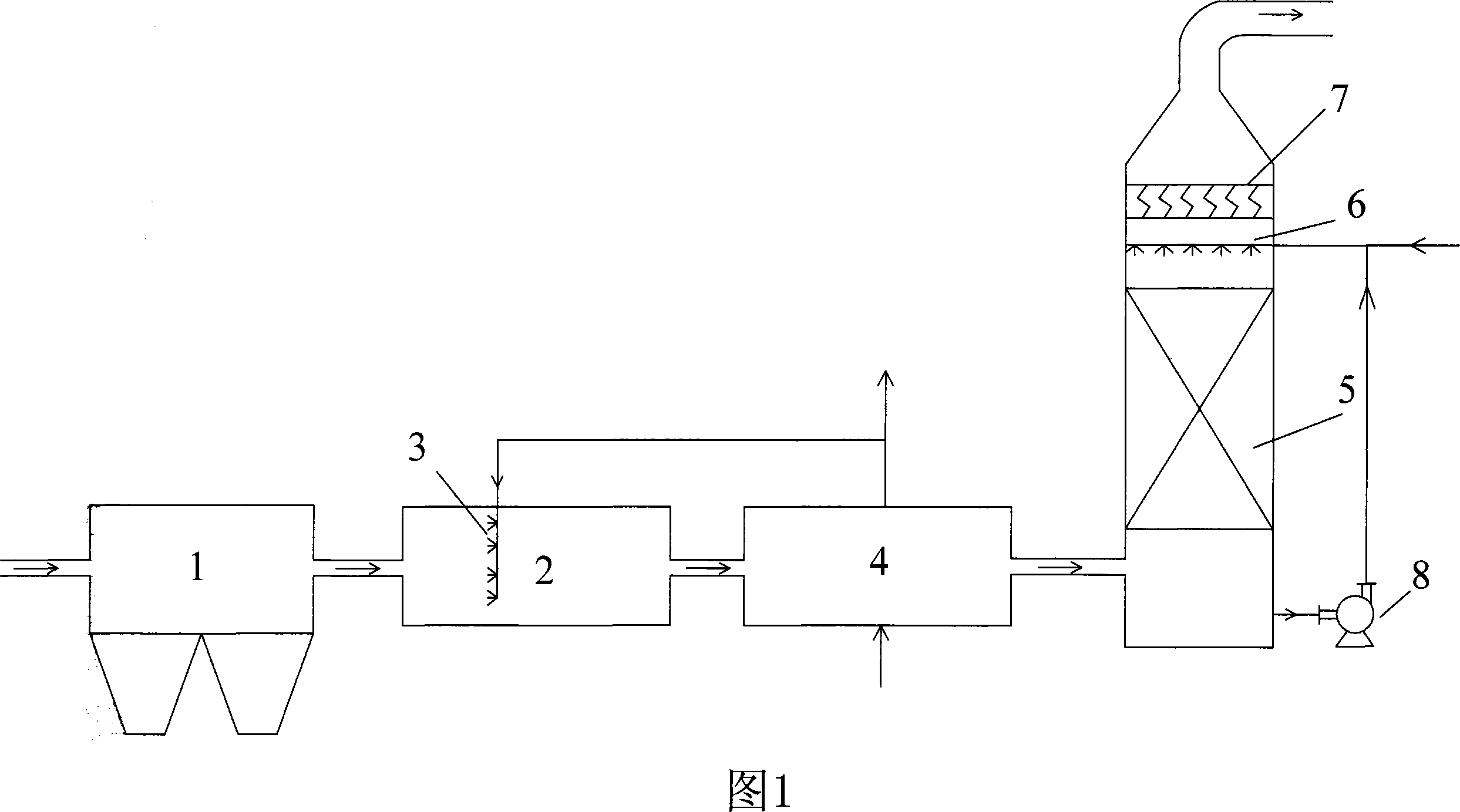

Method of removing PM2.5 and gaseous pollutant using steam phase transition and device thereof

A technology for PM2.5 and pollutants, applied in chemical instruments and methods, separation methods, and the use of liquid separation agents, etc., can solve the problems of large environmental hazards, fine dust particle size, and low capture rate of PM2.5

