Micro vortex flow tube arrangement method of recycle hydrogen de-hydrocarbon machine

A technology of a hydrodehydrocarbonizer and an arrangement method, which is applied in the field of swirling tube arrangement, can solve the problems of increasing equipment consumables and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

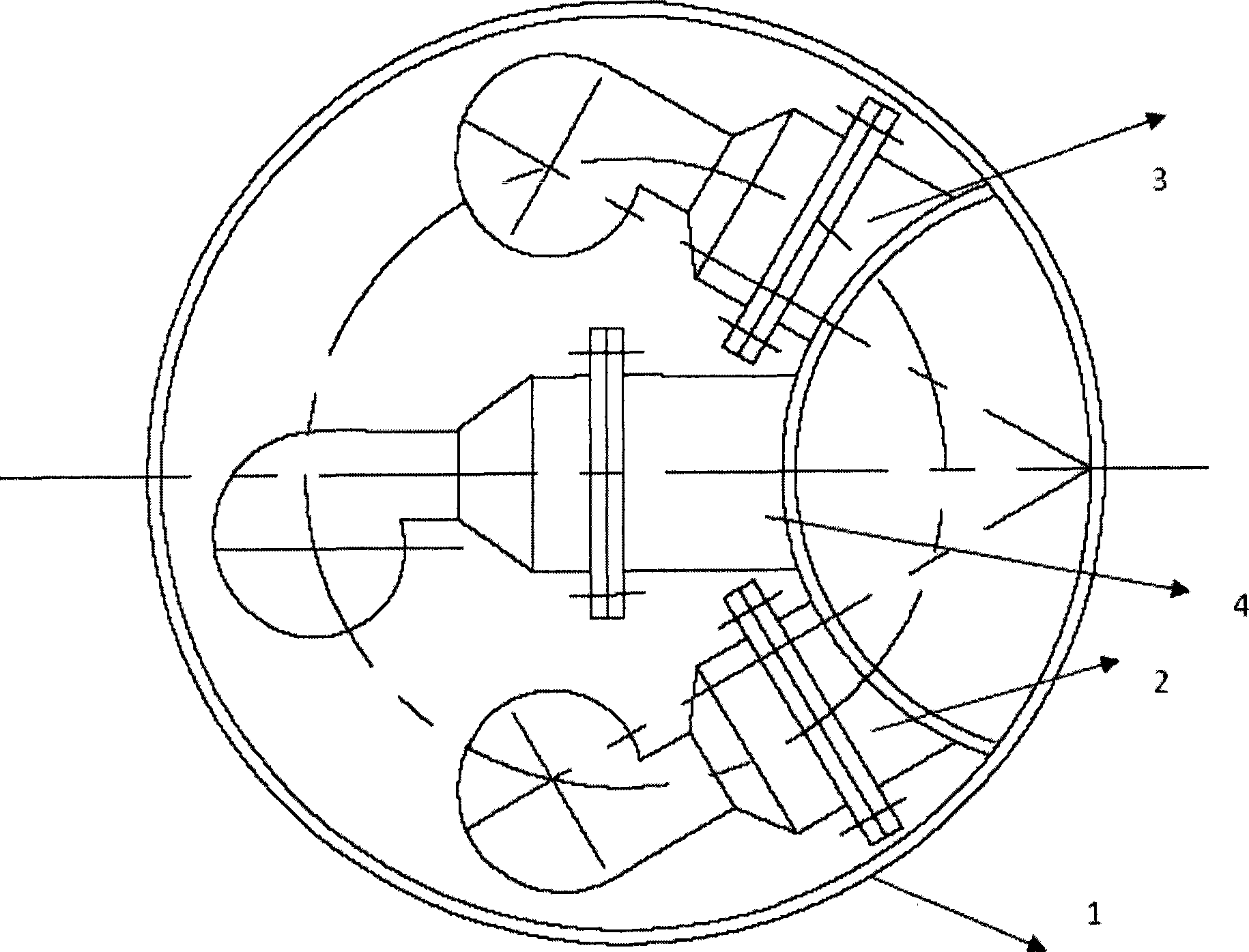

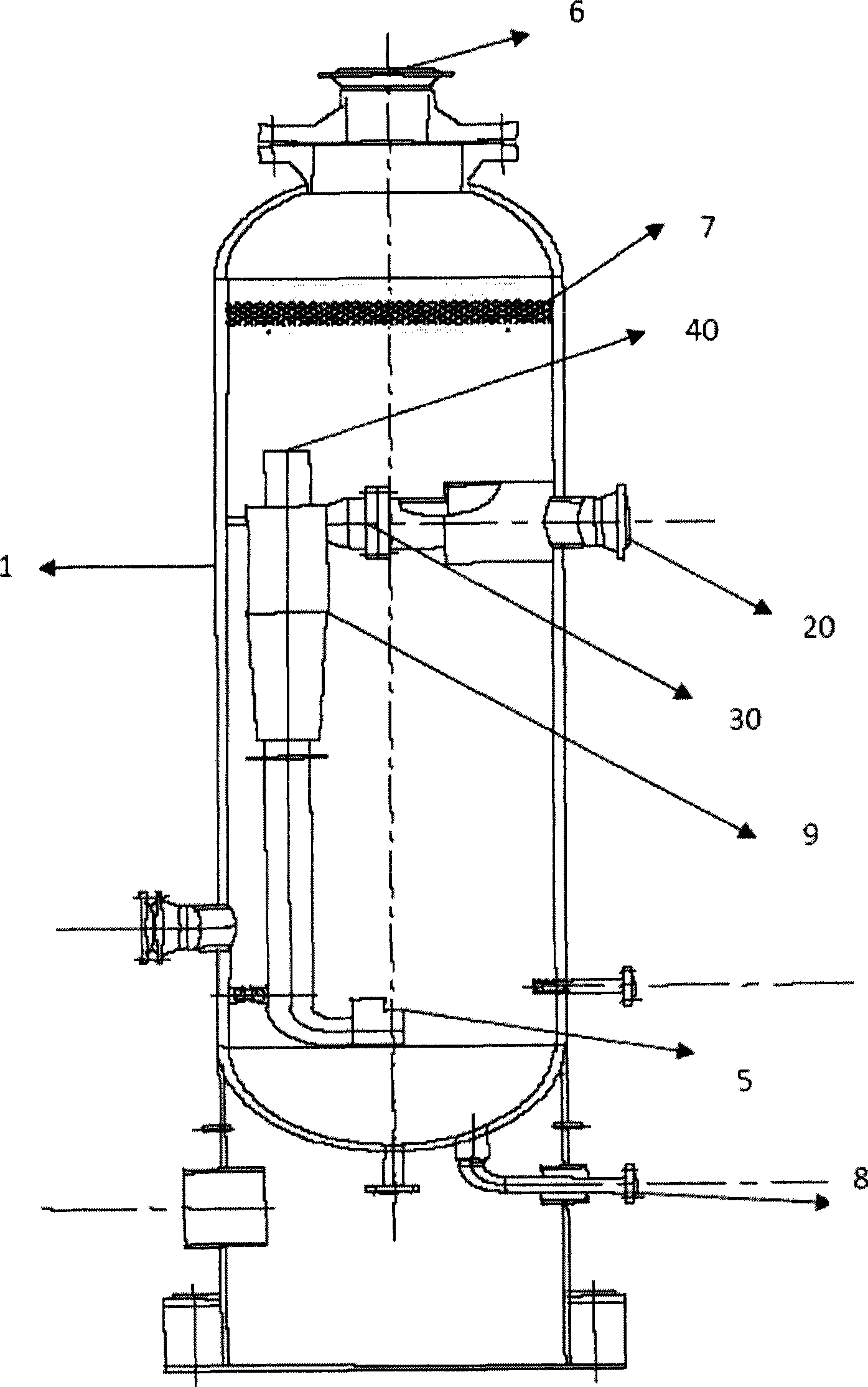

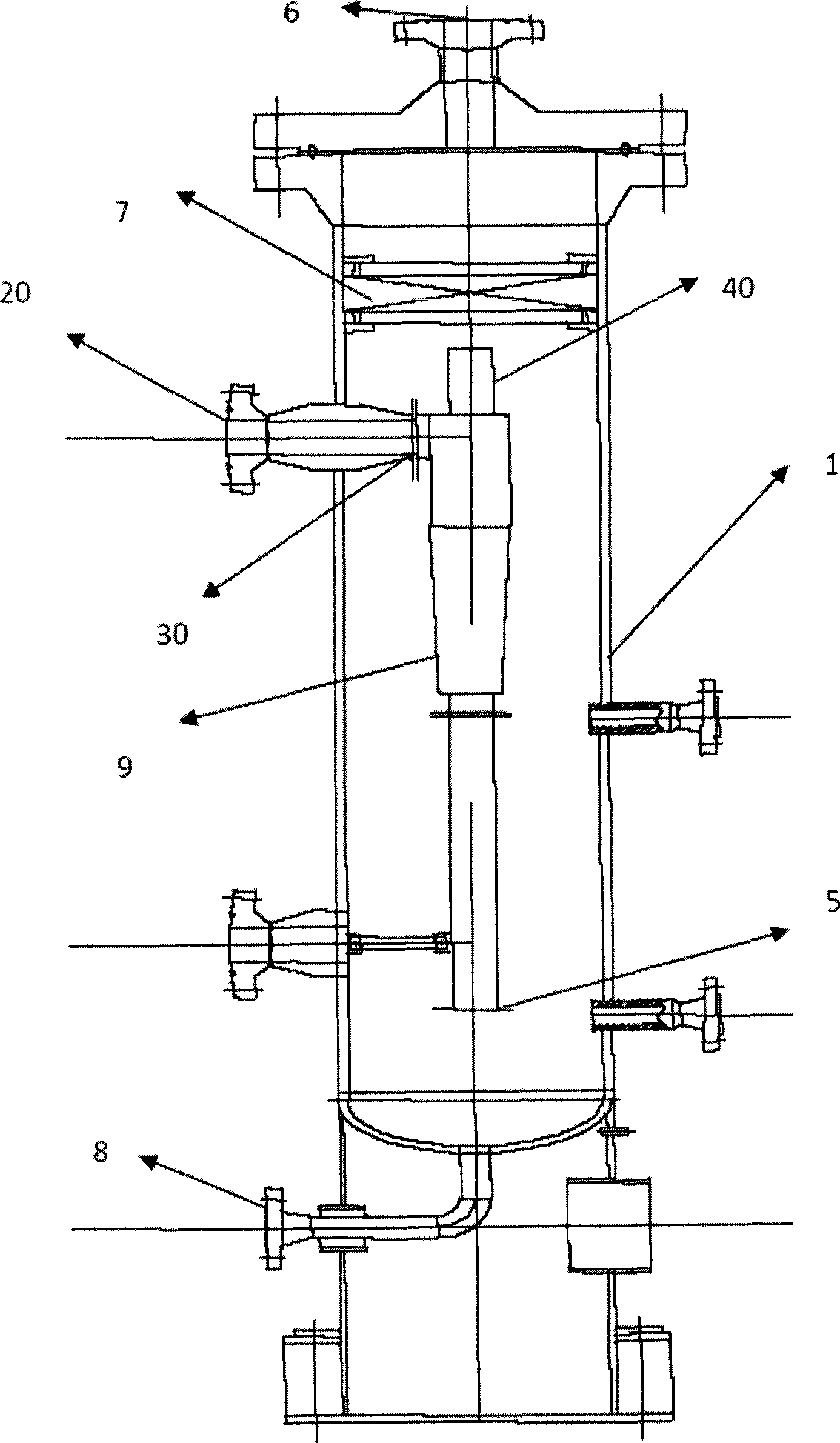

[0023] After extensive and in-depth research, the inventors of the present invention found that the separation time of the circulating hydrogen mixture can be reduced by collecting all the inlets of the micro-swirl tube or the group of micro-swirl tubes and sealingly connecting them with the inlet pipe of the pressure vessel , the cancellation of the sub-chamber tube sheet in the original cyclone can effectively reduce the investment cost of the decarburizer steel and shorten the equipment processing cycle. In addition, the equilateral triangle arrangement of the micro-swirl tube group makes the interior of the equipment more compact, and at the same time Improved device stability. The present invention has been accomplished based on the above findings.

[0024] Technical conception of the present invention is as follows:

[0025] The circulating hydrodecarburizer cancels the tube sheet in the original cyclone, and the mixed gas enters the cyclone tube directly from the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com