A method for reducing a sodium salt content of an alkaline-solution-containing crude alcohol ketone material

A lye and material technology, applied in the field of sodium salt removal in crude alcohol and ketone materials, can solve the problems of high energy consumption, large process water usage, incomplete sodium salt separation, etc., to prolong the operation period and reduce the output of waste water. , the effect of prolonging the driving cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

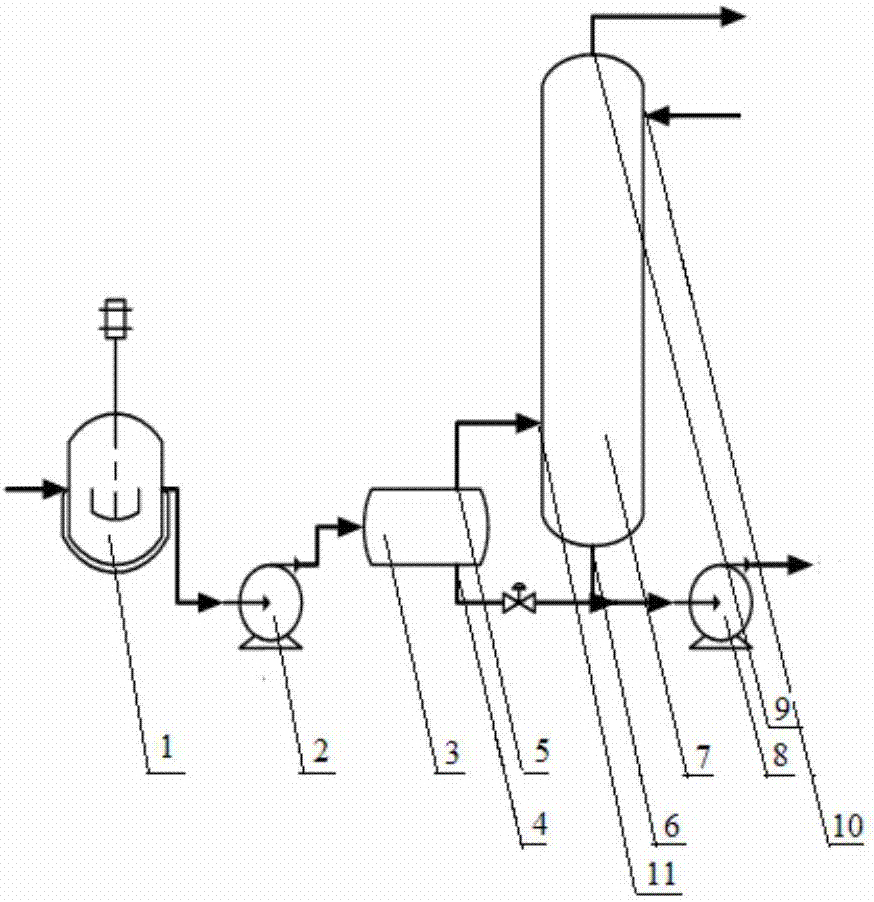

Image

Examples

Embodiment 1

[0045] A cyclohexanone plant with an annual output of 80,000 tons has a ventilation volume of about 14,000Nm 3 / h, the alkalinity of saponification is about 0.95mol / kg, and the amount of crude alcohol ketone material entering the saponification system is 12t / h, which is processed by the crude alcohol ketone material desalination device of the present invention, and the pressure difference between the inlet and outlet of the cyclone separator is 0.2MPa , the average washing volume of the salt extraction tower is 3.5m 3 / h, the average content of sodium ions in the alcohol and ketone materials from the salt extraction tower is 6ppm, and the amount of waste alkali sent to the waste alkali evaporation process is 11.5m 3 / h, the driving cycle can be increased to more than 12 months.

[0046] If the salt extraction tower is directly used for treatment, the average water washing volume of the salt extraction tower is 4.0m 3 / h, the average content of sodium ions in the alkanol and ...

Embodiment 2

[0048] A cyclohexanone plant with an annual output of 80,000 tons, with a ventilation volume of 14,000Nm 3 / h, the alkalinity of saponification is 0.95mol / kg, and the amount of crude alcohol ketone material entering the saponification system is 12t / h, which is processed by the crude alcohol ketone material desalination device of the present invention, and the pressure difference between the inlet and outlet of the cyclone separator is 0.15MPa, The average washing volume of the salt extraction tower is 3.25m 3 / h, the average content of sodium ions in the alcohol and ketone materials coming out of the salt extraction tower material is 7ppm, and the amount of waste alkali sent to the waste alkali evaporation process is 11.5m 3 / h, the driving cycle can be increased to more than 12 months.

Embodiment 3

[0050] A cyclohexanone plant with an annual output of 80,000 tons has a ventilation volume of about 14,000Nm 3 / h, the alkalinity of saponification is 0.95mol / kg, the amount of crude alcohol ketone material entering the saponification system is about 12t / h, the material coming out of the saponification system is processed by the sodium salt removal device of the present invention, and the alcohol ketone material is separated by sedimentation The residence time in the tower is 1 hour, and the average washing volume of the salt extraction tower is 3m 3 / h, the average content of sodium ions in the alcohol and ketone materials coming out of the salt extraction tower material is 6.5ppm, and the average waste alkali amount sent to the waste alkali evaporation process is 11m 3 / h, the operation cycle of the device is more than 12 months.

[0051] The material from the saponification system is treated by a separate salt extraction tower, and the average water washing volume of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com