Efficient separation recycling method for solid particles of terephthalic acid oxidized mother liquor

A technology of terephthalic acid and solid particles, which is applied in chemical instruments and methods, semi-permeable membrane separation, and sediment separation by centrifugal force, etc., can solve the hidden dangers of increasing the workload of equipment maintenance personnel, high concentration of overflow particles and stable operation. and other problems, to achieve the effect of good corrosion resistance, low operating cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] General idea of the present invention is:

[0033] A method for efficiently separating and recovering solid particles of terephthalic acid oxidation mother liquor, the specific steps are:

[0034] (1) The mother liquor output from the oxidation mother liquor pump enters the solid-liquid cyclone separator, the oxidation mother liquor from the upper end of the micro cyclone separator enters the mother liquor buffer tank, and the solid phase particle concentrate rich in larger particle sizes is separated at the lower end to go Recycled storage tanks;

[0035] (2) The material in the mother liquor buffer tank is pumped into a high-efficiency metal porous membrane tube filter for filtration and separation; under the action of pressure, the mother liquor passes through the filter element, and the filtrate goes to the distillation tower for mother liquor recovery; terephthalic acid or catalyst solid particles are intercepted A filter cake is formed on the outer surface of t...

Embodiment 1

[0043] TA mother liquor filtration

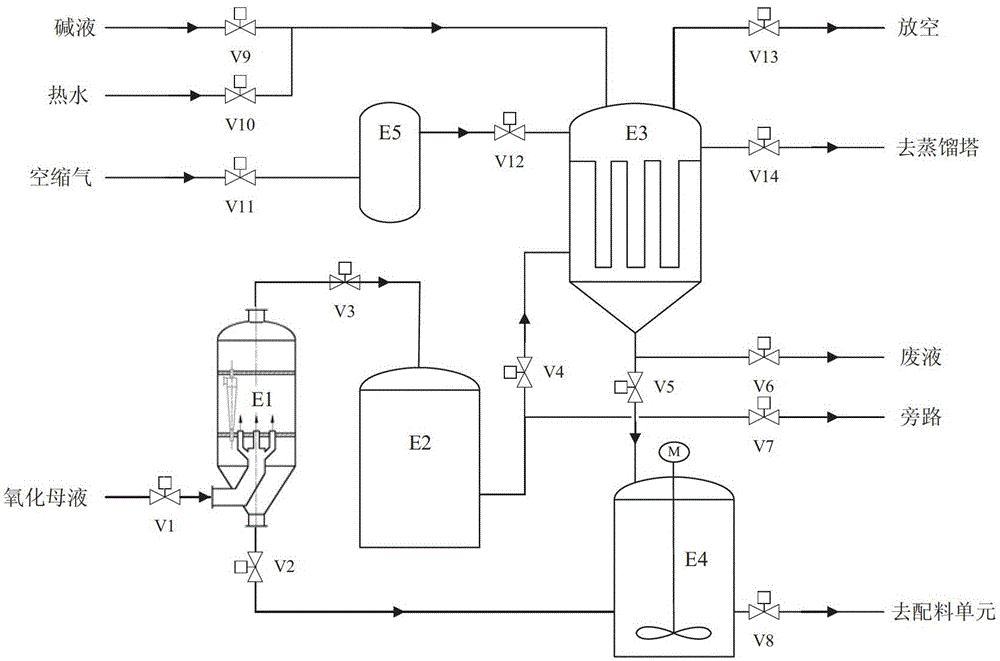

[0044] The TA oxidation mother liquor enters the liquid-solid micro cyclone separator E1 through the control valve V1, the oxidation mother liquor from the upper end of the micro cyclone separator E1 enters the mother liquor buffer tank E2 through the control valve V3, and the solids rich in larger particle sizes are separated at the lower end. The concentrated liquid of phase particles goes to the recovery material storage tank E4 through V2; the mother liquid in the mother liquid buffer tank E2 enters the metal porous material filter E3, and the mother liquid passes through the filter element and the filtrate goes to the distillation tower through the control valve V14 for mother liquid recovery; TA solid particles are retained A filter cake forms on the outer surface of the filter element.

Embodiment 2

[0046] Metal Porous Material Filter Backflush

[0047] When the pressure difference between the inlet and outlet of the metal porous material filter E3 reaches the set value, the filter stops feeding. The backflush nitrogen control valve V12 is opened, and the filtrate in the filter E3 casing flows reversely quickly, pushing the filter cake to leave the filter element and return to the recycled material storage tank E4 through the control valve V5, and the backflush is completed. The material in the recycled material storage tank E4 is sent to the batching unit through the control valve V8 after beating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com