Method and device for absorbing and whirling waste gas

A flow treatment and waste gas technology, applied in the field of waste gas treatment, can solve problems such as detergent loss, impact on surrounding ecosystems, entrainment of hydrophilic gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The present invention is further described below in conjunction with specific examples. However, it should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The test methods for which specific conditions are not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

[0045] Sinopec Baling Branch Chemical Fertilizer Division Urea Plant Exhaust Dust Pollution Prevention and Control Project:

[0046] In order to reduce the ammonia content in the tail gas, the device of the present invention is adopted.

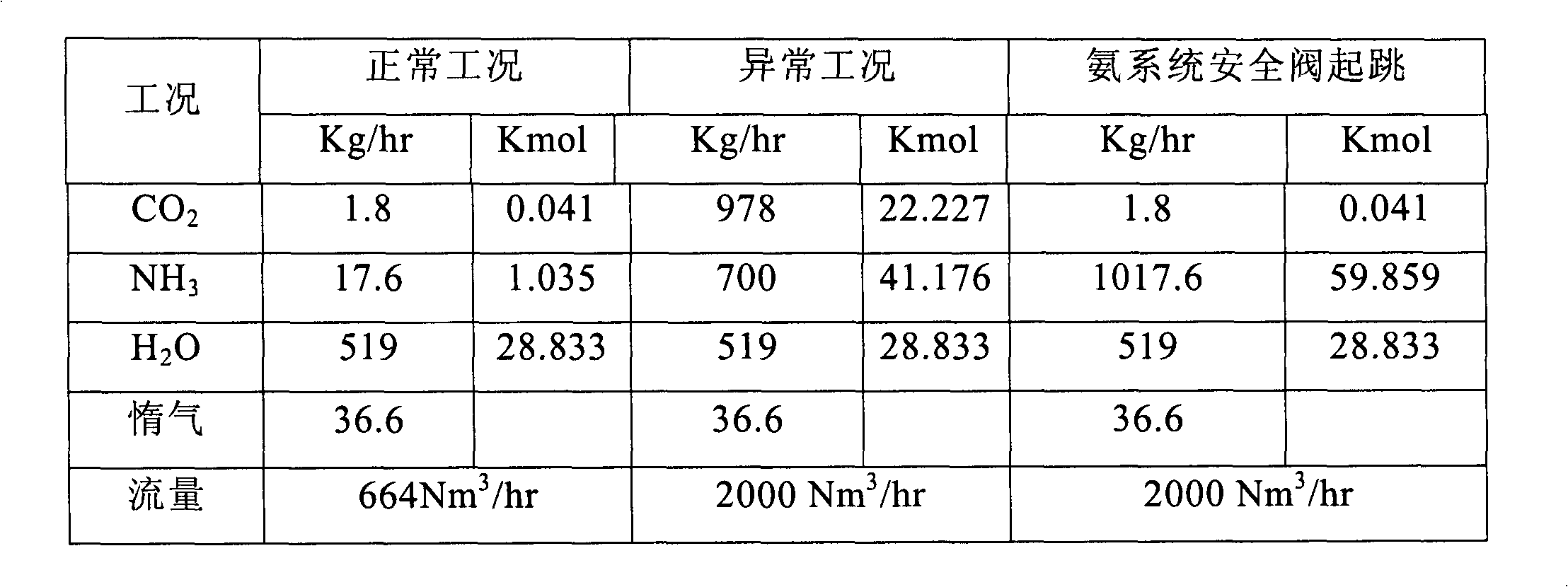

[0047] The following table shows the composition of the exhaust gas:

[0048]

