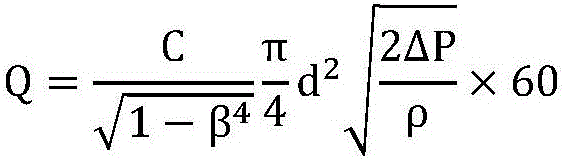

Method and device for denitrifying refinery hydrogen stream

ActiveCN106731527AEasy to separateReduce energy consumptionGas treatmentDispersed particle separationChemistryRefinery

The invention relates to the denitrification of refinery hydrogen streams, and provides a method and a device for denitrifying a refinery hydrogen stream. The method comprises the steps: not carrying out denitrifying treatment on the stream when the nitrogen content of the hydrogen stream is relatively low; feeding the nitrogen-containing hydrogen stream into the denitrifying device for denitrifying treatment when the nitrogen content of the hydrogen stream reaches a certain value, wherein the hydrogen stream requires to be fed to a compressor for pressurization after denitrification due to pressure drop caused during the denitrification. The nitrogen content is subjected to correlated measurement by using a monitoring device, and is used as a criterion for starting denitrifying operation. According to the method and the device, the hydrogen stream comprises a circulating hydrogen stream and a discharge stream of a hydrogen by-production device. The method can be used for optimizing equipment of the existing methods so as to increase the utilization ratio of byproduct hydrogen. The invention further provides the hydrogen stream denitrifying device.

Owner:ZHEJIANG UNIV

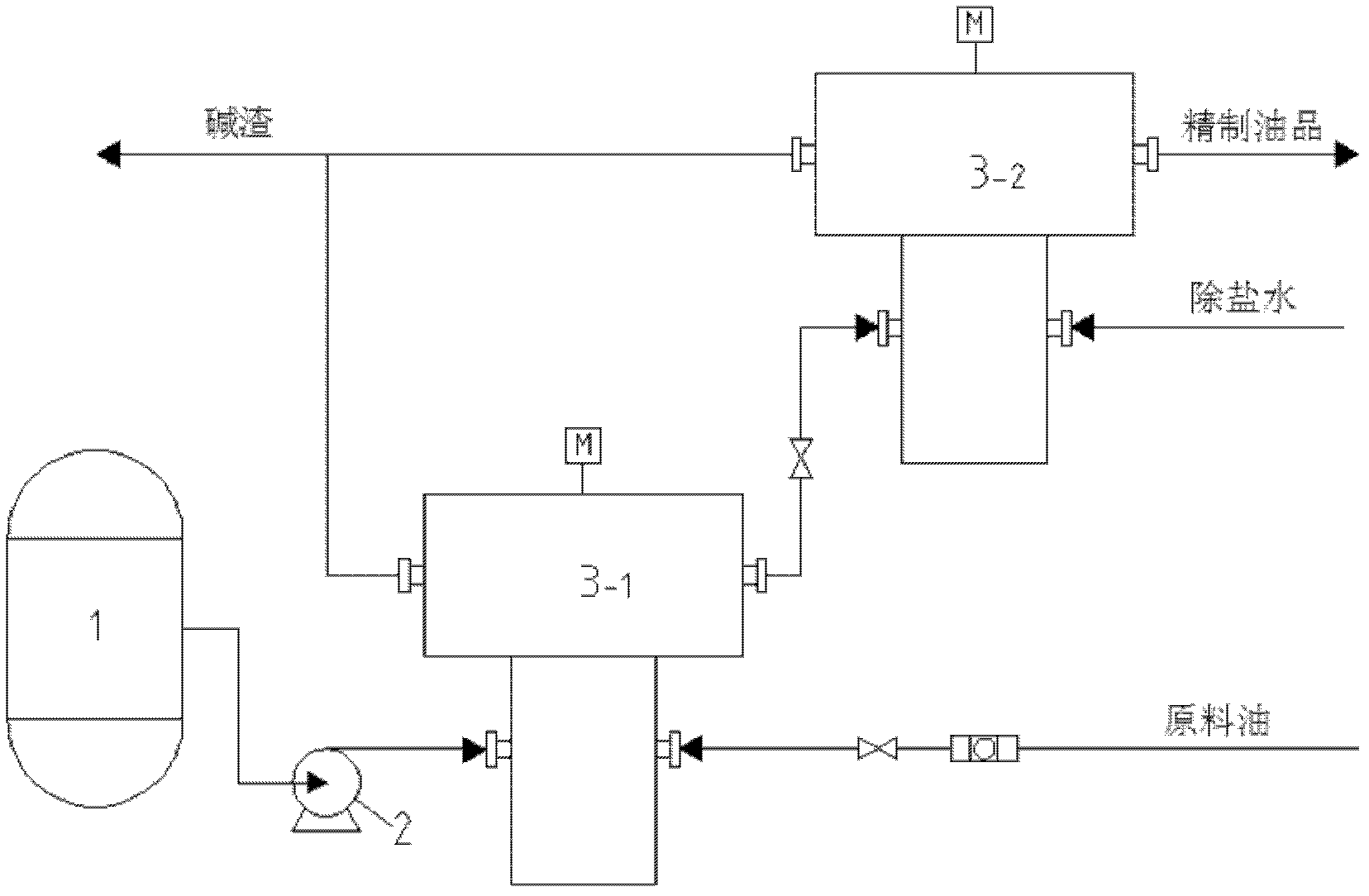

Straight-run diesel oil deacidification method and device for achieving same

InactiveCN102304385AReduce usageOvercome the shortcomings of incomplete separationTreatment with plural serial refining stagesSlagPetrochemical

The invention provides a novel straight-run diesel oil deacidification method. The method comprises the step of carrying out extraction separation on diesel oil in an alkali washing and deacidification process by utilizing a centrifugal extraction separator so that the acidity of the diesel oil is less than 1.5mg / (100ml), and the mass fraction of oil in alkali slag is less than 2%. The invention also provides a straight-run diesel oil deacidification device. By the method and device provided by the invention, the separation efficiencies of alkali washing and water washing in the diesel oil deacidification process are improved, separation time is reduced, investment is small, and applicability is strong. The method and device provided by the invention are suitable for extraction separation occasions which have the requirements of small two-phase density difference, large viscosity, short separation time and the like in a petrochemical industry.

