Method and device for desulphurization of recycle hydrogen

A technology of circulating hydrogen and desulfurization tower is applied in the field of compact circulating hydrogen desulfurization, which can solve the problems of amine liquid running loss and foaming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: 2.2 million tons / year hydrocracking treatment unit

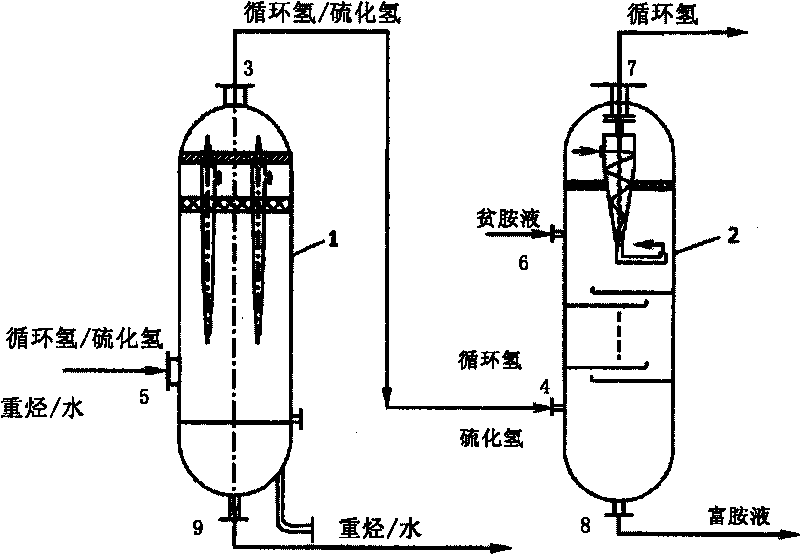

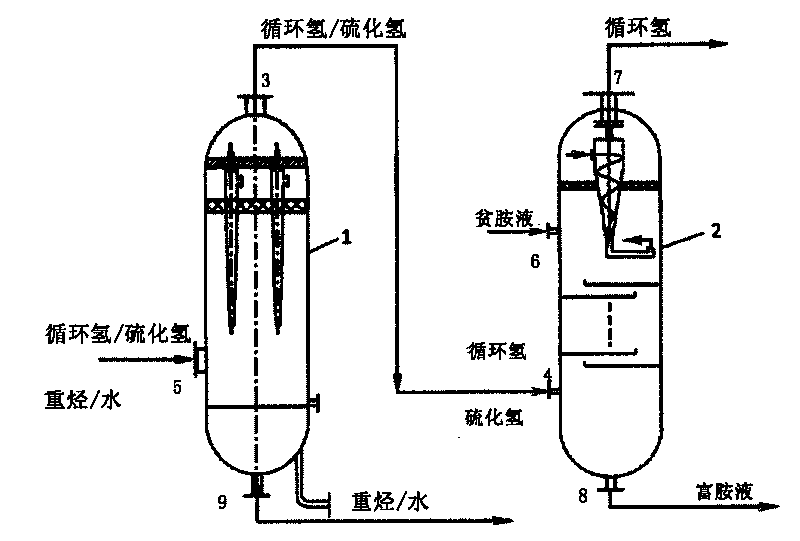

[0059] In a hydrocracking treatment unit with an annual processing capacity of 2.2 million tons / year, a set such as figure 1 The cyclone-enhanced high-pressure separator shown is directly connected to the circulating hydrogen desulfurization tower, and its specific operation process and effect are described as follows:

[0060] When the hydrogenation process is started, the circulating hydrogen from the hydrogenation reactor contains a multi-phase and multi-component mixture such as oil, water, hydrogen sulfide, and solid particles. In the process of recycling hydrogen, desulfurization treatment must be carried out; the circulating hydrogen mixture After exiting the hydrogenation reactor, it enters the high-pressure separator from the inlet of the cyclone-enhanced high-pressure separator, and performs dehydration and dehydrocarbon treatment in the cyclone-enhanced high-pressure separator. The large liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com