High-temperature low-tar biomass gasifier

A gasification device and low-tar technology, applied in cracking, petroleum industry, catalytic cracking, etc., can solve problems such as the failure of subsequent unit equipment to operate normally, reduce the economic efficiency of biomass energy utilization, and increase the cost of biomass gasification. Achieve the effects of prolonging the residence time, reducing the temperature gradient in the furnace, and enhancing the gasification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

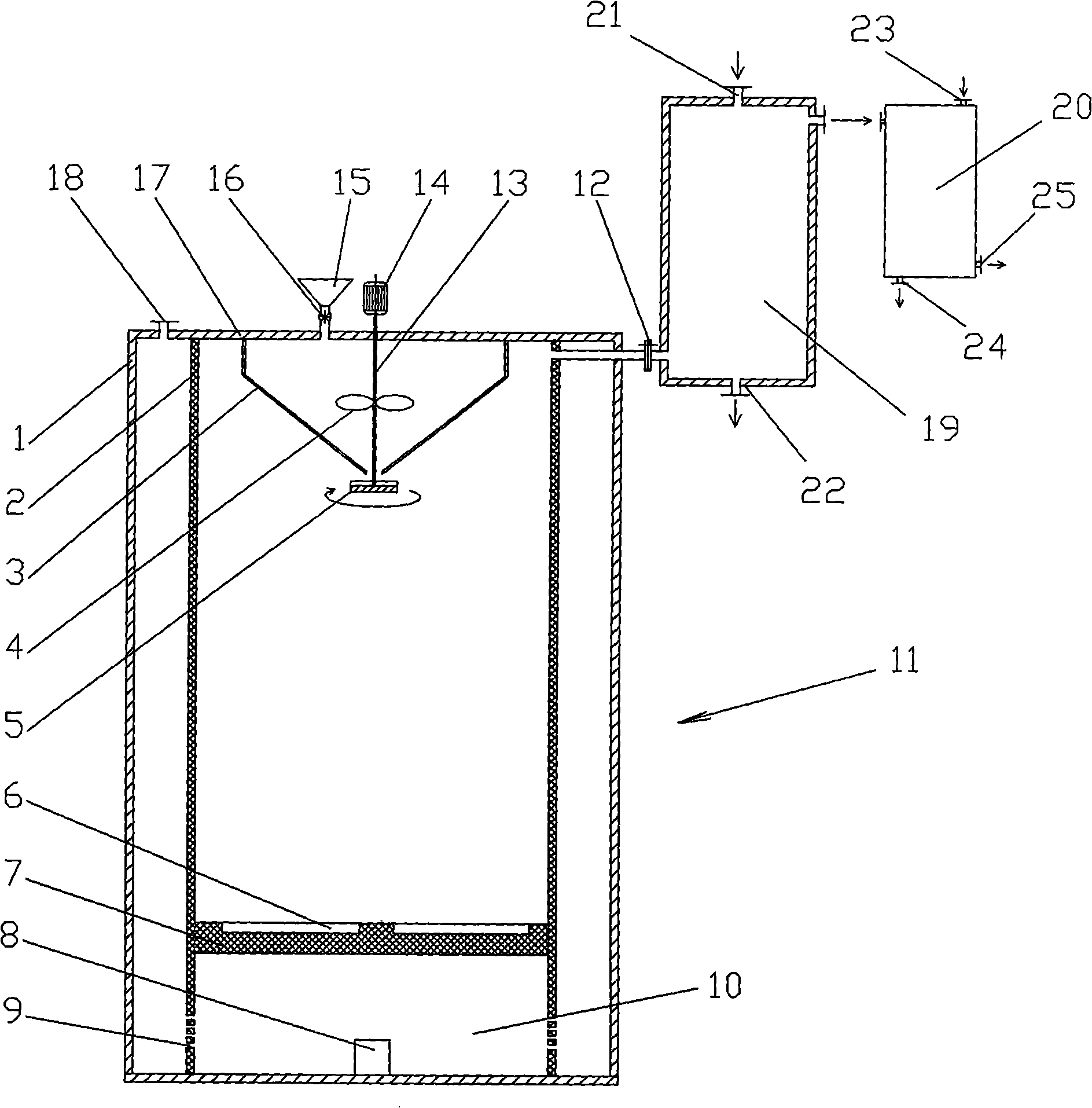

[0026] see figure 1 , feeder 15, gasifier 11, tar catalytic cracking reaction cylinder 19 and heat exchanger 20 are sequentially connected, wherein, the connecting pipe 12 connecting gasification furnace 11 and tar catalytic cracking reaction cylinder 19 is connected with the interior of gasification furnace 11 Tube 2 upper ends communicate.