Owner:EAST CHINA UNIV OF SCI & TECH

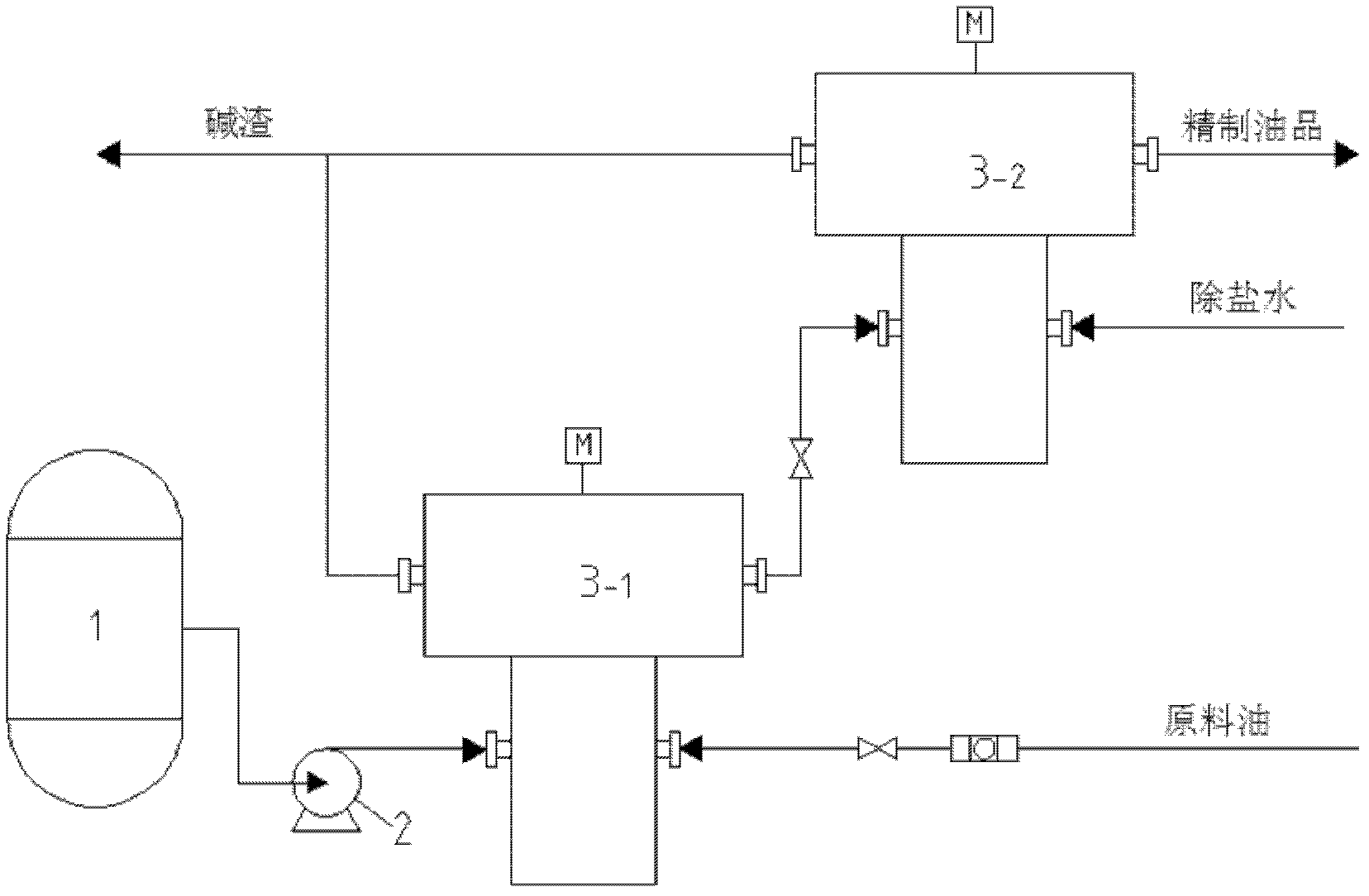

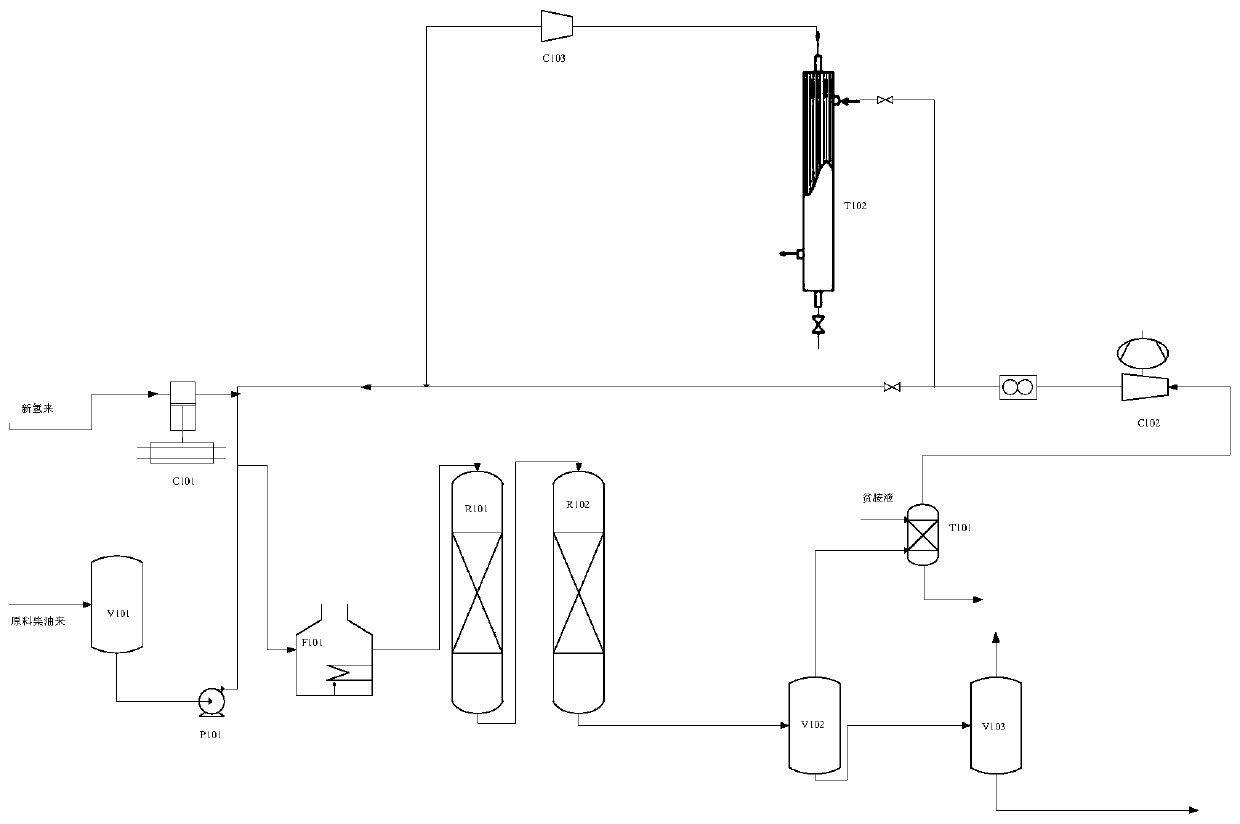

Method and device for hydrocracking mineralized refuse cracked oil

ActiveCN110330996AEasy maintenanceLow running costLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsAlkaneNaphtha

The invention relates to a method and a device for hydrocracking mineralized refuse cracked oil and provides the method for hydrocracking the mineralized refuse cracked oil. The method comprises the following steps: (a) breaking and pyrolyzing mineralized refuse to obtain arene and alkane precursor biomass oil; (b) hydrogenizing the arene and alkane precursor biomass oil obtained in the step (a) and separating an obtained hydrocrackate to obtain arene and alkane; and (c) purifying, recovering and optimizing the arene and the alkane obtained in the step (b), and deeply processing to produce naphtha, jet fuel, light diesel oil and heavy diesel oil. The invention further provides the device for hydrocracking the mineralized refuse cracked oil.

