High performance liquid-solution solvent extraction method and device

An extraction and high-efficiency technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of high cost and unsatisfactory extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

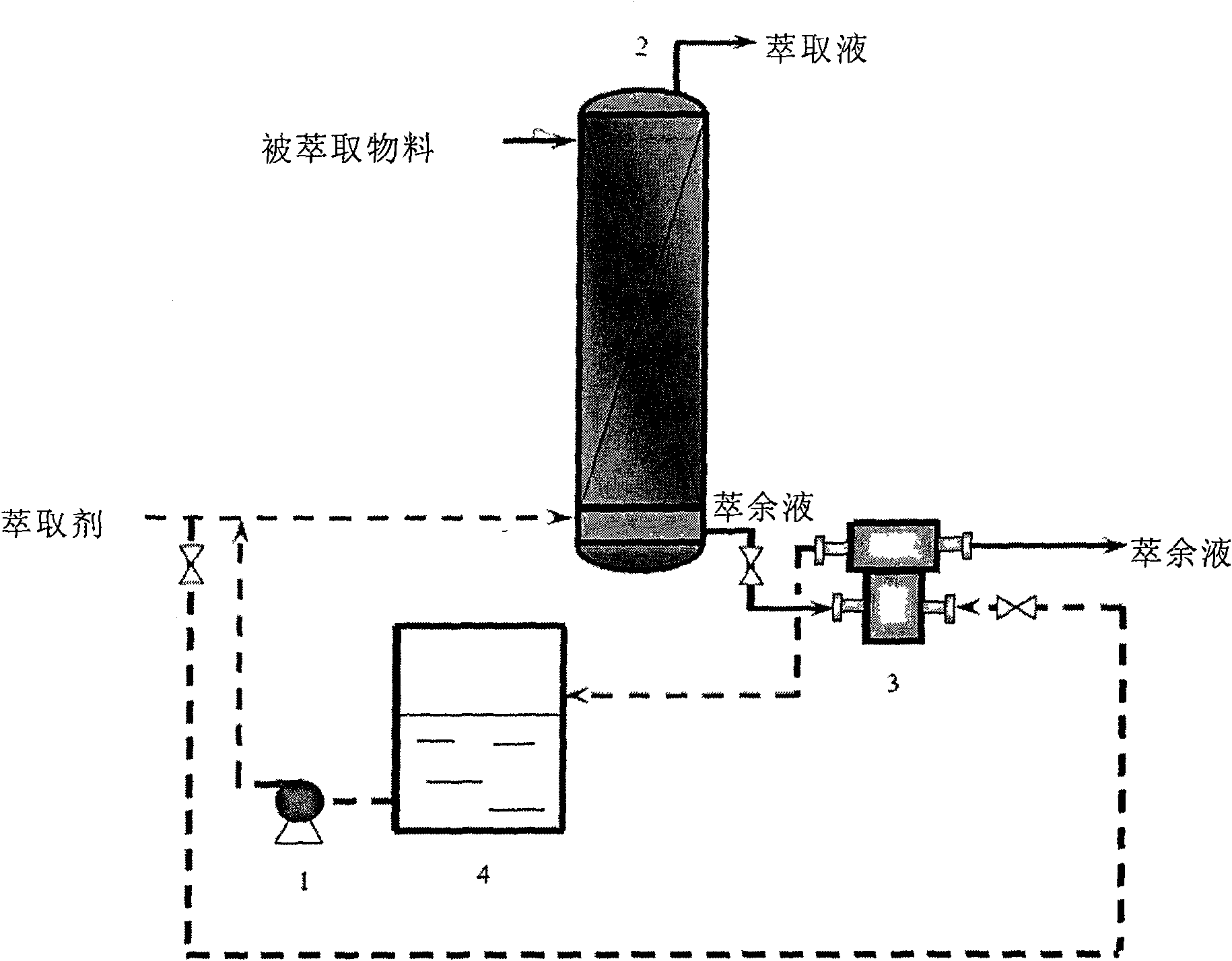

[0042] use figure 1 The shown technological process carries out extraction, specifically as follows:

[0043] 1. Material properties

[0044] (1) Extracted material: the content of caprolactam is 50-60%, the rest is water, and the density of the mixture is 1028kg / m 3 ;

[0045] (2) Extractant: benzene, density is 872kg / m 3 ;

[0046] 2. Determination of caprolactam content

[0047] Caprolactam content is determined by gas chromatography, referring to DSM385-E and 385-02-E and DSM657-E;

[0048] 3. Application effect

[0049] The volume flow ratio of the extracted material and the extractant is 1:6, the content of caprolactam in the extracted material imported from the tower extraction equipment is 50-60%, and the content of caprolactam in the raffinate outlet of the tower extraction equipment is 2-4% , after being extracted by centrifugal extraction equipment, the caprolactam content of the raffinate drops below 1%, which obviously improves the extraction effect.

