Integration biomass gasification stove catalytic splitting process and device thereof

A catalytic cracking and gasifier technology, which is used in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of low gas temperature, unfavorable tar cracking rate, unfavorable normal gas production process of the gasifier, etc., and achieves convenient operation. , simple structure, the effect of promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiments:

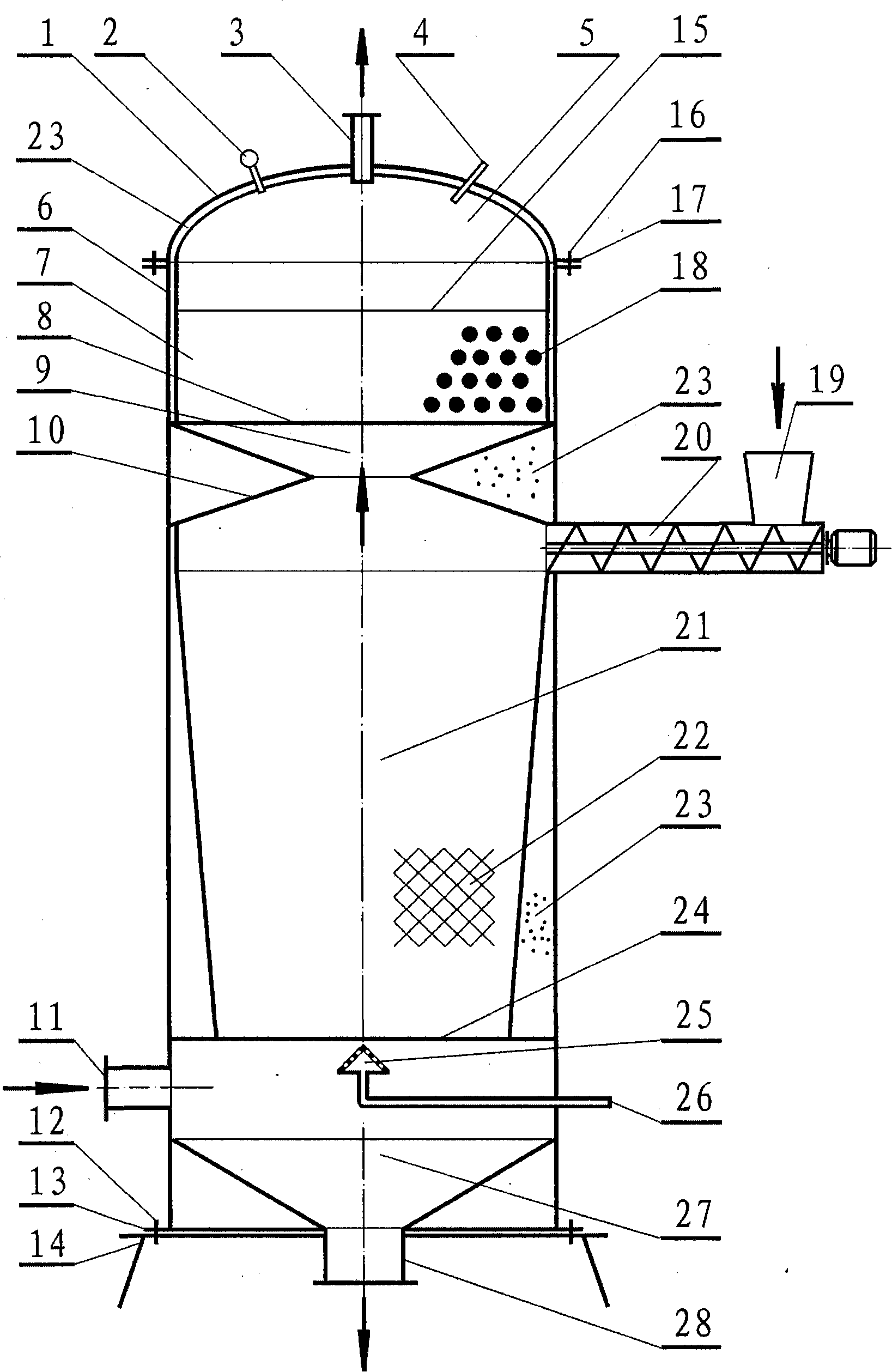

[0025] Integrated biomass gasifier catalytic cracking method: the biomass fuel (22) enters the combustion chamber (21) from the feed port (19) through the screw input device (20), ignites the biomass fuel (22) to start burning, and A large amount of combustible gas is generated in the combustion chamber (21) from the air intake pipe (11), and the burning biomass fuel (22) produces a large amount of combustible gas. As the temperature in the combustion chamber (21) continues to rise, the combustible gas rises to X After a short stay in the fuel gas buffer chamber (9), it enters the tar catalytic cracking chamber (7). The biomass gasifier catalyst (18) in the tar catalytic cracking chamber (7) fully performs the tar treatment on the combustible gas. Catalytic cracking and purification filtration, pure combustible gas enters the gas purification room (5) and is discharged from the outlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com