Device and method for producing clean fuel gas and biomass charcoal through continuous biomass carbonization

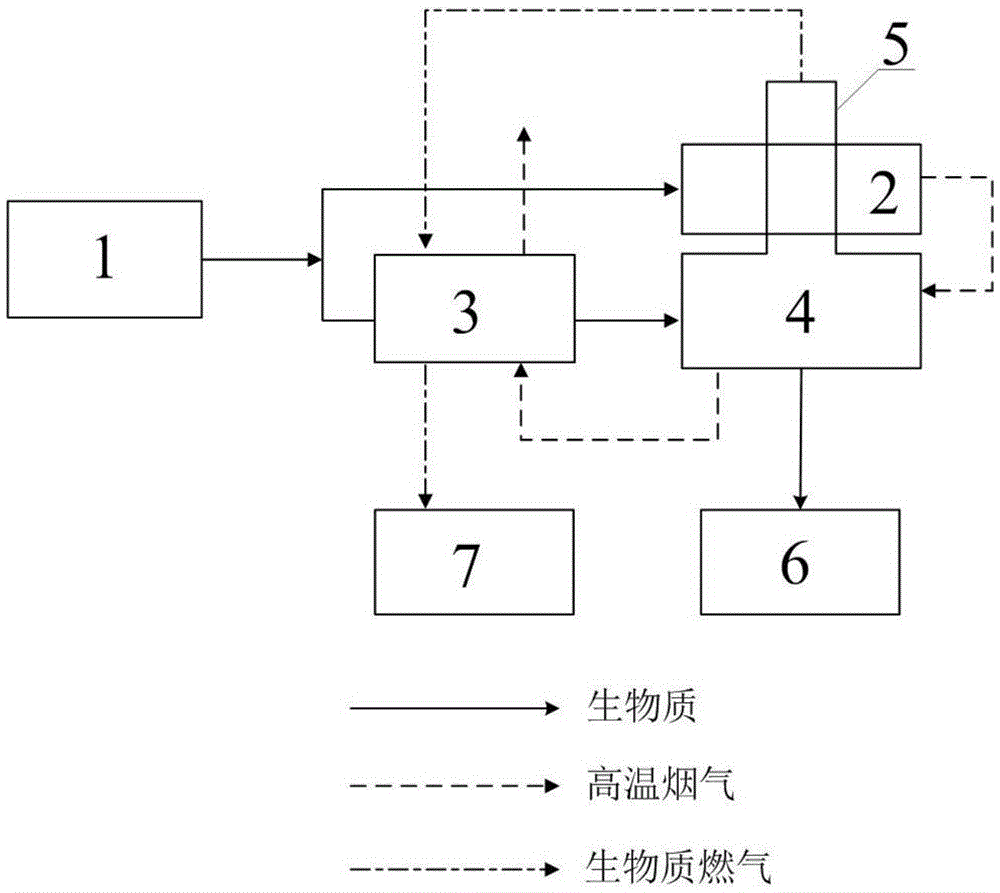

A biomass charcoal and biomass technology, applied in the field of efficient and clean utilization of biomass, can solve the problems of single structure, high tar content and ineffective utilization, etc., and achieve the effects of short process flow, flexible and reliable production control, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