Owner:EAST CHINA UNIV OF SCI & TECH

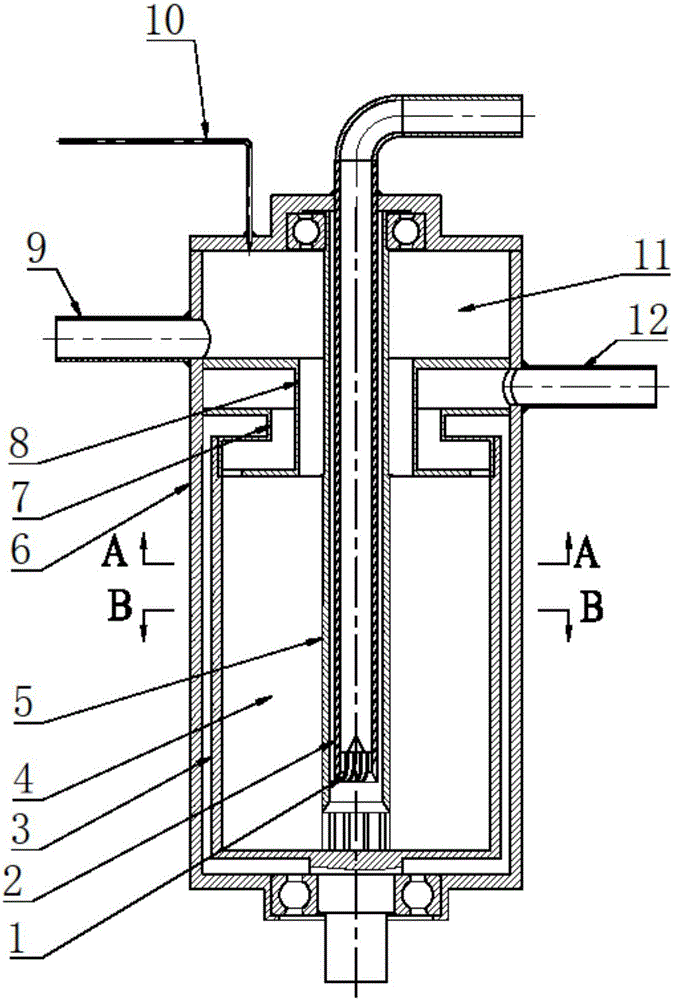

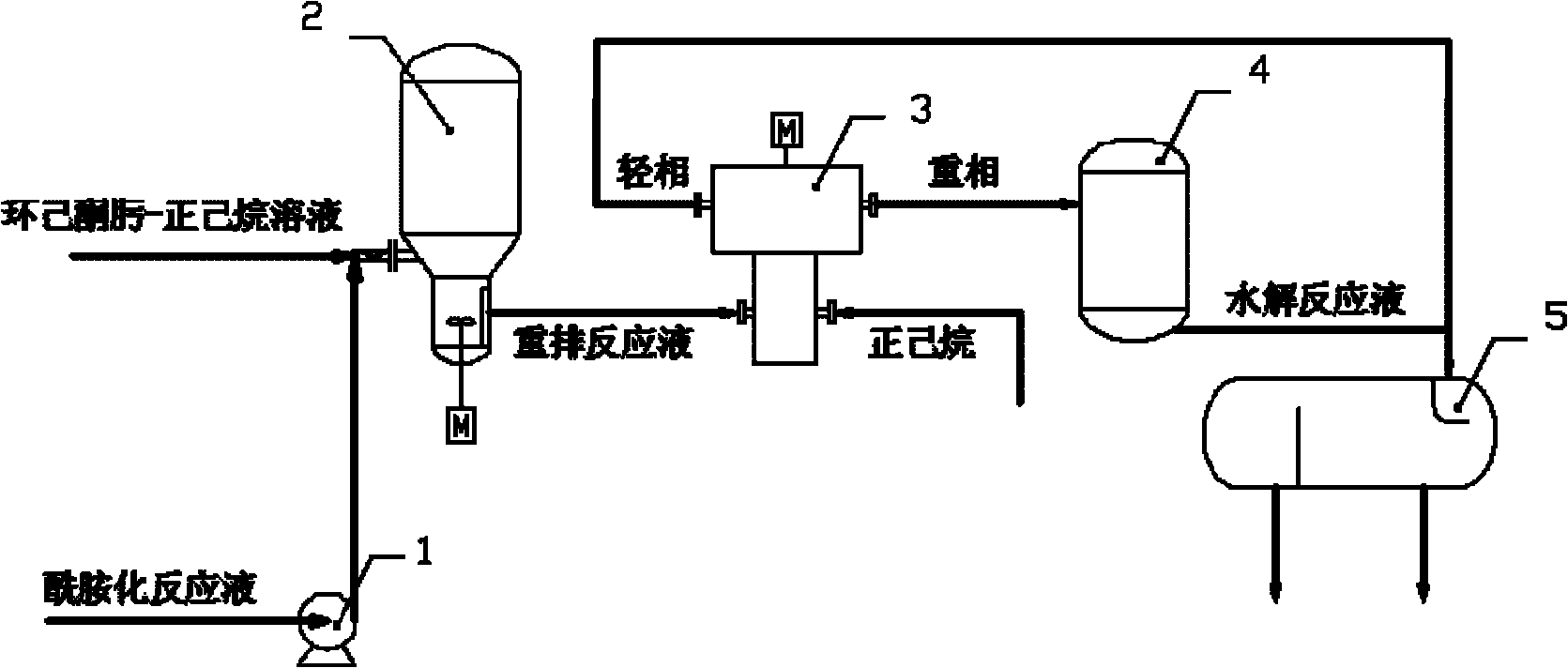

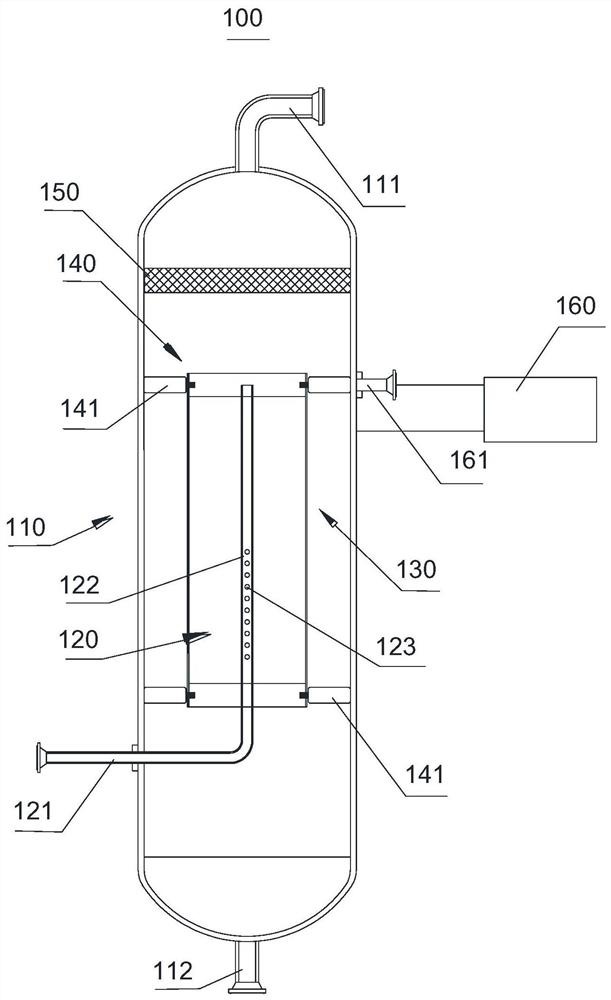

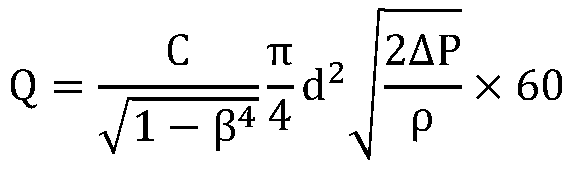

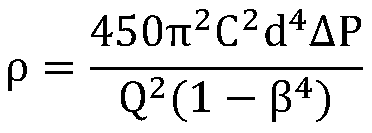

Method and device for extracting hexahydrobenzoic acid from rearrangement reaction liquid

ActiveCN102320958AIncrease productionQuality improvementCarboxylic compound separation/purificationHydrolysisCentrifugal extractor

