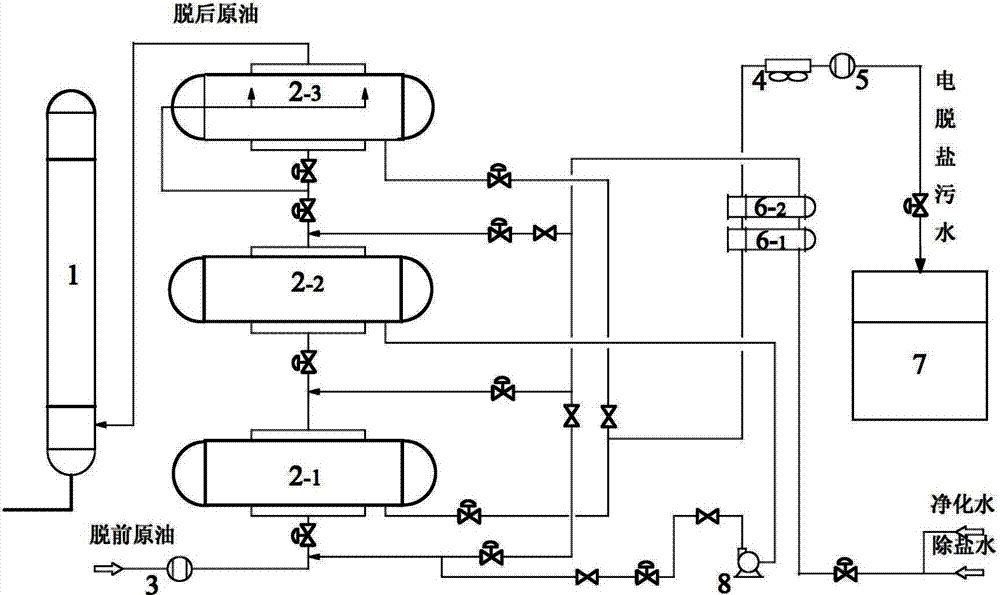

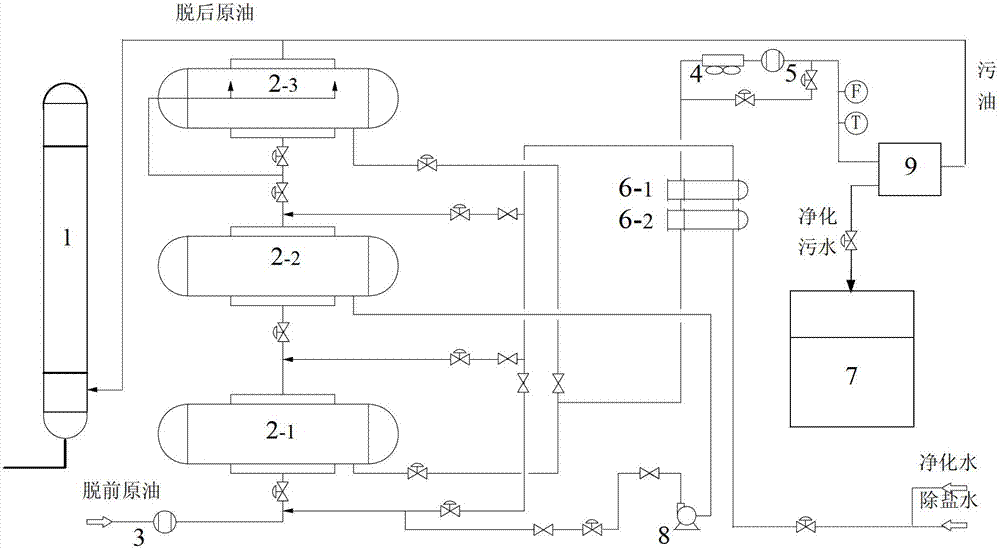

Crude oil processing unit containing electro-desalted sewage oil remover and method of crude oil processing unit

A crude oil processing and electric desalination technology, which is applied in the fields of grease/oily substance/float removal devices, petroleum industry, separation methods, etc. Fast, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