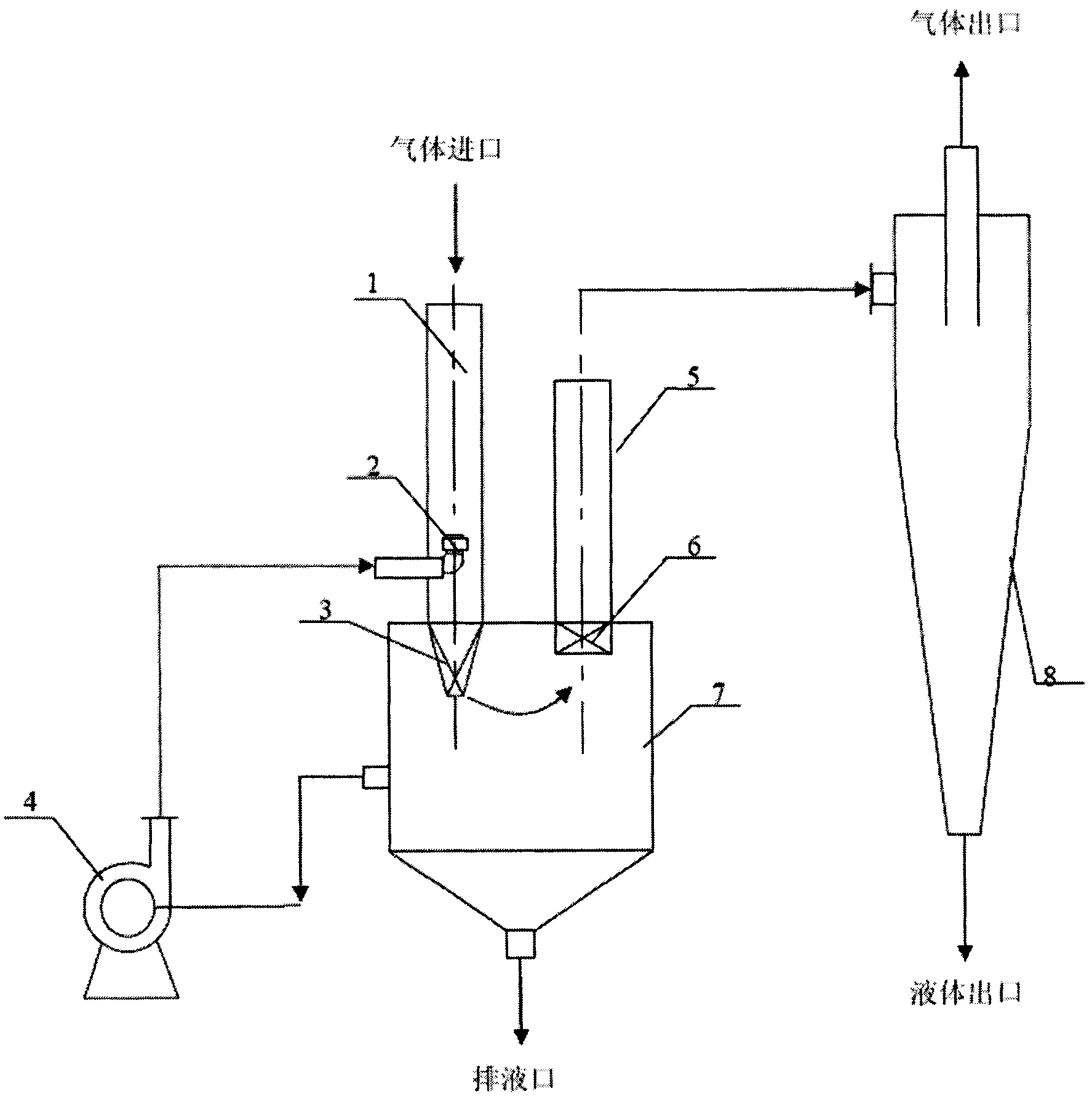

[0049] Specific process such as figure 1 shown.

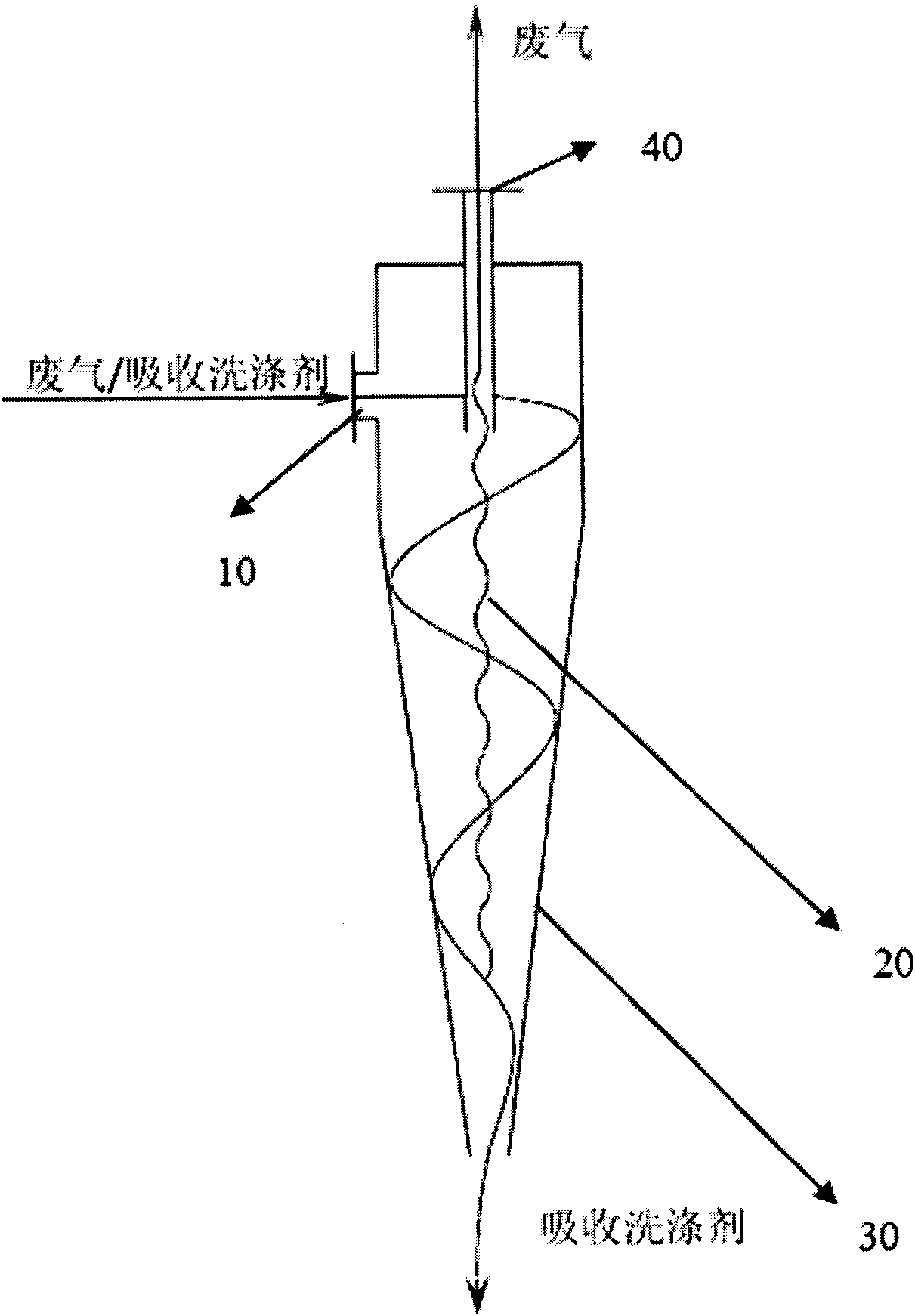

[0050] The impinging foam stream scrubber consists of a scrubber pipe, noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com