High-carbon pulverized coal ash/coal slag decarbonization and classification method and device

A classification method, fly ash technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems that cannot meet the efficient utilization of fly ash, improve environmental and social benefits, and improve utilization rate , the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: Fly ash treatment of a power plant with a total installed capacity of 2 million KW

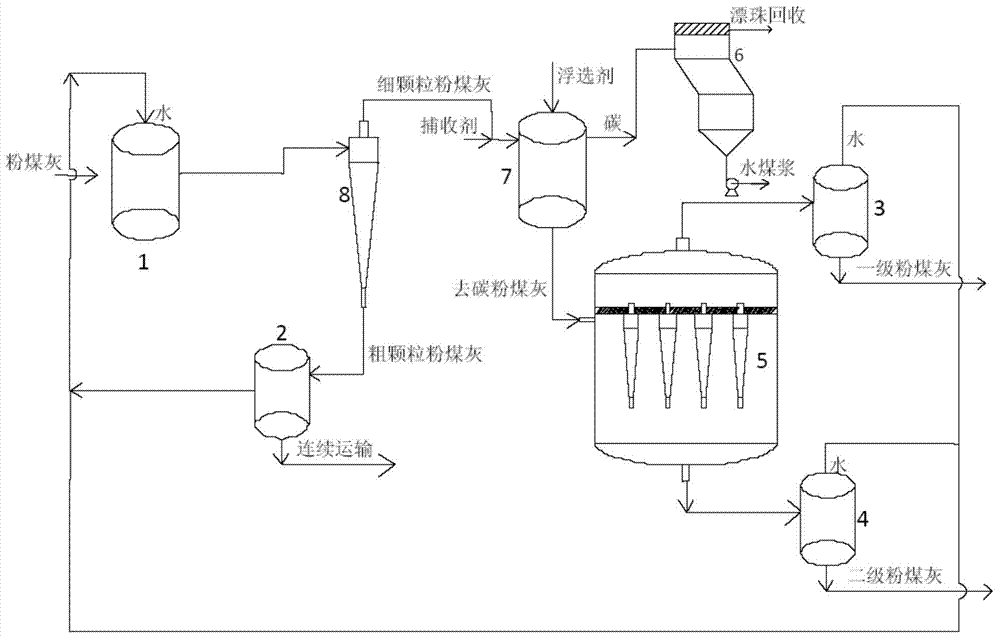

[0066] For a power plant with a total installed capacity of 2 million KW, a set such as figure 1 The fly ash decarbonization separation process shown, its specific operation process and effect are described as follows:

[0067] Firstly, make the water and fly ash fully mixed in the mixing tank, and it is in a wet state, and then start the solid-liquid cyclone separator, and the fine particle fly ash coming out of the overflow port of the cyclone separator must be decarbonized Treatment, the coarse-grained fly ash coming out of the bottom outlet of the cyclone separator is dehydrated through the settling tank, the coarse-grained fly ash is transported regularly and uninterrupted, and the collected water returns to the mixing tank to mix with the feed; the overflow is added to the Collecting agent, after pulp pretreatment, it is stirred evenly in the mixing tank and poure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com