Coking emptying tower oily wastewater treatment device and method

A wastewater treatment and venting tower technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of limited treatment effect, long treatment time, inconvenient maintenance, etc., and achieve good economic benefits And social benefits, convenient operation, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

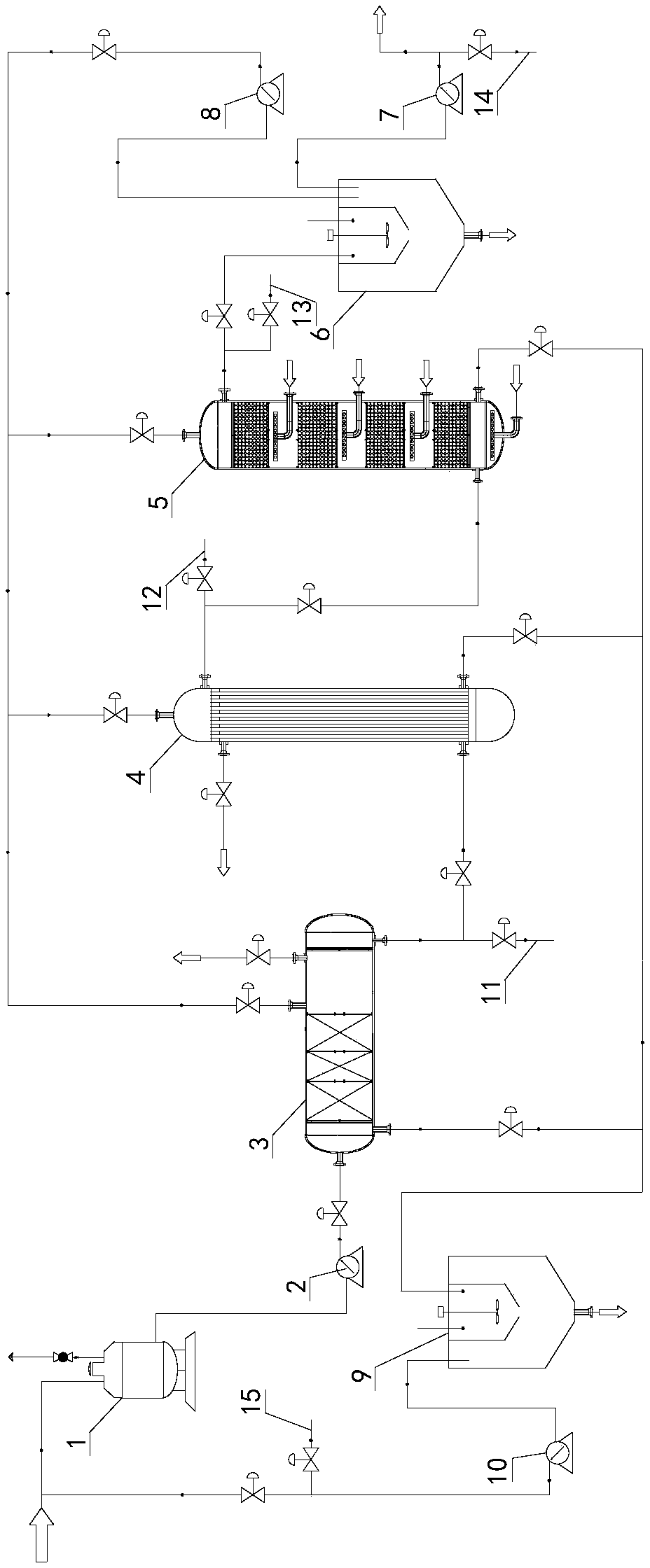

Method used

Image

Examples

Embodiment 1

[0116] The oily waste water from the coking blowdown tower of Refinery 1# is yellow in appearance and has a pungent odor. The pH value is 6.0-6.5. It is acidic organic waste water containing phenols, polycyclic aromatic compounds and heterocycles containing nitrogen, oxygen and sulfur. Organic compounds, etc., have serious emulsification, and the oil content seriously exceeds the standard, and the oil content is 8000-10000mg / L.

[0117] After the raw water is first purified by the coalescer 3, the water content of the recovered oil is 0.3%, and the oil content in the water is reduced to 980mg / L; after being treated by the membrane separator 4, the water content of the recovered oil is 0.3%, and the oil content in the water reduced to 200mg / L; finally after micro-electrolysis treatment, after flocculation and sedimentation in the settling tank 6, the oil content in the wastewater is lower than 5mg / L, and the oil content in the purified wastewater meets the requirements of the pe...

Embodiment 2

[0119] The oily waste water from the coking blowdown tower of refinery 2# is dark green in appearance, has a pungent smell, and has a pH value of 7.5 to 8.0. 9000mg / L.

[0120] After the raw water is first purified by the coalescer 3, the water content of the recovered oil is 0.3%, and the oil content in the water is reduced to 900mg / L; after being treated by the membrane separator 4, the water content of the recovered oil is 0.3%, and the oil content in the water Reduced to 150mg / L; finally after micro-electrolysis treatment, after flocculation and sedimentation in the settling tank 6, the oil content in the wastewater is lower than 3mg / L, and the oil content in the purified wastewater meets the requirements of the petroleum refining industry discharge standard [GB31570-2015] The technical requirements have solved the problem of oily wastewater treatment in the coking vent tower, and realized the deep purification treatment of oily wastewater. During the operation of the dev...

Embodiment 3

[0122] The oily wastewater from the coking blowdown tower of Refinery 3# is yellow in appearance, with a pH value of 5.5-6.5, which is acidic organic wastewater containing phenols, polycyclic aromatic compounds, etc., and its oil content is 6000-8000mg / L.

[0123] After the raw water is first purified by the coalescer 3, the water content of the recovered oil is 0.3%, and the oil content in the water is reduced to 800mg / L; after being treated by the membrane separator 4, the water content of the recovered oil is 0.3%, and the oil content in the water Reduced to 120mg / L; finally after micro-electrolysis treatment, after flocculation and sedimentation in the settling tank 6, the oil content in the wastewater is lower than 3mg / L, and the oil content in the purified wastewater meets the requirements of the petroleum refining industry discharge standard [GB31570-2015] The technical requirements have solved the problem of oily wastewater treatment in the coking vent tower, and realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com