Method for treating nickel smelting furnace slag

A technology of slag and rotary hearth furnace, which is applied in the field of processing nickel smelting slag, which can solve the problems of fluctuating product quality, complicated operation, and lengthy process, and achieve the effects of shortening the smelting cycle, low energy consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

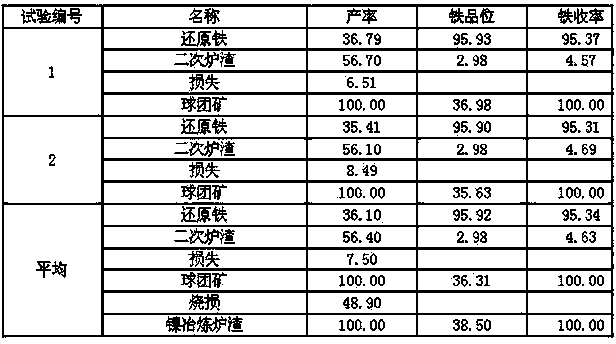

Embodiment 1

[0050] Operation steps of the present invention are:

[0051] Ingredients mixing: 3㎜Nickel industry smelting slag: 1 # Coal powder: limestone powder: bentonite = 64.5: 19.4: 12.9: 3.2, mix the above crushed and ground materials in proportion;

[0052] Ball briquetting: Add the above-mentioned raw materials prepared in proportion to the mixer, and after mixing evenly, use a double-roller briquetting machine to press it into pellets. The size of the pellets is 40×㎜25㎜×20㎜;

[0053] Drying: Dry the pressed pellets in an electric blast drying oven at 200°C for 3 hours, and the compressive strength after drying is greater than 300N;

[0054] Direct reduction in rotary hearth furnace: ① Preheating: Put the dried carbon-containing pellets into the preheating section of the rotary hearth furnace for preheating. The preheating temperature is 900°C and the preheating time is 25 minutes;

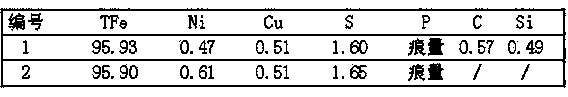

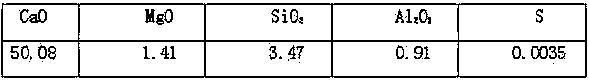

[0055] ②Direct reduction: The preheated carbon-containing pellets are reduced in the reduction se...

Embodiment 2

[0058] Operation steps of the present invention are:

[0059] Ingredients mixing: 1㎜Nickel industry smelting slag: 2 # Coal powder: limestone powder: NCP: bentonite = 69.4: 16.7: 6.9: 3.5: 3.5, mix the above crushed and ground materials in proportion;

[0060] Ball briquetting: Add the above-mentioned raw materials prepared in proportion to the mixer, and after mixing evenly, use a double-roller briquetting machine to press it into pellets. The size of the pellets is 40×㎜25㎜×20㎜;

[0061] Drying: Dry the pressed pellets in an electric blast drying oven at 200°C for 3 hours, and the compressive strength after drying is greater than 500N;

[0062] Direct reduction in rotary hearth furnace: ① Preheating: Put the dried carbon-containing pellets into the rotary hearth furnace and preheat in the preheating section. The preheating temperature is 900°C and the preheating time is 25 minutes;

[0063]② Reduction: The preheated carbon-containing pellets are reduced in the reduction sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com