Straight-run diesel oil deacidification method and device for achieving same

A technology for straight-run diesel oil and deacidification, which is applied in the direction of multi-stage series-connected refining process treatment, etc., can solve the problems of long time required, high cost, and no problems, and achieves simple structure, convenient operation, and easy implementation of the production device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

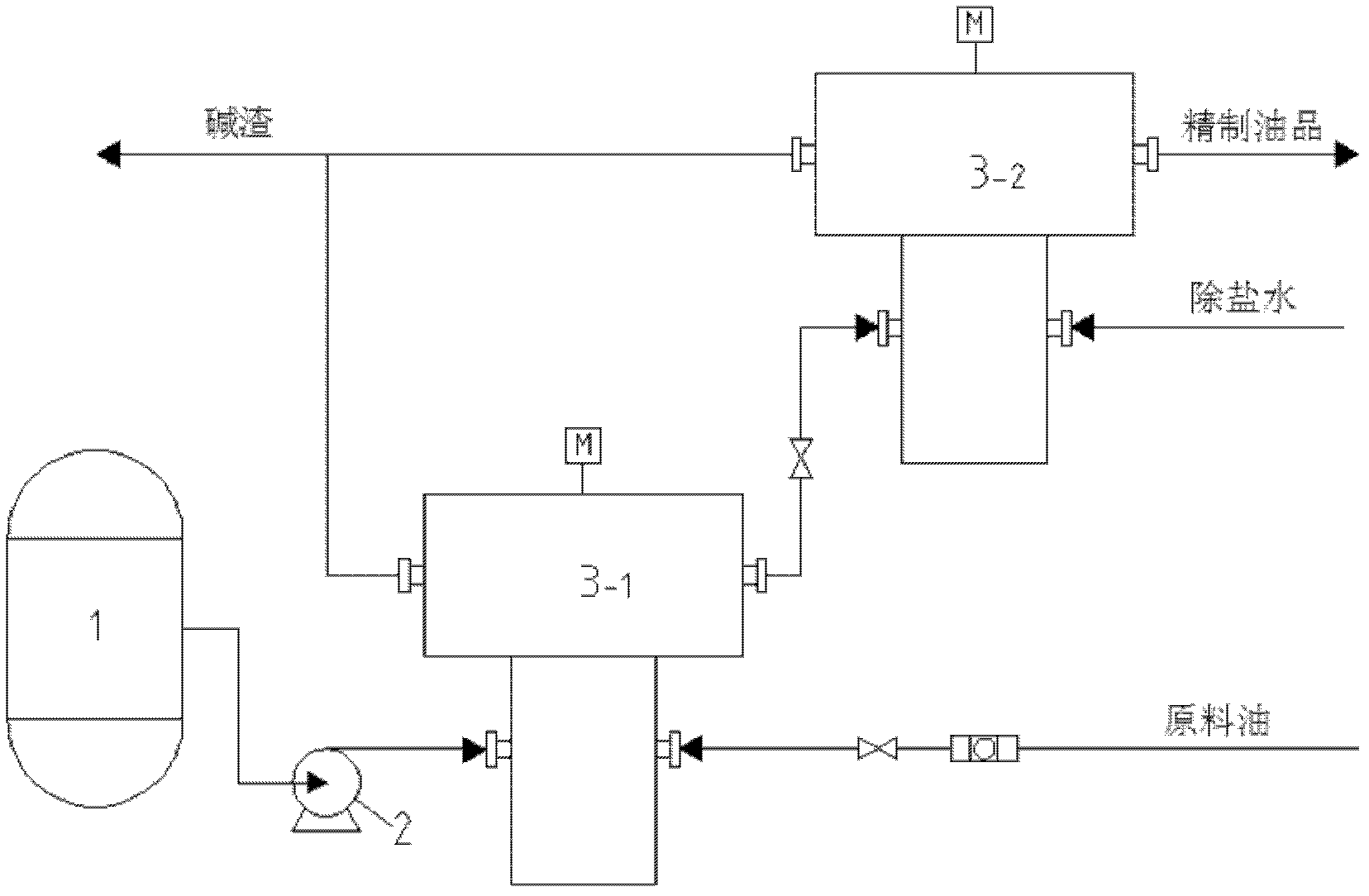

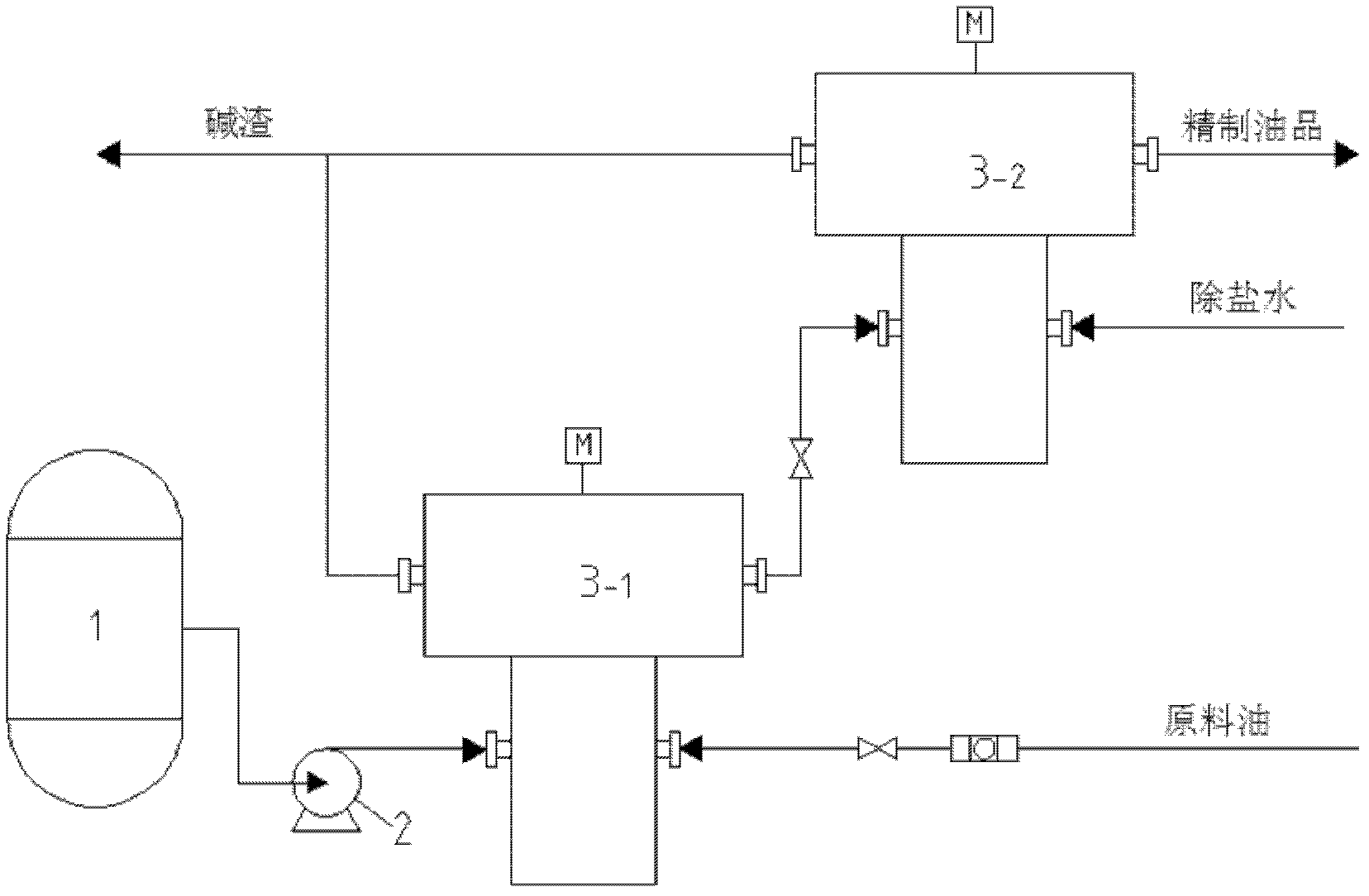

[0037] Attached figure 1 Shown is the process of straight-run diesel oil deacidification, where

[0038] 1. Material properties

[0039] (1) Raw material oil: flow rate is 10t / h, temperature is 65°C, density is 824kg / m3, acidity is 27.5mg / (100ml)

[0040] (2) Alkali: the mass fraction of alkali injection (when the rate of alkali injection solution is constant, the sodium hydroxide in the alkali injected in the device accounts for the percentage of the total mass of the solution) is 15%, the flow rate is 1.5t / h, and the temperature is 65 ℃

[0041] (3) Demineralized water: the flow rate is 0.8t / h, the temperature is 65°C, and the density is 1000kg / m3

[0042]2. The motor speed of centrifugal extraction separator is 900r / min.

[0043] 3. Content determination method

[0044] (1) Measuring method of acidity of refined oil products: infrared absorption spectrometry

[0045] (2) Measuring method of oil content in alkali slag: fluorescence analysis method

[0046] (3) Measuri...

Embodiment 2

[0052] 1. Material properties

[0053] (1) Raw material oil: flow rate is 10t / h, temperature is 65°C, density is 824kg / m3, acidity is 27.5mg / (100ml)

