Deep peak shaving system of thermal power plant

A thermal power plant, a deep technology, applied in the control system, steam superheating, heat storage equipment and other directions, can solve the problems of increasing the range from low load to high load, waste of energy, and poor adjustment performance of peak and valley power regulation, to reduce The effect of increasing the load, improving the economy, and increasing the amount of network input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

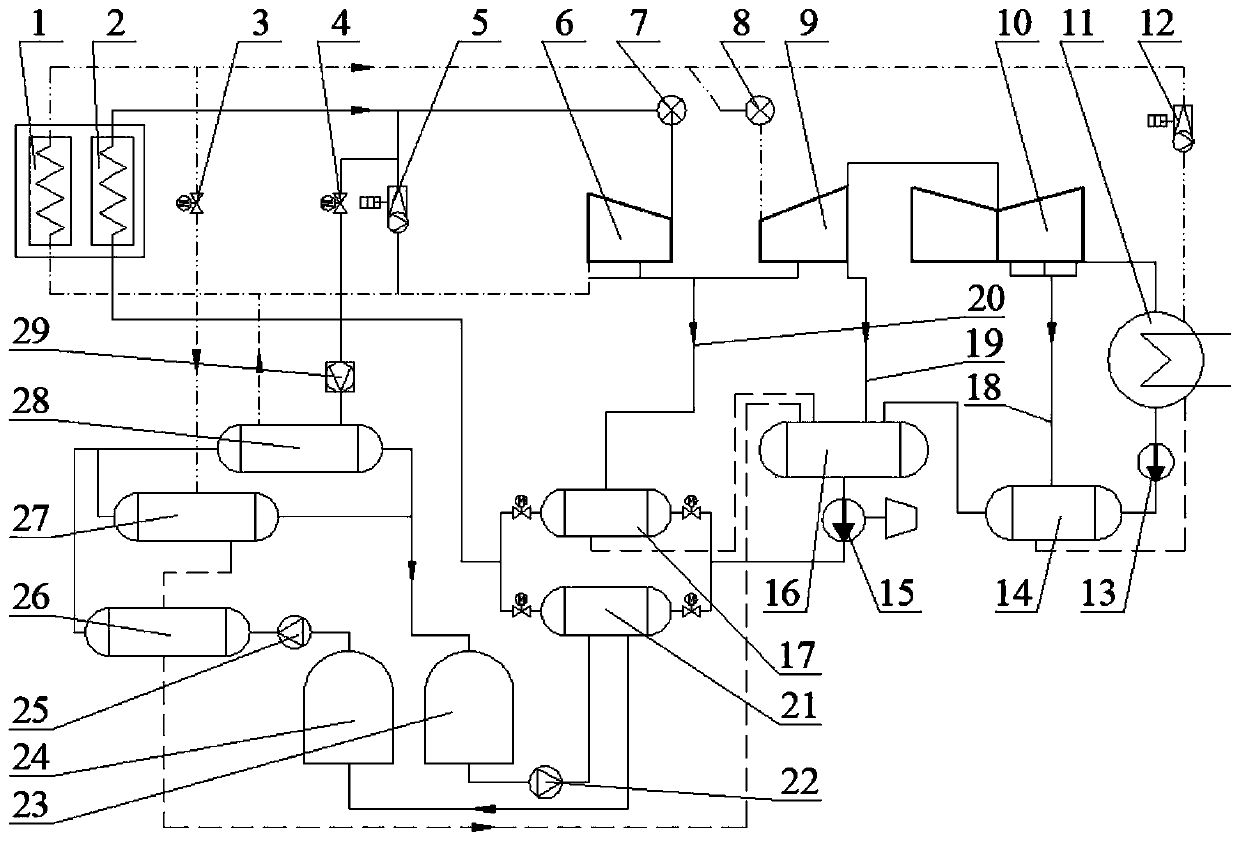

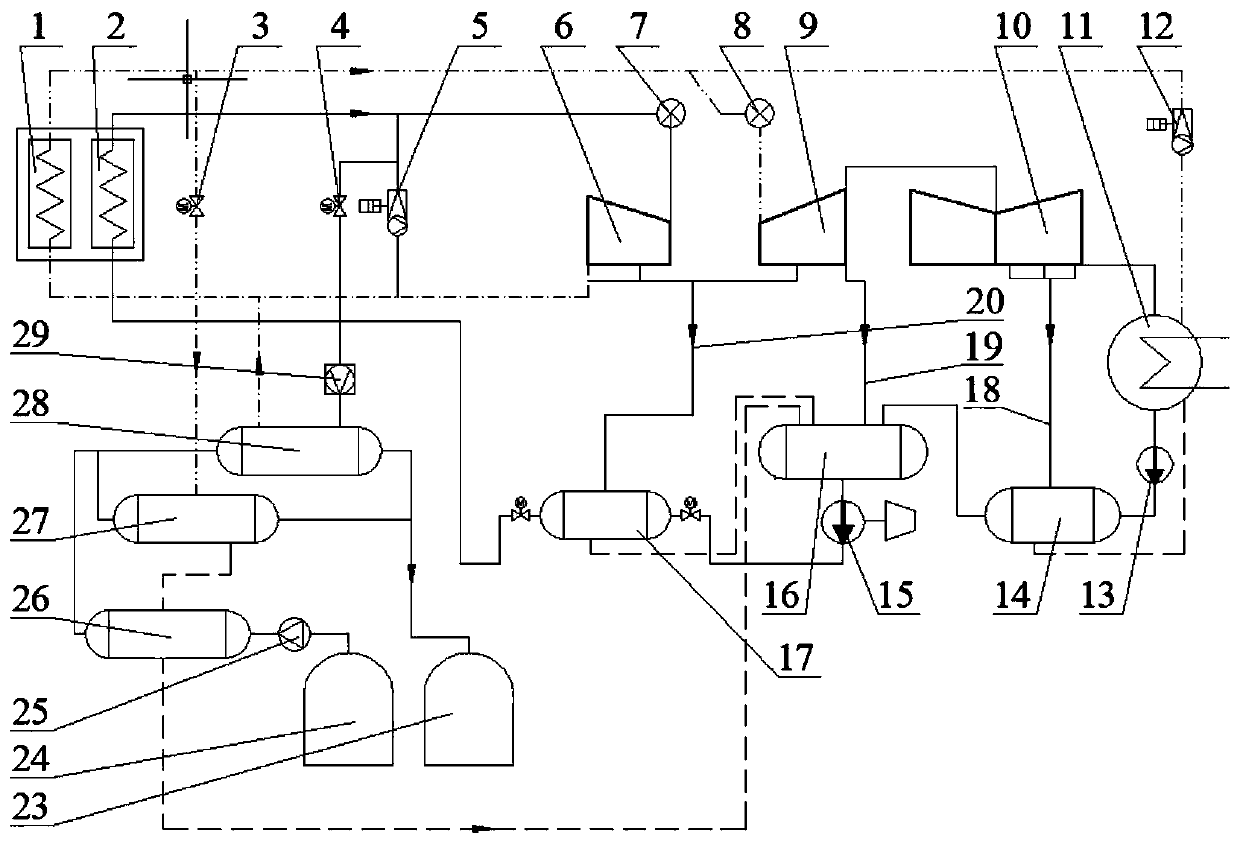

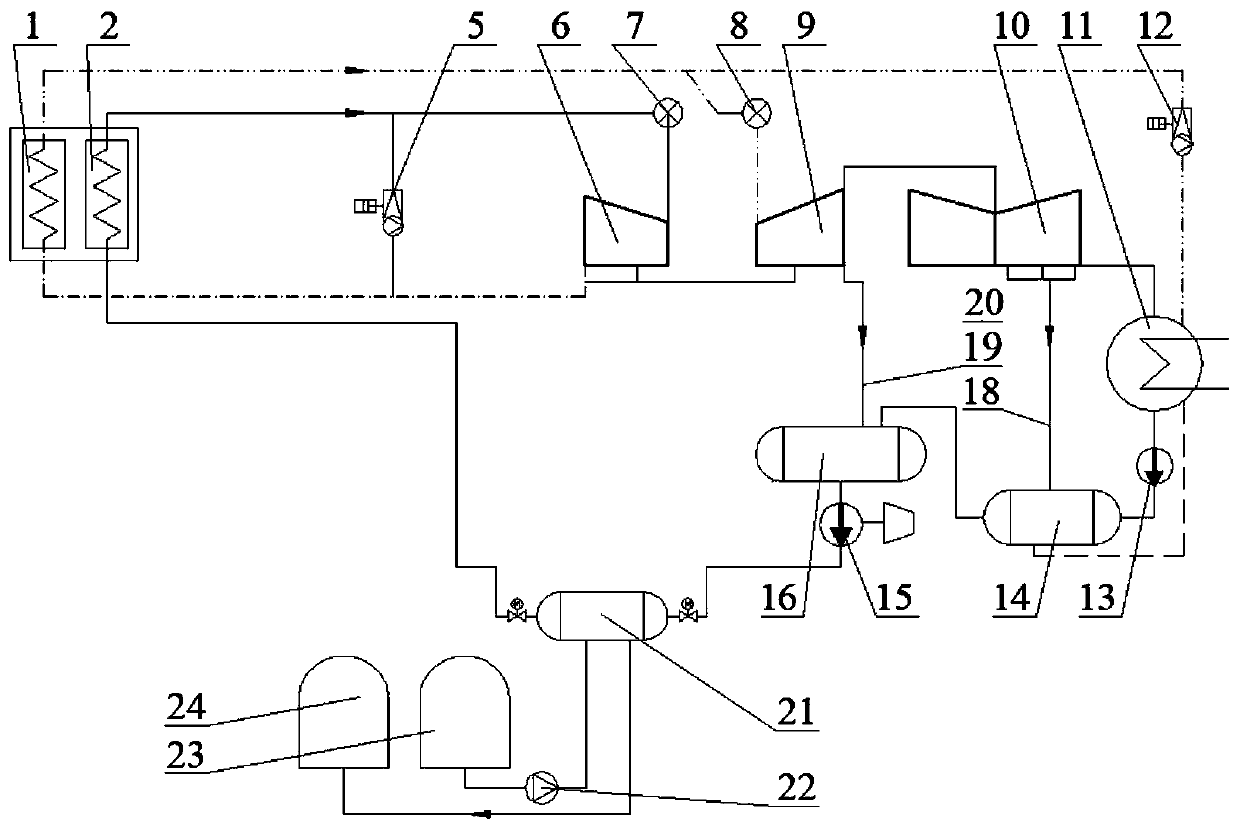

[0037] see figure 1 , figure 2 and image 3, a preferred embodiment of the deep peak-shaving system of a thermal power plant of the present invention, for specific component connections, see figure 1 , the heat storage process of unit load reduction and peak regulation, the working diagram is shown in figure 2 , the heat release process of the unit when the load is increased and the peak regulation is performed, the working diagram is shown in image 3 .

[0038] In a preferred embodiment of the deep peak-shaving system of a thermal power plant as described above, the load-reducing peak-shaving heat storage process of the unit:

[0039] Such as figure 2 As shown, when the steam turbine generator set responds to the deep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com