Method and device for recycling caprolactam in benzene distillation residual liquid

A technology of caprolactam and residual liquid distillation, which is applied in the field of caprolactam recycling, can solve problems such as loss, and achieve the effects of solving loss, reducing environmental pollution and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

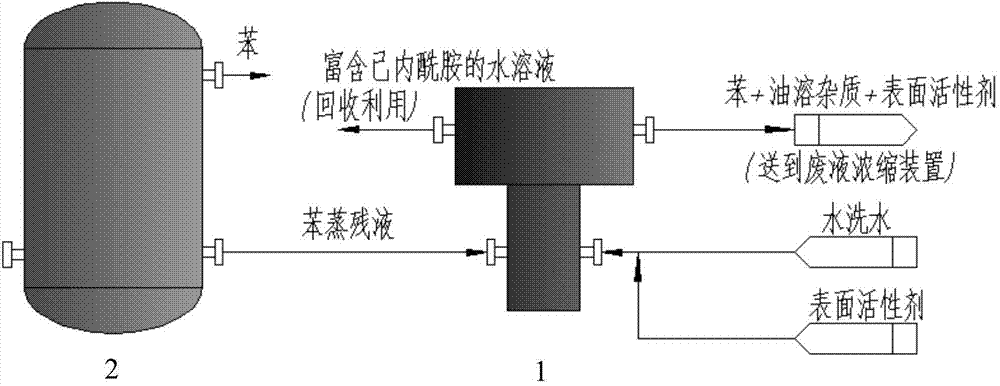

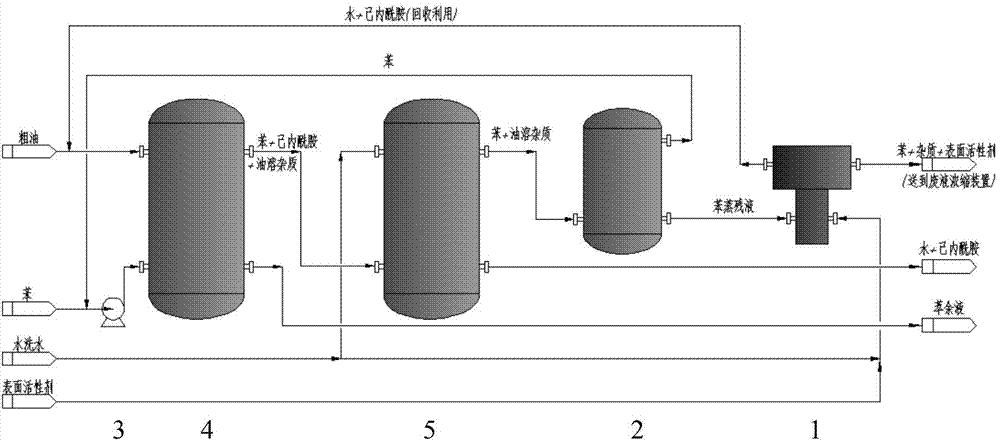

[0067] In a 200t / year benzene distillation raffinate recovery unit, according to figure 1 In the separation process of the amidation reaction solution shown, the caprolactam in the benzene distillation raffinate is separated and recovered by the method of the present invention, and the purpose of recovering caprolactam in the benzene distillation raffinate is achieved with high efficiency, high precision and low energy consumption. The economic benefit of caprolactam recovery is greatly improved, and the environmental protection problem is solved. Its specific operation process and effect are as follows:

[0068] 1. Material properties

[0069] (1) Benzene raffinate: the material is a mixture of organic phase and inorganic phase, the content of caprolactam is about 40%, and the impurity content is about 20%. The rated flow rate is 2t / h, the temperature is 60-80°C, and the average is about 70°C.

[0070] (2) Washing water: the content of surfactant (mixed fatty acid glycerid...

Embodiment 2

[0078] In a 200t / year benzene distillation raffinate recovery unit, according to figure 1 In the separation process of the amidation reaction solution shown, the method of the present invention is used to separate and recover the caprolactam in the benzene distillation raffinate, so as to achieve the purpose of recovering caprolactam in the benzene distillation raffinate with high efficiency, high precision and low energy consumption, so that The economic benefit of caprolactam recovery is greatly improved, and the environmental protection problem is solved. Its specific operation process and effect are as follows:

[0079] 1. Material properties

[0080] (1) Benzene raffinate: the material is a mixture of organic phase and inorganic phase, the content of caprolactam is about 40%, and the impurity content is about 20%. The rated flow rate is 2t / h, the temperature is 60-80°C, and the average is about 70°C.

[0081] (2) Washing water: the content of surfactant (mixed fatty ac...

Embodiment 3

[0089] In a 200t / year benzene distillation raffinate recovery unit, according to figure 1 In the separation process of the amidation reaction solution shown, the method of the present invention is used to separate and recover the caprolactam in the benzene distillation raffinate, so as to achieve the purpose of recovering caprolactam in the benzene distillation raffinate with high efficiency, high precision and low energy consumption, so that The economic benefit of caprolactam recovery is greatly improved, and the environmental protection problem is solved. Its specific operation process and effect are as follows:

[0090] 1. Material properties

[0091] (1) Benzene raffinate: the material is a mixture of organic phase and inorganic phase, the content of caprolactam is about 40%, and the impurity content is about 20%. The rated flow rate is 2t / h, the temperature is 60-80°C, and the average is about 70°C.

[0092] (2) Washing water: surfactant (mixed fatty acid glyceride) con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com