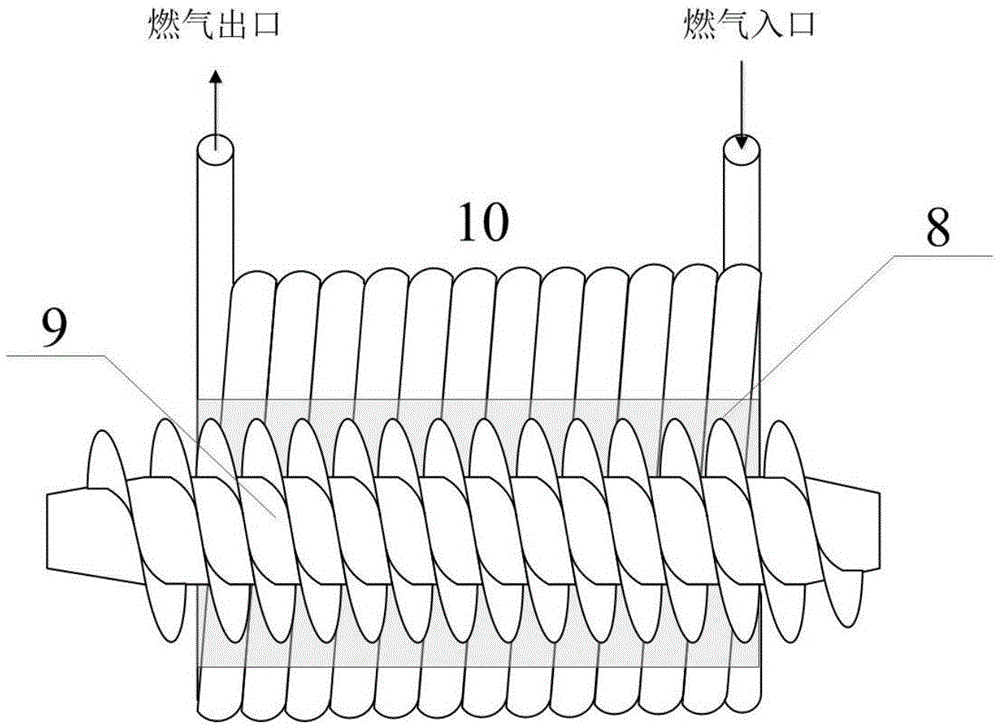

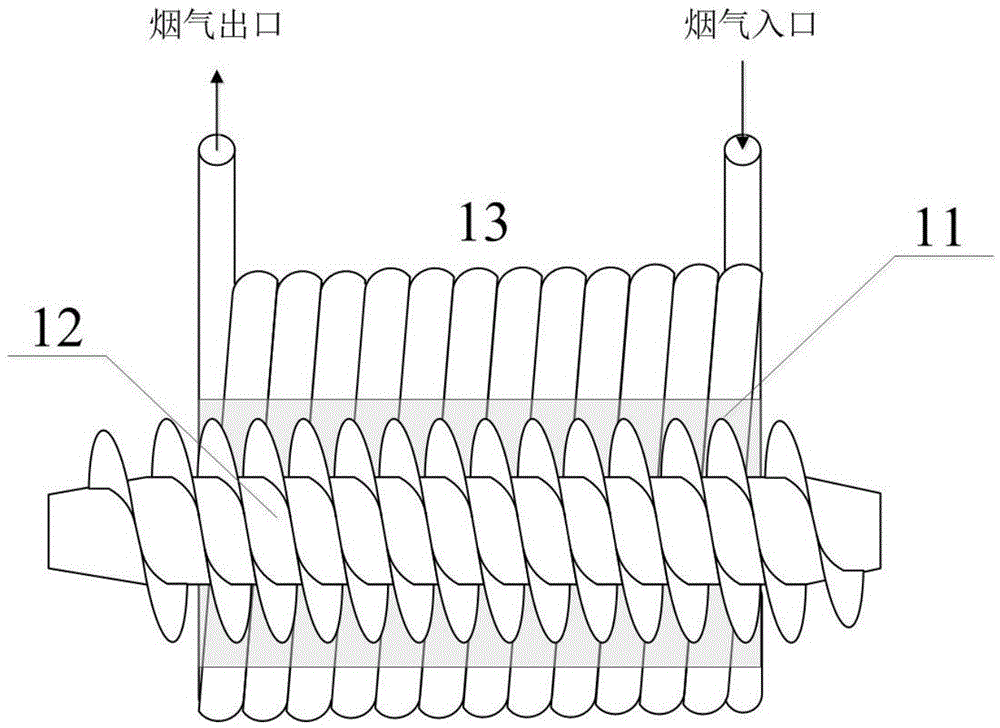

[0037] Using molded rice straw as raw material, the device and method disclosed in the invention are used to continuously carbonize rice straw and catalytically crack tar in gas to produce clean gas and biomass charcoal. Part of the formed rice straw is transported to the biomass boiler for combustion through the belt conveyor. The furnace temperature of the biomass boiler is 1100°C, and a part of the formed rice straw is transported to the biomass drying unit through the belt conveyor. The temperature of the high-temperature flue gas produced by the combustion of the biomass boiler is 900°C. The high-temperature flue gas provides heat for the carbonization of biomass through the flue gas pipe on the outer wall of the carbonization furnace. The central temperature of the biomass carbonization furnace is 580°C. The tar in the gas produced by biomass carbonization undergoes catalytic cracking reaction in the reactor built in the high temperature zone of the biomass boiler, and th...

Embodiment 2

[0039]Using corn stalks as raw materials, the device and method disclosed in the invention are used to continuously carbonize corn stalks and catalytically crack tar in gas to produce clean gas and biomass charcoal. A part of the corn stalks is transported to the biomass boiler for combustion by the belt conveyor. The furnace temperature of the biomass boiler is 1040°C, and a part of the corn stalks are transported to the biomass drying unit by the belt conveyor. The temperature of the high-temperature flue gas produced by the combustion of the biomass boiler is 820°C. The high-temperature flue gas provides heat for the carbonization of biomass through the flue gas pipe on the outer wall of the carbonization furnace. The central temperature of the biomass carbonization furnace is 520°C. The tar in the gas produced by biomass carbonization undergoes catalytic cracking reaction in the reactor built in the high temperature zone of the biomass boiler, and the temperature of the cra...

Embodiment 3

[0041] Using wood chips as raw materials, the device and method disclosed by the invention are used to carry out continuous carbonization of wood chips and catalytic cracking of tar in gas to produce clean gas and biomass charcoal. Part of the sawdust is transported to the biomass boiler for combustion through the belt conveyor. The furnace temperature of the biomass boiler is 1150°C, and part of the sawdust is transported to the biomass carbonization unit through the belt conveyor. The temperature of the high-temperature flue gas produced by the combustion of the biomass boiler is 970°C. The high-temperature flue gas provides heat for the carbonization of biomass through the flue gas pipe on the outer wall of the carbonization furnace. The central temperature of the biomass carbonization furnace is 610°C. The tar in the gas produced by biomass carbonization undergoes catalytic cracking reaction in the reactor built in the high temperature zone of the biomass boiler, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com