Method and device for hydrocracking mineralized refuse cracked oil

A technology for mineralized waste and hydrocracking, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc. consumption, improve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

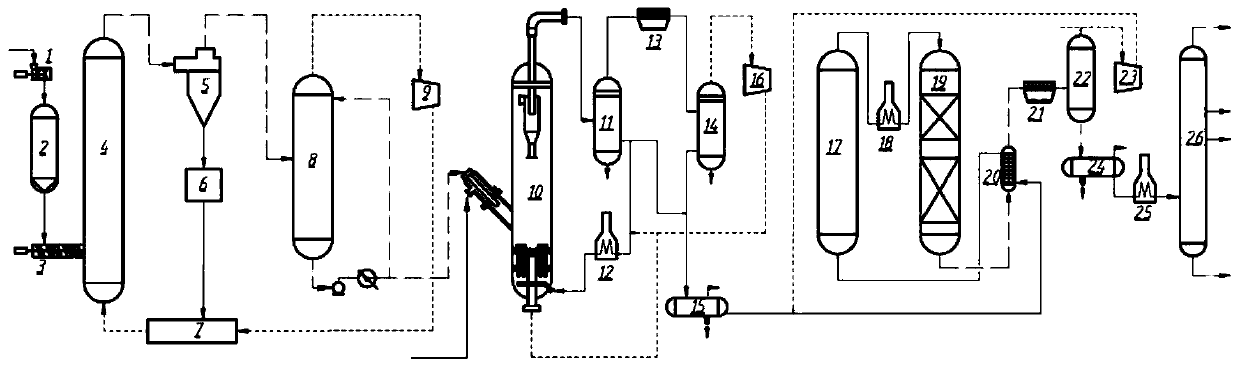

[0083] Example 1: 10,000 tons / day mineralized waste treatment process and device

[0084] In a mineralized waste treatment device with an annual treatment capacity of 10,000 tons / day, a set such as figure 1 The specific operation process and effects of the mineralized waste pyrolysis residue hydrocracking treatment unit shown are as follows:

[0085] Mined and recycled mineralized waste is naturally dried for a proper period of time, and the mineralized waste is crushed by a crusher and collected into a material tank, and then sent to a fluidized bed pyrolyzer for carbonization of organic matter by a screw feeder, and collected after pyrolysis The fixed charcoal and ash fall into the separation tank, and the separated pyrolytic charcoal and the non-condensable gas delivered by the compressor are sent to the heating furnace for combustion, and the combustion heat supplies heat to the fluidized bed pyrolyzer; after pyrolysis, the light phase The components are sent to the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com