Method and device for extracting hexahydrobenzoic acid from rearrangement reaction liquid

A hexahydrobenzoic acid and rearrangement reaction technology, applied in the separation/purification of carboxylic acid compounds, etc., can solve the problems of sulfonation loss, gravity settling tank can not be used for separation time, large equipment investment and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

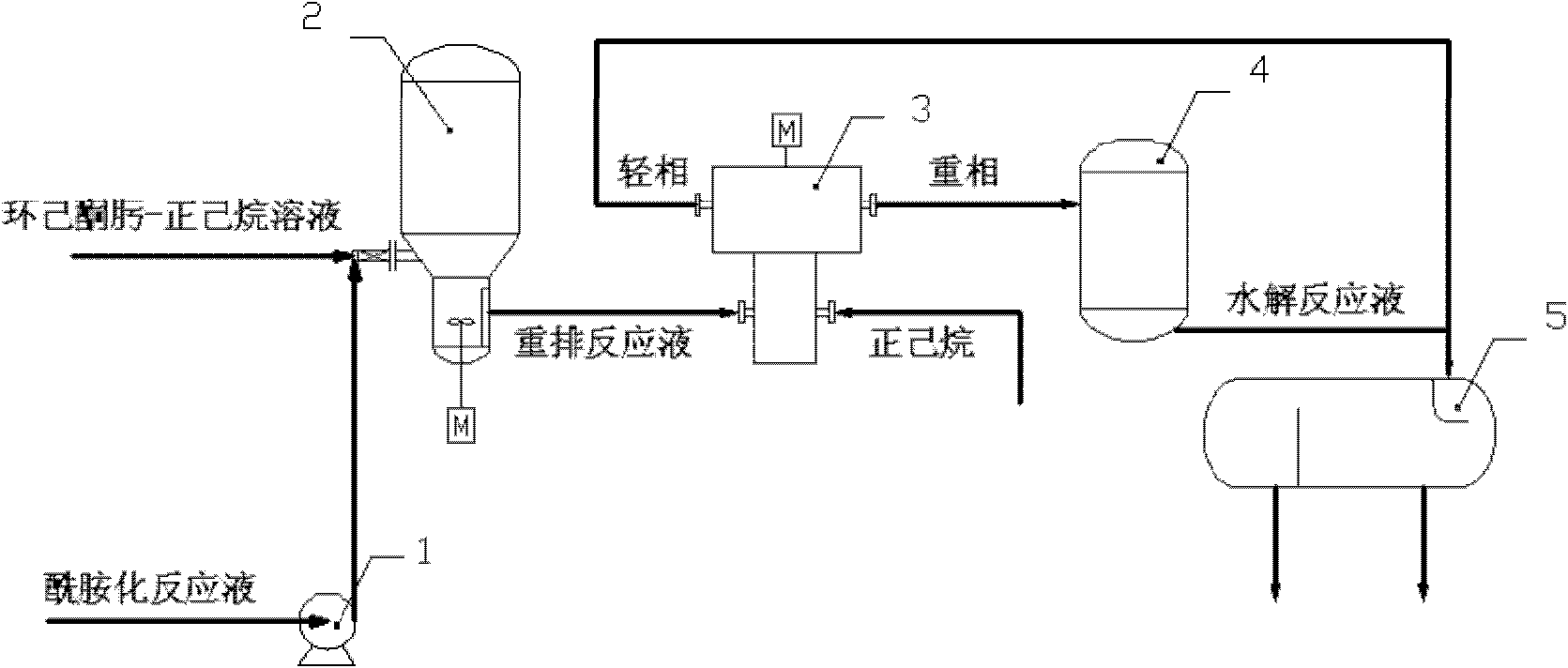

[0049] according to figure 1 The process flow shown carries out the separation of the amidation reaction liquid.

[0050] 1. Material properties

[0051] (1) Rearrangement reaction solution: the material is a mixture of organic phase and inorganic phase, and the content of CCA fluctuates between 20-25%. The rated flow rate is 20 tons / hour, the temperature is 60-80°C, the average temperature is about 70°C, and the density is 1270kg / m 3 , the viscosity is 263mpa·s.

[0052] (2) n-Hexane: flow rate 2.0 tons / hour, temperature 50-60°C, average temperature about 57°C, density 761kg / m 3 , the viscosity is 0.26mpa·s.

[0053] 2. The motor speed of the centrifugal extractor is 900 rpm.

[0054] 3. Content determination method:

[0055] Using gas chromatography.

[0056] 4. Application effect

[0057] (1) 2.0 tons / hour of n-hexane at normal temperature is added, the content of the light phase in the heavy phase after separation is less than 1%, and the content of the heavy phase...

Embodiment 2

[0060] according to figure 1 The process flow shown carries out the separation of the amidation reaction liquid.

[0061] 1. Material properties

[0062] (1) Rearrangement reaction solution: the material is a mixture of organic phase and inorganic phase, and the content of CCA fluctuates between 20-25%. The rated flow rate is 20 tons / hour, the temperature is 60-80°C, the average temperature is about 70°C, and the density is 1270kg / m 3 , the viscosity is 263mpa·s.

[0063] (2) n-Hexane: The flow rate is 4.0 tons / hour, the temperature is 50-60°C, the average temperature is about 57°C, and the density is 761kg / m 3 , the viscosity is 0.26mpa·s.

[0064] 2. The motor speed of the centrifugal extractor is 900 rpm.

[0065] 3. Content determination method

[0066] Using gas chromatography.

[0067] 4. Application effect

[0068] (1) 4.0 tons / hour of normal-temperature n-hexane is added, the content of the light phase in the heavy phase after separation is less than 0.8%, and ...

Embodiment 3

[0071] according to figure 1 The process flow shown carries out the separation of the amidation reaction liquid.

[0072] 1. Material properties

[0073] (1) Rearrangement reaction solution: the material is a mixture of organic phase and inorganic phase, and the content of CCA fluctuates between 20-25%. The rated flow rate is 20 tons / hour, the temperature is 60-80°C, the average temperature is about 70°C, and the density is 1270kg / m 3 , the viscosity is 263mpa·s.

[0074] (2) n-Hexane: The flow rate is 8.0 tons / hour, the temperature is 50-60°C, the average temperature is about 57°C, and the density is 761kg / m 3 , the viscosity is 0.26mpa·s.

[0075] 2. The motor speed of the centrifugal extractor is 900 rpm.

[0076] 3. Content determination method

[0077] Using gas chromatography.

[0078] 4. Application effect

[0079] (1) 8.0 tons / hour of n-hexane at normal temperature is added, the content of the light phase in the heavy phase after separation is less than 0.5%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com