Internal-combustion heating type biomass gasification furnace

A biomass and gasification furnace technology, applied in solid heating fuel, lighting and heating equipment, coking ovens, etc., can solve the problems affecting the normal operation of the gasification furnace, gas transmission, storage and utilization, affecting the normal operation of the blower, and the calorific value of gas Low-level problems, to achieve the effects of increasing biomass gasification rate and gas calorific value, reducing ash production and processing difficulty, and high tar catalytic cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

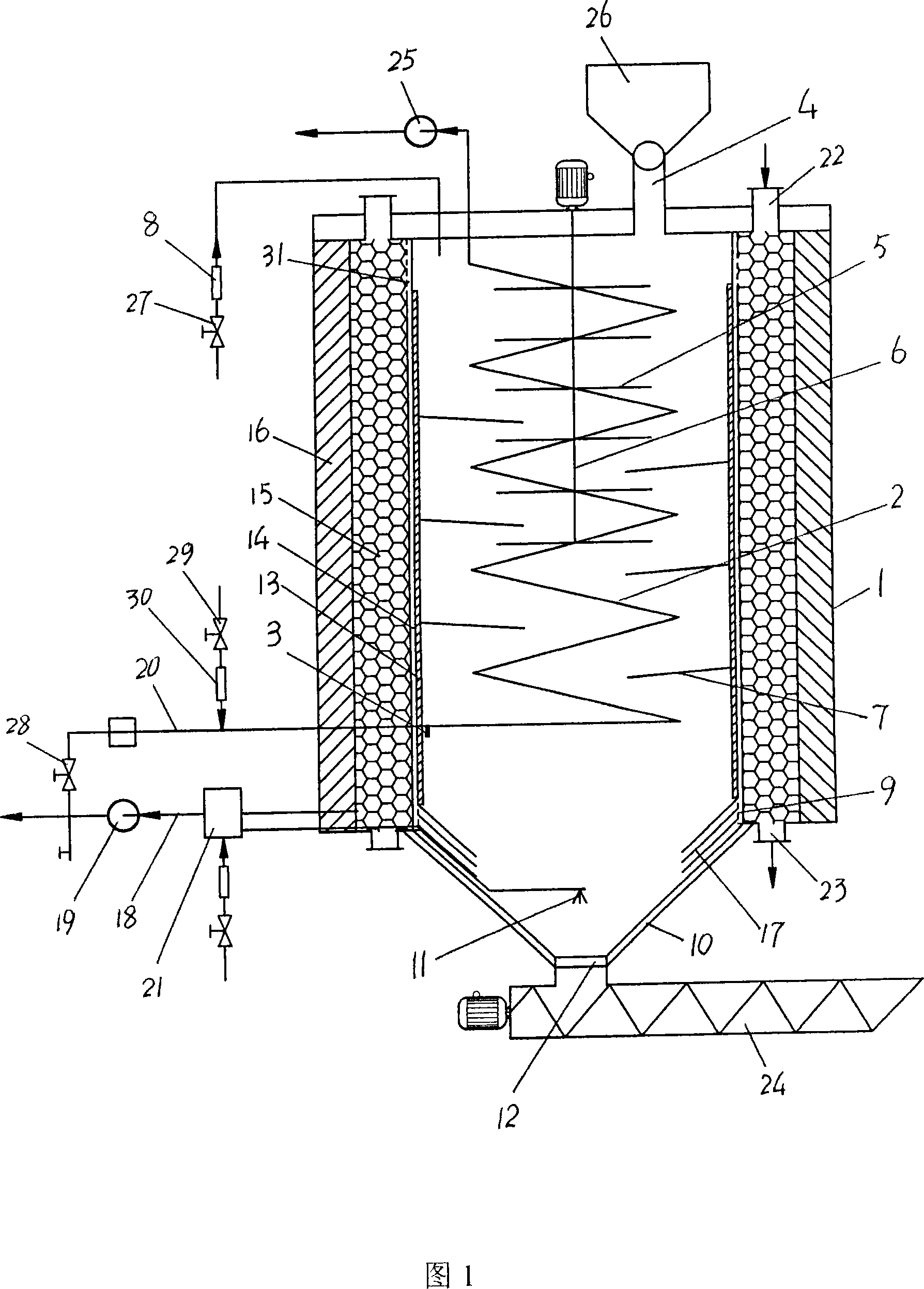

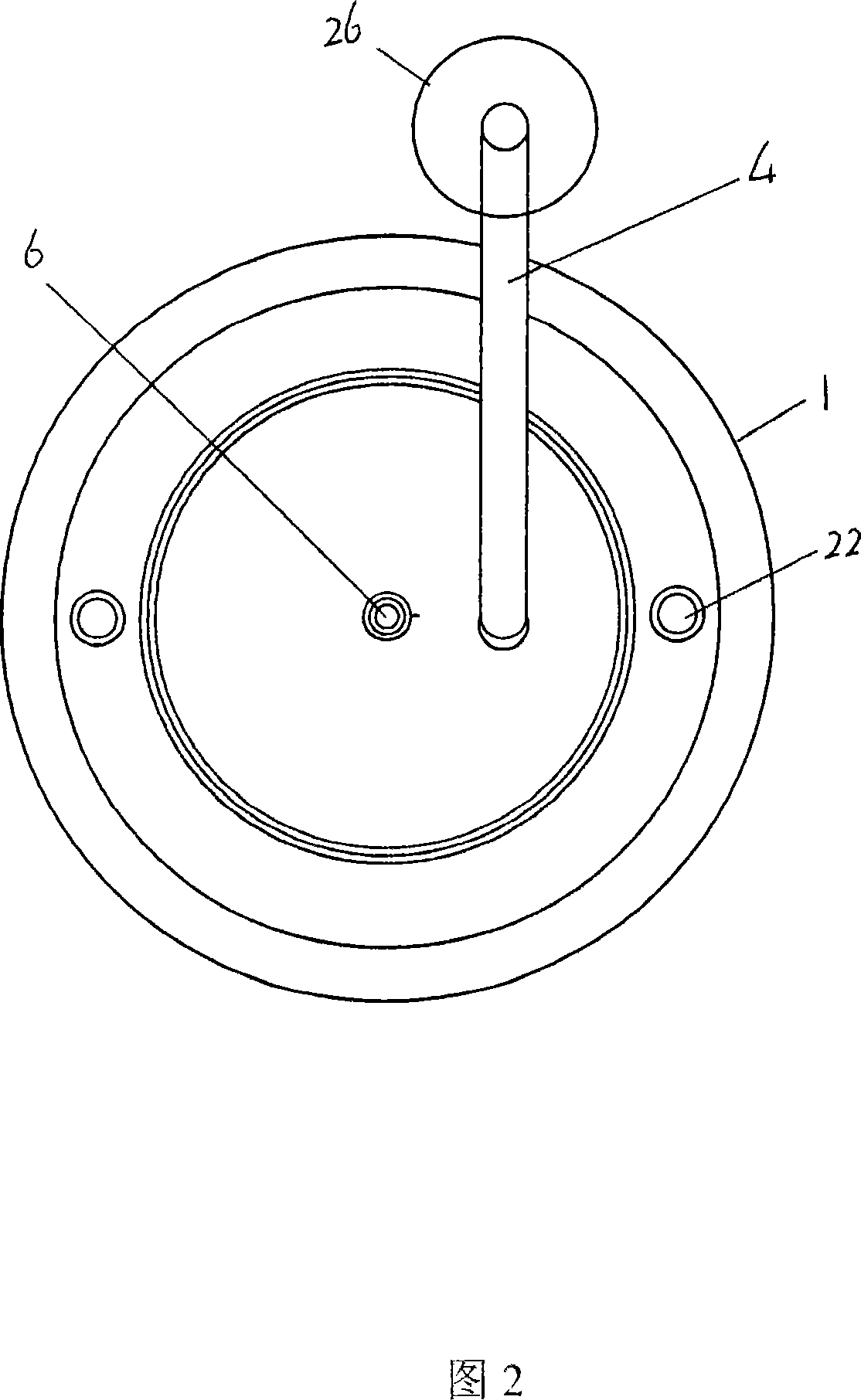

[0034] Referring to Fig. 1 and Fig. 2, the present embodiment adopts a cylindrical furnace body 1, and inside the cylindrical furnace body 1, a serpentine internal combustion pipeline 2 is arranged, and the entrance of the serpentine internal combustion pipeline 2 is located at the bottom of the cylindrical furnace body 1. The lower part, its outlet extends from the top of the cylindrical furnace body 1 to the outside of the furnace body, and the igniter 3 is located at the entrance of the internal combustion pipeline 2;

[0035] Above the cylindrical furnace body 1, a screw feed mechanism 4 is arranged, and the screw feed port is located at the top eccentric position of the cylindrical furnace body 1, and on the central axis position of the cylindrical furnace body 1, a The stirring shaft 6 of the stirring blade 5 is provided with a multi-layer baffle plate 7 along the circumferential surface of the side wall on the inner side wall of the cylindrical furnace body 1;

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com