[0027] The feeder 15 is fixed on the furnace roof 17, and a star-shaped sealing rotary valve 16 is arranged on the pipeline at the lower end of the feeder, and the outlet of the star-shaped sealing rotary valve 16 communicates with the preheating hopper 3 .

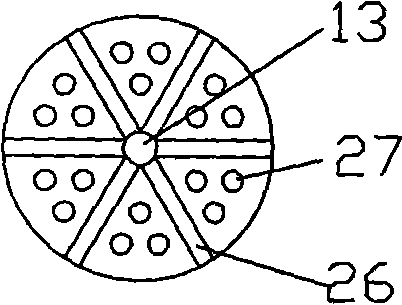

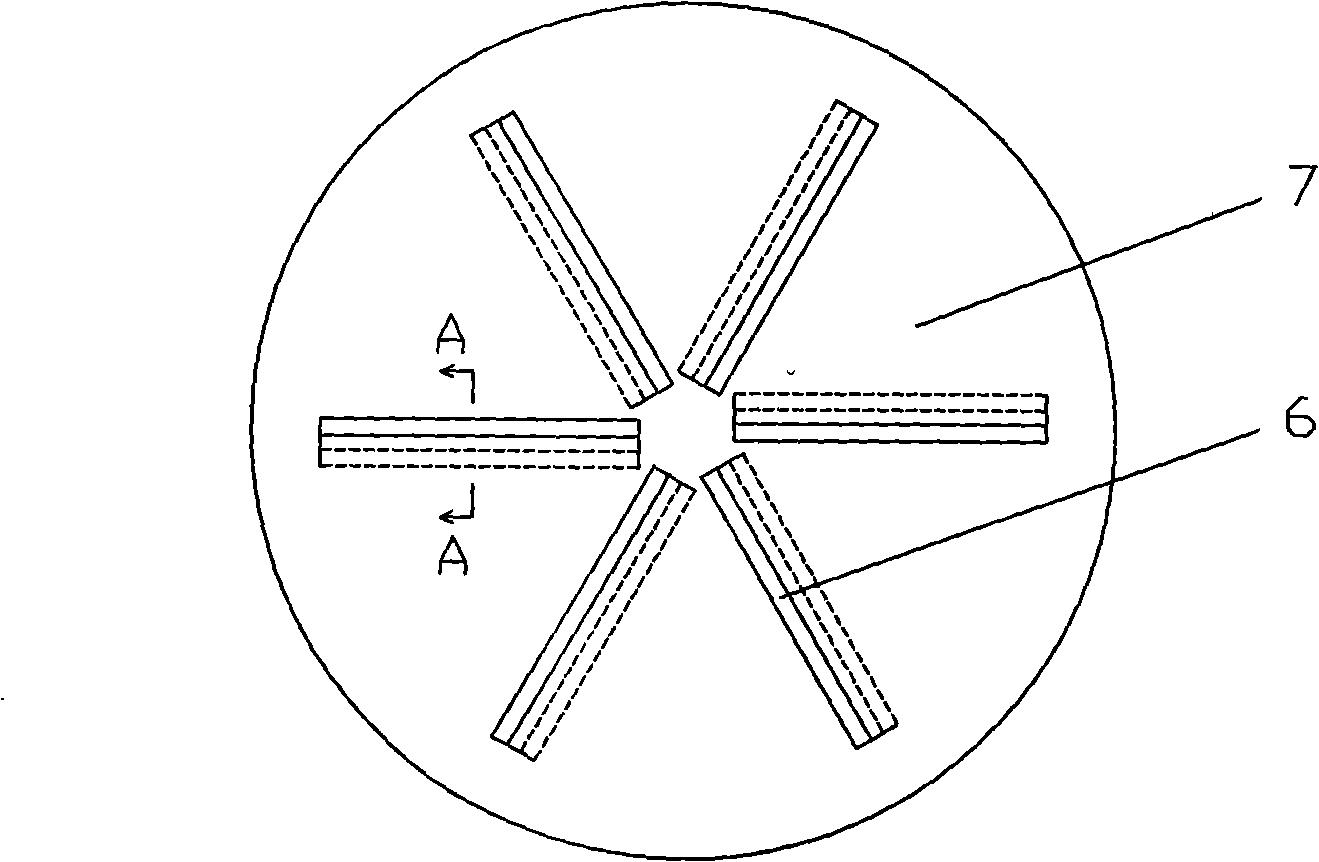

[0028] The gasification furnace 11 is set as a sleeve structure by the inner cylinder 2 and the outer cylinder 1, and an annular cavity is formed therebetween; in the inner cylinder 2, a preheating furnace connected to the feeder 15 and connected to the feeder 15 is installed. The hopper 3 is provided with a rotatable distribution grid 5 below the outlet of the preheating material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com