The invention relates to a method and device for extracting hexahydrobenzoic acid from a rearrangement reaction liquid, and provides the method for extracting hexahydrobenzoic acid from the rearrangement reaction liquid. The method comprises the steps of: (a) conveying the rearrangement reaction liquid from a rearrangement reactor to a heavy phase inlet of a centrifugal extractor, conveying n-hexane to a light phase inlet of the centrifugal extractor, carrying out sufficient mixing and mass transfer on the rearrangement reaction liquid and n-hexane between a high-speed rotating inner drum and a stationary outer drum of the centrifugal extractor, thus extracting hexahydrobenzoic acid from the rearrangement reaction liquid to n-hexane; (b) carrying out liquid-liquid separation on the mixed liquid of the rearrangement reaction liquid and n-hexane with the centrifugal extractor to form a light phase rich in hexahydrobenzoic acid and a heavy phase with hexahydrobenzoic acid removed; and (c) conveying the obtained heavy phase to a hydrolysis reactor for hydrolyzing, then conveying to a sedimentation tank, and directly conveying the obtained light phase to the sedimentation tank. The invention also provides the device for extracting hexahydrobenzoic acid from the rearrangement reaction liquid.

Owner:EAST CHINA UNIV OF SCI & TECH

Deasphalting device and method

ActiveCN113265269AReduced backmixingImprove removal efficiencyRefining by electric/magnetic meansHydrocarbon oils treatmentElectrically conductiveEngineering

The invention relates to the technical field of petroleum processing, and provides a deasphalting device and a method, the deasphalting device comprises a tank body, a feeding distributor, a power line and a conductive hollow cylindrical electrode, the hollow cylindrical electrode is arranged in the tank body, the feeding distributor comprises a discharging section and a conveying section which are connected with each other, the discharging section is located in the hollow cylindrical electrode, the conveying section extends out of the tank body from the lower part of the tank body, a plurality of discharging holes are formed in the discharging section corresponding to the lower part of the hollow cylindrical electrode, the hollow cylindrical electrode is not in contact with the wall surface of the tank body and the feeding distributor, one end of the power line is connected with the hollow cylindrical electrode, and the other end of the power line extends out of the tank body. According to the deasphalting method, the deasphalting device provided by the invention is adopted for deasphalting treatment, and the method and the device have a relatively good effect of removing the asphalt in the raw oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