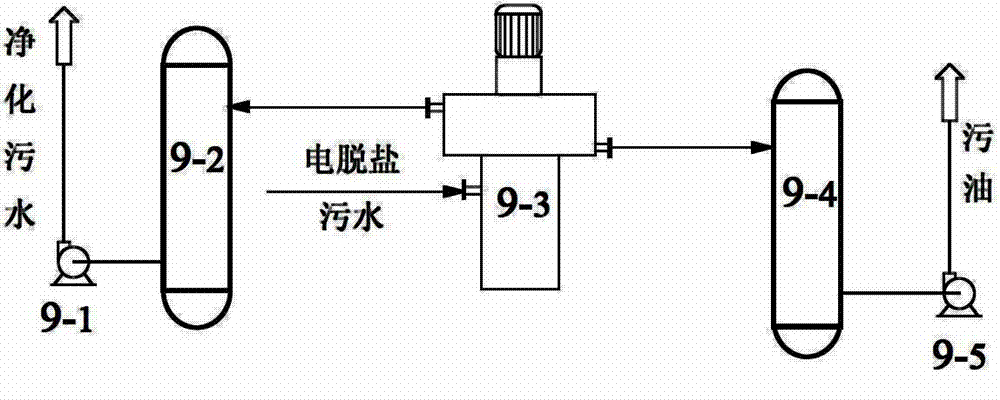

[0041] According to the aforementioned process flow, the degreasing of the electric desalination sewage is carried out, wherein

[0042] 1. Material properties

[0043] Desalination sewage: flow rate is 20t / h, temperature is 75℃, water density is 1000kg / m 3 , oil density 945kg / m 3 (20℃), oil viscosity is 303mm 2 / s(50℃), oil content 20000mg / L

[0044] 2. The diameter of the drum of the centrifugal extraction separator is 500mm, and the motor speed is 1000rpm.

[0045] 3. Content determination method

[0046] Oil water content is determined according to GB / T8929-2006 Petroleum Product Moisture Determination Method

[0047] The oil concentration in water was determined according to GB / T16488-1996 Determination of water quality petroleum and animal and vegetable oils by infrared photometry.

[0048] 4. Apply Effects

[0049] After being treated by the centrifugal extraction separator, the oil content of the purified water is 44mg / L, the oil removal efficiency reaches 99.78...

Embodiment 2

[0051] 1. Material properties

[0052] Desalination sewage: flow rate is 30t / h, temperature is 60℃, water density is 1000kg / m 3 , oil density 910kg / m 3 (20℃), oil viscosity is 290mm 2 / s(50℃), oil content 1000mg / L

[0053] 2. The diameter of the drum of the centrifugal extraction separator is 600mm, and the motor speed is 1000rpm.

[0054] 3. Content determination method

[0055] Oil water content is determined according to GB / T8929-2006 Petroleum Product Moisture Determination Method

[0056] The oil concentration in water was determined according to GB / T16488-1996 Determination of water quality petroleum and animal and vegetable oils by infrared photometry.

[0057] 4. Apply Effects

[0058] After being treated by the centrifugal extraction separator, the oil content of the purified water is 210mg / L, the oil removal efficiency reaches 79%, the water content of the light-phase outlet slop oil is less than 1%, the main indicators are good, and the properties are similar ...

Embodiment 3

[0060] 1. Material properties

[0061] Desalination sewage: flow rate is 10t / h, temperature is 65℃, water density is 1000kg / m 3 , oil density 935kg / m 3 (20℃), oil viscosity is 300mm 2 / s(50℃), oil content 30000mg / L

[0062] 2. The diameter of the drum of the centrifugal extraction separator is 450mm, and the motor speed is 1000rpm.

[0063] 3. Content determination method

[0064] The water content of oil is determined according to GB / T 8929-2006 Petroleum Product Moisture Determination Method

[0065] The oil concentration in water was determined according to GB / T16488-1996 Determination of water quality petroleum and animal and vegetable oils by infrared photometry.

[0066] 4. Apply Effects

[0067] After being treated by the centrifugal extraction separator, the oil content of the purified water is 77mg / L, the oil removal efficiency reaches 99.23%, the water content of the light-phase outlet slop oil is less than 1%, the main indicators are good, and the properties a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com