[0054] (2) Alkali: the mass fraction of alkali injection (when the rate of alkali injection solution is constant, the sodium hydroxide in the alkali injected in the device accounts for the percentage of the total mass of the solution) is 12%, the flow rate is 1.5t / h, and the temperature is 65 ℃

[0055] (3) Demineralized water: the flow rate is 0.8t / h, the temperature is 65°C, and the density is 1000kg / m3

[0056] 2. The motor speed of centrifugal extraction separator is 900r / min.

[0057] 3. Content determination method

[0058] (1) Measuring method of acidity of refined oil products: infrared absorption spectrometry

[0059] (2) Measuring method of oil content in alkali slag: fluorescence analysis method

[0060] (3) Measuring method of water content in refined oil products: capacitive sensor method

[0061] 4. Applicati...

Embodiment 3

[0066] 1. Material properties

[0067] (1) Raw material oil: the flow rate is 10t / h, the temperature is 65°C, the density is 825kg / m3, and the acidity is 27.5mg / (100ml)

[0068] (2) Alkali: the mass fraction of alkali injection (when the rate of alkali injection solution is constant, the sodium hydroxide in the alkali injected in the device accounts for the percentage of the total mass of the solution) is 10%, the flow rate is 1.5t / h, and the temperature is 65 ℃

[0069] (3) Demineralized water: the flow rate is 0.8t / h, the temperature is 65°C, and the density is 1000kg / m3

[0070] 2. The motor speed of centrifugal extraction separator is 900r / min.

[0071] 3. Content determination method

[0072] (1) Measuring method of acidity of refined oil products: infrared absorption spectrometry

[0073] (2) Measuring method of oil content in alkali slag: fluorescence analysis method

[0074] (3) Measuring method of water content in refined oil products: capacitive sensor method

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com