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

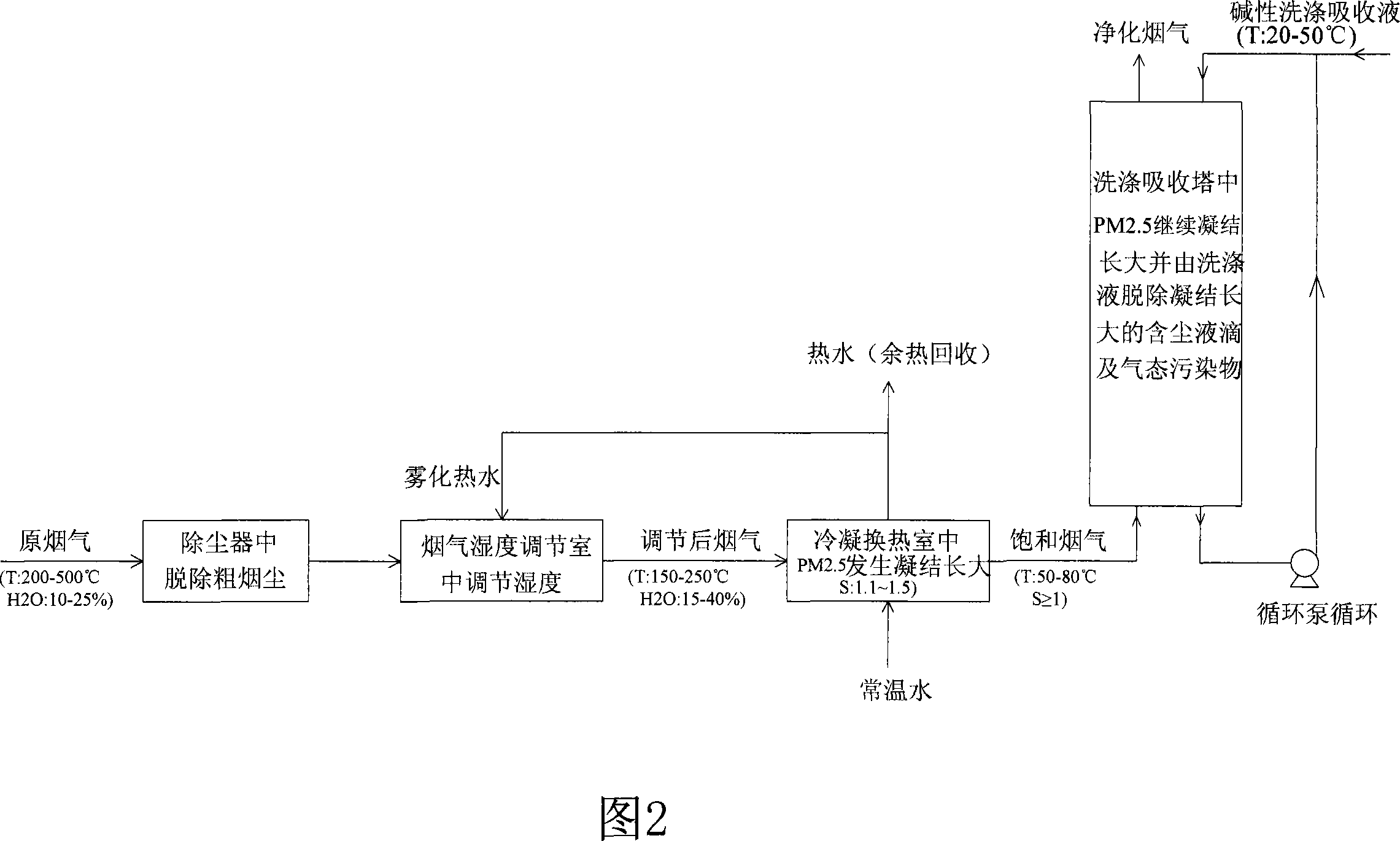

Method used

Image

Examples

Embodiment 1

[0019] The flue gas is produced by a fully automatic oil-fired boiler with a flue gas volume of 65Nm 3 / h, the water vapor content in the flue gas is 12%, the exhaust gas temperature is 282°C, the peak particle size of the smoke dust concentration is 0.07μm, most of which are between 0.03~0.5μm, SO in the flue gas 2 The concentration is 624mg / Nm 3 The wet scrubber adopts a spray tower with a diameter of 150mm and a tower height of 1500mm. The top of the spray tower is equipped with a wire mesh demister, and the washing absorption liquid is Ca(OH) 2 suspension. The dust-containing flue gas produced by the oil-fired boiler directly enters the humidity control room, and is sprayed by the atomizing nozzle into a fine water mist with a temperature of 70°C and a particle size of 20-30μm, and the spraying amount is per Nm 3 The flue gas is 0.01kg. After adjustment, the water vapor content of the outlet flue gas is increased to 24%, and the temperature is 235℃; then it enters the tube-and...

Embodiment 2

[0021] Except for the following changes, the rest is the same as in Example 1.

[0022] The scrubbing absorption tower adopts a swirling plate tower, with 3 swirling plates built-in, a swirling plate demister is installed on the top, and the washing absorption liquid is Na 2 CO 3 Solution, liquid-gas ratio 3.5L / Nm 3 ; After testing, PM 2.5 The mass concentration removal efficiency is 86%, the number concentration removal efficiency is 72%, and the flue gas desulfurization efficiency is 89%.

Embodiment 3

[0024] The flue gas is produced by garbage incineration, and the flue gas volume is 70Nm 3 / h, water vapor content in flue gas is 21%, temperature is 243℃, SO in flue gas 2 The concentrations of HCl, HF are 729mg / Nm respectively 3 ,876mg / Nm 3 , 21mg / Nm 3 , The peak particle size of the dust concentration at the outlet of the dust collector is 0.7μm, and the number concentration is 10 6 Pcs / cm 3 ; The scrubbing absorption tower is a cyclone plate tower with a tower diameter of 150mm and a tower height of 1500mm, with 3 built-in cyclone plates, and a cyclone plate demister on the top. The scrubbing absorption liquid is Na 2 CO 3 Solution. After the waste incineration flue gas is removed by the cyclone dust collector, it enters the humidity control room, and is sprayed into a fine water mist with a temperature of 65°C and a particle size of 20-30μm from the atomizing nozzle, and the spraying amount is per Nm 3 The flue gas is 0.008kg. After adjustment, the water vapor content in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com