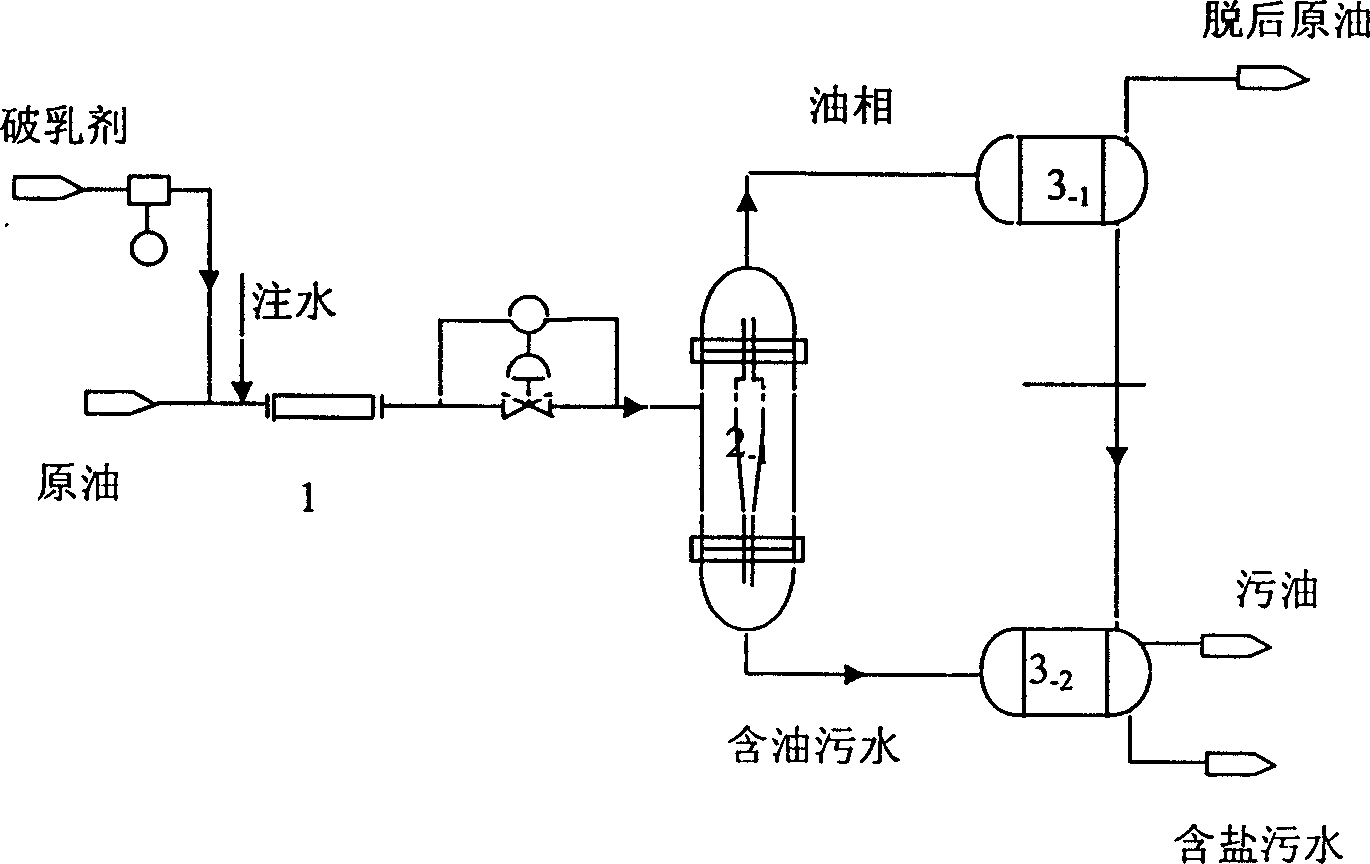

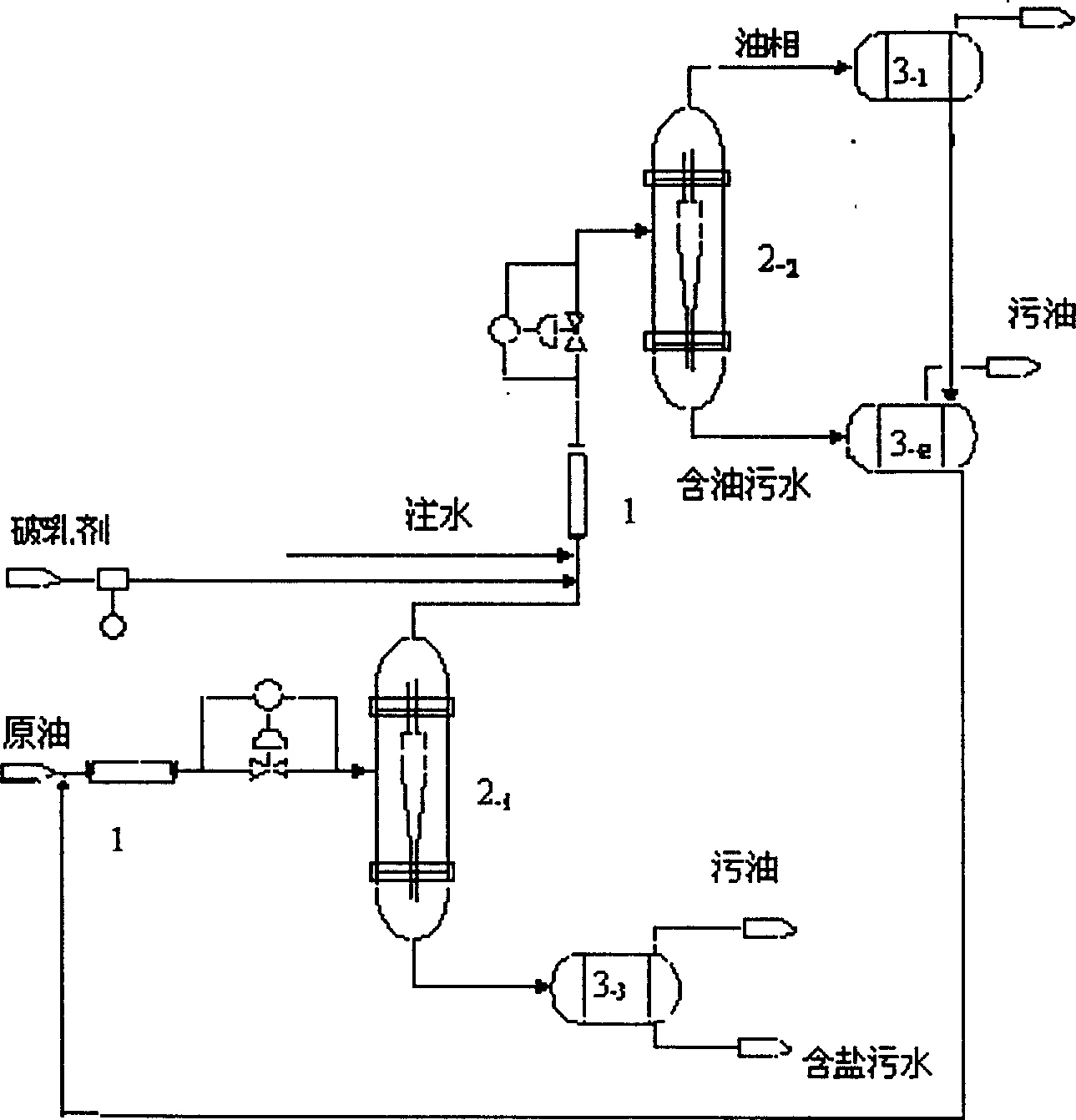

Crude oil desalting method and device using rotational flow breakaway technology

InactiveCN1219856CEasy to operateSimple structureSingle direction vortexRefining by centrifugal forceDemulsifierThermodynamics

The invention relates to a method and device for removing salts in crude oil by using cyclone technology, which is characterized in that crude oil injected with water and demulsifier is separated into oil phase and For oily sewage, the oil phase is settled and separated by the settling tank, and enters the downstream device; the oily sewage is settled and separated into dirty oil and salty sewage by the settling tank, the dirty oil enters the dirty oil tank, and the salty sewage is discharged. One-stage, two-stage or multi-stage cyclone desalting devices can be determined according to the actual salt content of crude oil and the required separation effect. The device can reduce the salt content of crude oil to less than 3mg / L, and the water content in the oil can be reduced to 0.1% (volume ratio), which can replace the traditional thermochemical sedimentation dehydrator and electric dehydrator, and is suitable for popularization and use in the petrochemical industry .