Embodiment 2

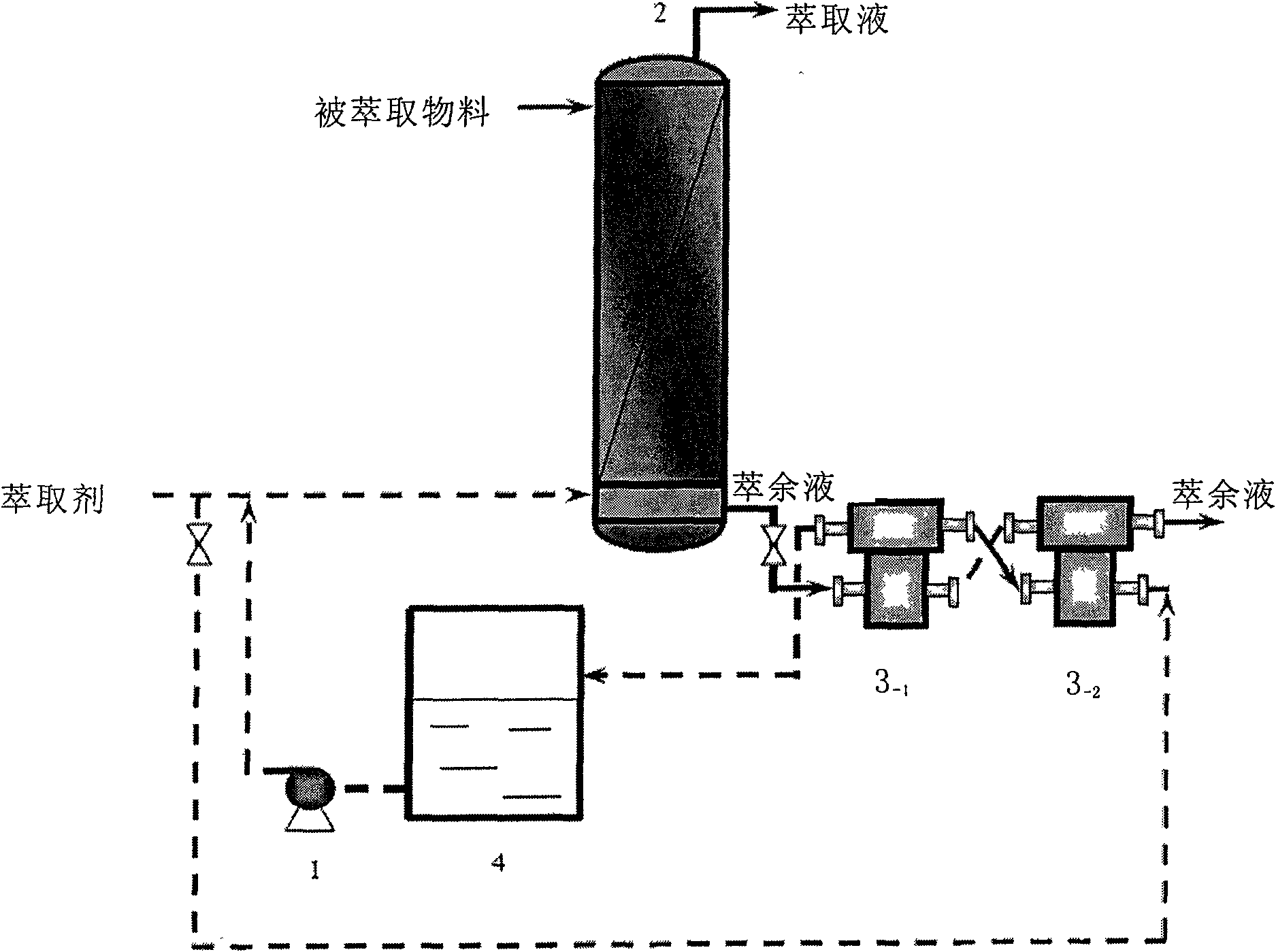

[0051] use figure 2 The shown technological process carries out extraction, specifically as follows:

[0052] 1. Material properties

[0053] (1) Extracted material: the content of caprolactam is 50-60%, the rest is water, and the density of the mixture is 1028kg / m 3 ;

[0054] (2) Extractant: benzene, density is 872kg / m 3 ;

[0055] 2. Determination of caprolactam content

[0056] Caprolactam content is determined by gas chromatography, referring to DSM385-E, 385-02-E and DSM657-E;

[0057] 3. Application effect

[0058] The volume flow ratio of the extracted material and the extractant is 1:6, the content of caprolactam in the extracted material imported from the tower extraction equipment is 50-60%, and the content of caprolactam in the raffinate outlet of the tower extraction equipment is 2-4% , and then extracted by two-stage centrifugal extraction equipment, the caprolactam content of the raffinate drops below 0.3%, which obviously realizes deep extraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com