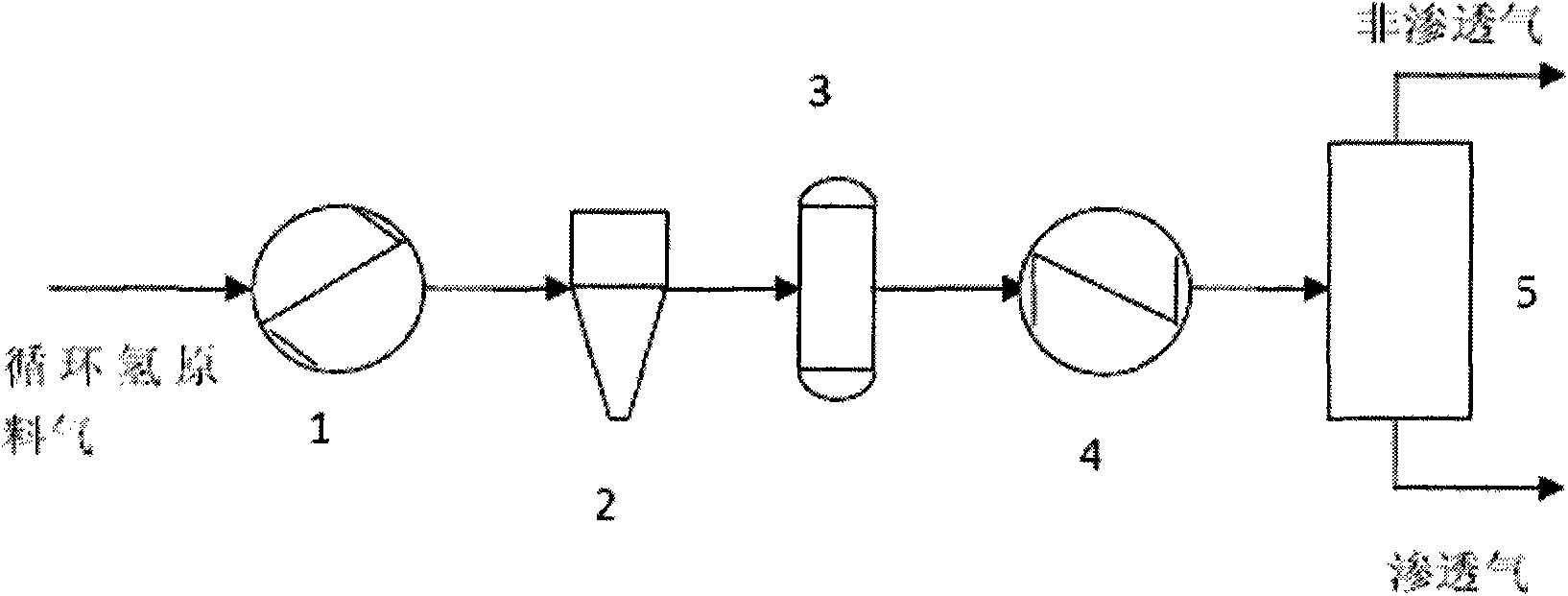

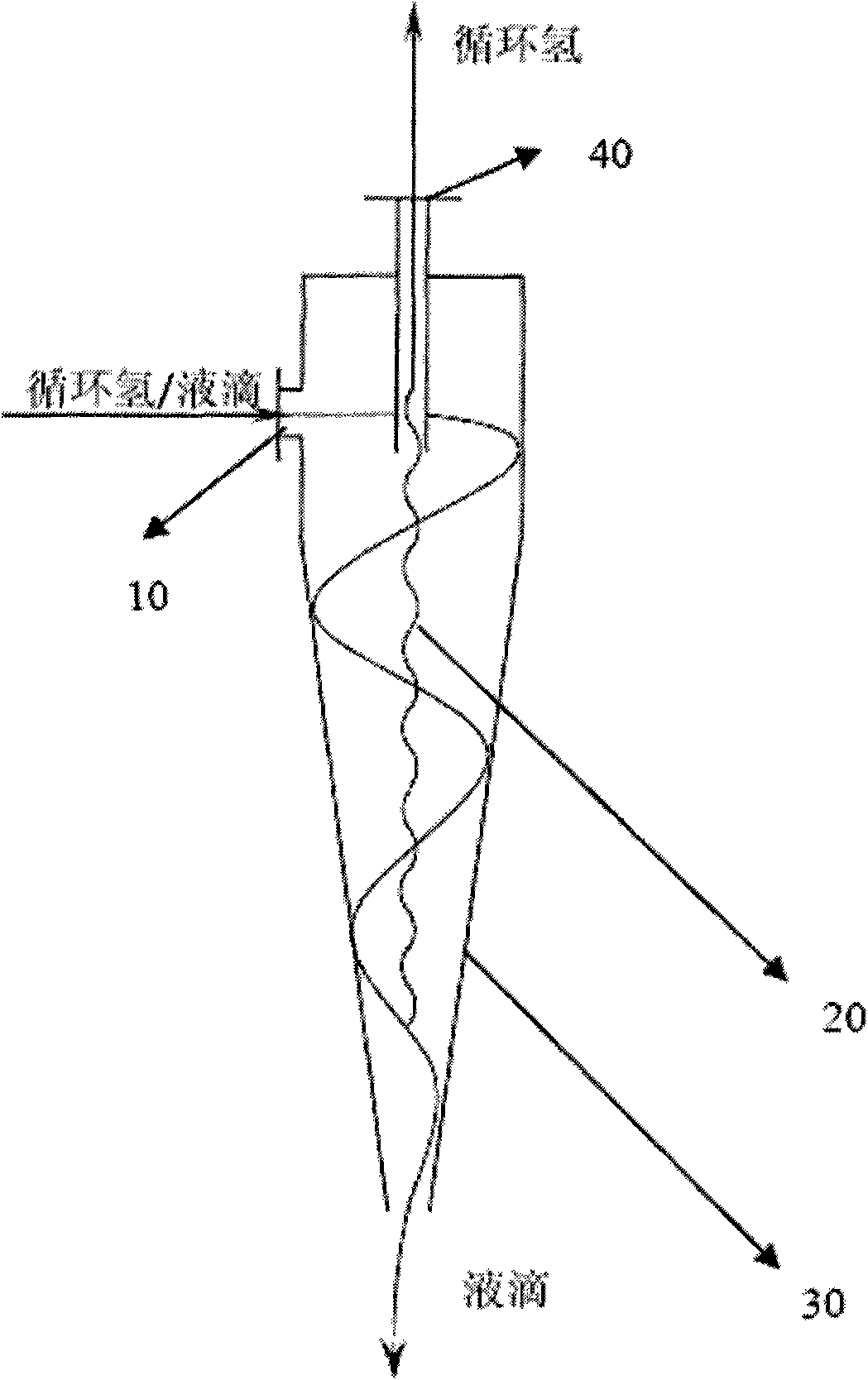

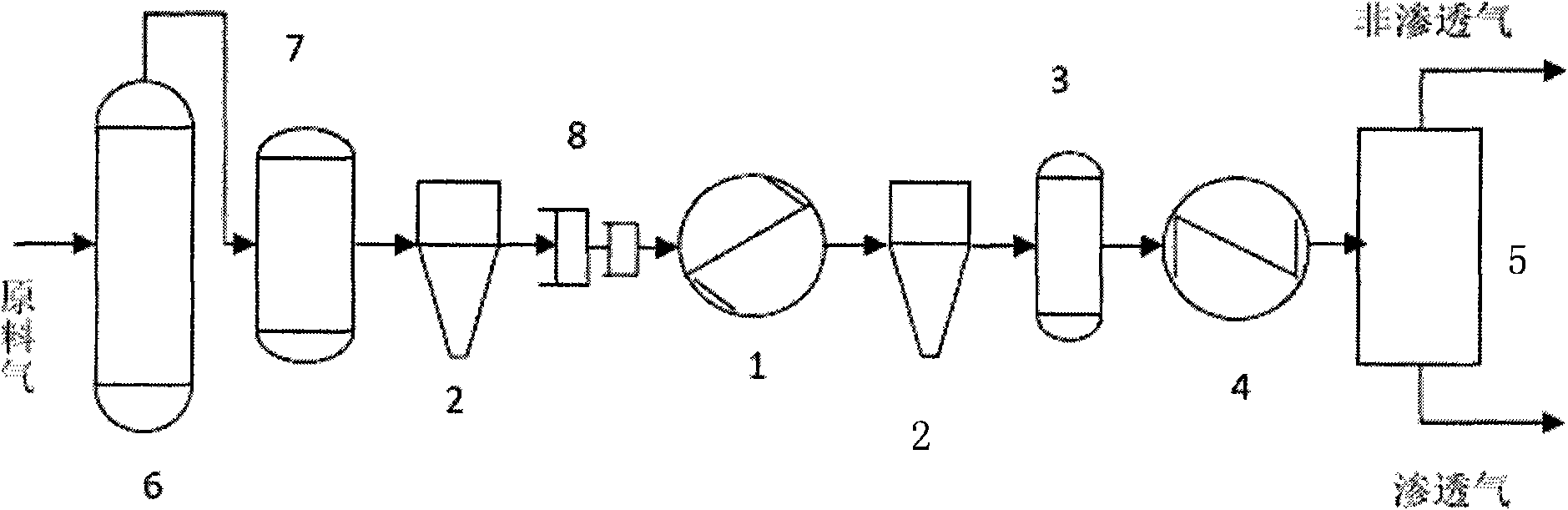

Cyclone-filtering-membrane combined recycle hydrogen purifying method and device

A circulating hydrogen and combined technology, which is applied to the device used to implement the method, in the field of cyclone-filtration-membrane combined circulating hydrogen purification, can solve the problems such as the entrainment of liquid droplets by circulating hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Hydrocracking unit capacity expansion and transformation system of Sinopec Zhenhai Refining and Chemical Company:

[0053] The device of the present invention is adopted in the matching of the system.

[0054] The following table shows the composition of the feed gas:

[0055] project

unit

2009 average

H 2

%(v / v)

67.56

Air

%(v / v)

10.03

%(v / v)

10.65

ethane

%(v / v)

3.80

Vinyl

%(v / v)

0.00

%(v / v)

4.00

Propylene

%(v / v)

0.00

%(v / v)

2.54

n-butane

%(v / v)

1.53

%(v / v)

0.00

Anti-butene

%(v / v)

0.00

[0056] Butene

%(v / v)

0.00

C5

%(v / v)

0.54

CO 2

%(v / v)

0.00

CO

%(v / v)

0.00

C=

%(v / v)

0.00

Comparison method H 2 S

ml / m 3

32.81

...

Embodiment 2

[0061] Example 2: Coal liquefaction unit of Ordos Branch of China Shenhua Coal-to-oil Chemical Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com