Owner:EAST CHINA UNIV OF SCI & TECH

Cyclone-filtering-membrane combined recycle hydrogen purifying method and device

ActiveCN101935019BReduce contentSimple structureCombination devicesHydrogen separationCycloneHydrogen

The invention relates to a cyclone-filtering-membrane combined recycle hydrogen purifying method and a device, providing the cyclone-filtering- membrane combined recycle hydrogen purifying method. The method comprises the following steps: performing cyclone separation on recycle hydrogen raw material gas to remove drops in the recycle hydrogen; filtering the recycle hydrogen raw material gas subject to cyclone separation to further remove fine drops in the recycle hydrogen; and performing membrane separation on the filtered recycle hydrogen raw material gas to remove impure gases in the recycle hydrogen so as to obtain concentrated hydrogen. The invention also provides the cyclone-filtering-membrane combined recycle hydrogen purifying device.

Owner:EAST CHINA UNIV OF SCI & TECH

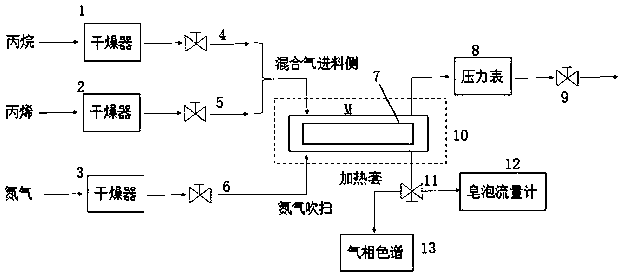

Propane and propylene separation device

PendingCN109482042AEasy to operateReduced maintenance needsComponent separationDispersed particle separationGas phaseEngineering

The invention discloses a propane and propylene separation device, which comprises a first dryer, a second dryer and a third dryer. A first flow control valve is arranged at a downstream position of the first dryer, a second flow control valve is arranged at a downstream position of the second dryer, and a third flow control valve is arranged at a downstream position of the third dryer. Outlets ofthe first flow control valve and the second flow control valve are mixed prior to entering a membrane component, and an outlet of the third flow control valve is connected with the membrane component. A pressure gauge and a pressure regulating valve are arranged at a downstream position of an outlet of the membrane component, a fourth flow control valve is arranged at a downstream position of theother outlet of the membrane component, and the fourth flow control valve is connected with a soap bubble flow meter and a gas chromatograph. The propane and propylene separation device is simple inoperation, low in maintenance demand and suitable for long-period operation, and efficient separation of propane / propylene mixed gas can be realized under a condition of low energy consumption.

Owner:江苏赛瑞迈科新材料有限公司

Method and apparatus for separating cyclo-hexane oxidation waste alkali

ActiveCN100503477CIncrease effective production timeBig investmentWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentLiquid wasteDistillation

Provided are a method and a device for separating spent caustic soda from cyclohexane oxidation liquid by using swirl coalescence series combination technology. By combining the gravity settling tank, the cyclone separator and the coalescence separator to carry out the three-step separation of the spent caustic soda of the cyclohexane oxidation solution, the problem of incomplete separation of the spent caustic solution of the cyclohexane oxidation unit in the prior art can be effectively solved, The invention overcomes the disadvantages of the unsatisfactory effect of the existing gravity sedimentation method and the frequent flushing of the coalescence separation method, greatly prolongs the effective production time of the alkane distillation tower, thereby significantly reducing the production cost.

Owner:EAST CHINA UNIV OF SCI & TECH

A method for reducing sodium salt content in lye-containing crude alcohol and ketone material

ActiveCN107540523BEfficient removalReduce dosageOrganic compound preparationHydroxy compound separation/purificationAlcoholPhysical chemistry

The invention discloses a method for reducing the sodium salt content in crude alcohol and ketone materials containing lye. The method uses a desalination device to desalt the crude alcohol and ketone materials containing lye; the desalination device includes a mixing tank connected by pipelines, a two-phase Separator and salt extraction tower, after the crude alcohol and ketone material containing lye is mixed in the mixing tank, it is pumped into the two-phase separator to separate the organic phase of alcohol and ketone from the water phase of lye; the water phase of lye is separated from the two-phase The bottom of the separator is discharged; the alcohol and ketone organic phase enters the lower part of the salt extraction tower from the top of the two-phase separator, and is countercurrently contacted with the process water entering the upper part of the salt extraction tower for water washing, and the obtained alcohol and ketone material is discharged from the top of the salt extraction tower, and the obtained The washing liquid is discharged from the bottom of the salt extraction tower. This method can reduce the sodium ion content in the lye-containing alcohol and ketone material below 10mg / kg, and save process water by 0.2-2m 3 / h, reduce the stagnation of water in the device, and reduce the energy consumption of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nitrogen removal method and device for refinery hydrogen stream

ActiveCN106731527BEasy to separateReduce energy consumptionGas treatmentDispersed particle separationNitrogen gasRefinery

The invention relates to the denitrification of refinery hydrogen streams, and provides a method and a device for denitrifying a refinery hydrogen stream. The method comprises the steps: not carrying out denitrifying treatment on the stream when the nitrogen content of the hydrogen stream is relatively low; feeding the nitrogen-containing hydrogen stream into the denitrifying device for denitrifying treatment when the nitrogen content of the hydrogen stream reaches a certain value, wherein the hydrogen stream requires to be fed to a compressor for pressurization after denitrification due to pressure drop caused during the denitrification. The nitrogen content is subjected to correlated measurement by using a monitoring device, and is used as a criterion for starting denitrifying operation. According to the method and the device, the hydrogen stream comprises a circulating hydrogen stream and a discharge stream of a hydrogen by-production device. The method can be used for optimizing equipment of the existing methods so as to increase the utilization ratio of byproduct hydrogen. The invention further provides the hydrogen stream denitrifying device.

Owner:ZHEJIANG UNIV

Method and device for extracting hexahydrobenzoic acid from rearrangement reaction liquid

ActiveCN102320958BIncrease productionQuality improvementCarboxylic compound separation/purificationHydrolysisCentrifugal extractor

The invention relates to a method and device for extracting hexahydrobenzoic acid from a rearrangement reaction liquid, and provides the method for extracting hexahydrobenzoic acid from the rearrangement reaction liquid. The method comprises the steps of: (a) conveying the rearrangement reaction liquid from a rearrangement reactor to a heavy phase inlet of a centrifugal extractor, conveying n-hexane to a light phase inlet of the centrifugal extractor, carrying out sufficient mixing and mass transfer on the rearrangement reaction liquid and n-hexane between a high-speed rotating inner drum and a stationary outer drum of the centrifugal extractor, thus extracting hexahydrobenzoic acid from the rearrangement reaction liquid to n-hexane; (b) carrying out liquid-liquid separation on the mixed liquid of the rearrangement reaction liquid and n-hexane with the centrifugal extractor to form a light phase rich in hexahydrobenzoic acid and a heavy phase with hexahydrobenzoic acid removed; and (c) conveying the obtained heavy phase to a hydrolysis reactor for hydrolyzing, then conveying to a sedimentation tank, and directly conveying the obtained light phase to the sedimentation tank. The invention also provides the device for extracting hexahydrobenzoic acid from the rearrangement reaction liquid.

Owner:EAST CHINA UNIV OF SCI & TECH

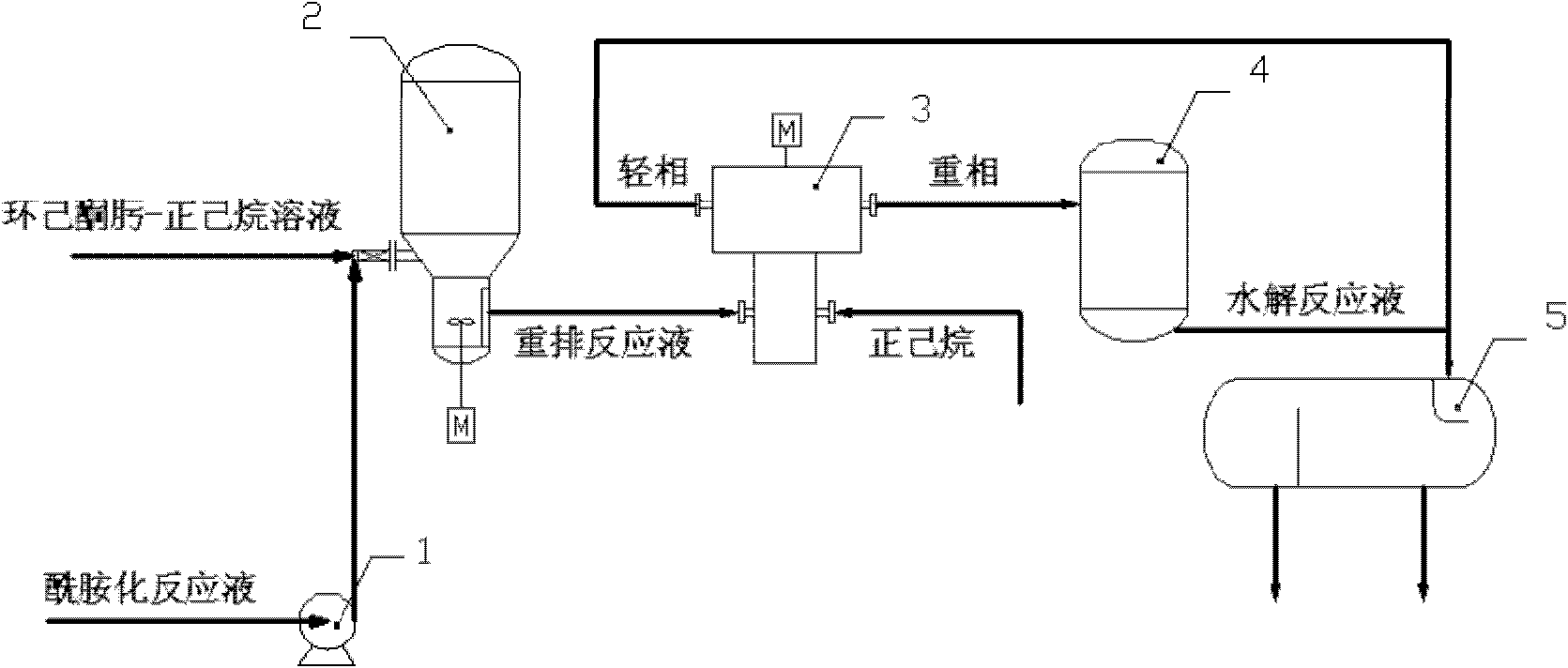

Efficient separation recycling method for solid particles of terephthalic acid oxidized mother liquor

InactiveCN103357205BReduce processing loadLow running costSemi-permeable membranesCentrifugal force sediment separationCycloneDistillation

The invention relates to an efficient separation recycling method for solid particles of terephthalic acid oxidized mother liquor. The method comprises the following steps of: (1) initially separating the terephthalic acid oxidized mother liquor by using a solid-liquid micro-cyclone separator to obtain solid particles with large diameter size; (2) filtering and separating the oxidized mother liquor that is initially separated by the solid-liquid micro-cyclone separator by using a corrosion-resisting efficient metal porous membrane tube; and (3) putting the filtered clear liquid into a distillation column to recycle a solvent, pulping the solid particles in a recycled material storage tank and then putting the pulped solid particles in a material distribution unit for utilization. According to the method disclosed by the invention, the solid and liquid separation efficiency is improved, the post treatment of the oxidized mother liquor in the production process of the terephthalic acid is reduced, efficient recycle of fine solid particles in the oxidized mother liquor can be realized, and the production cost is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of solid vortex centrifugal separation equipment and method for separating oil spill skim

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com