Tobacco stem waste gasification system device and production technology thereof

A gasification system and production process technology, applied in the field of tobacco stem waste gasification system device and its production process, can solve the problems of impure oxygen content of gas, waste of gas, short running time, etc. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

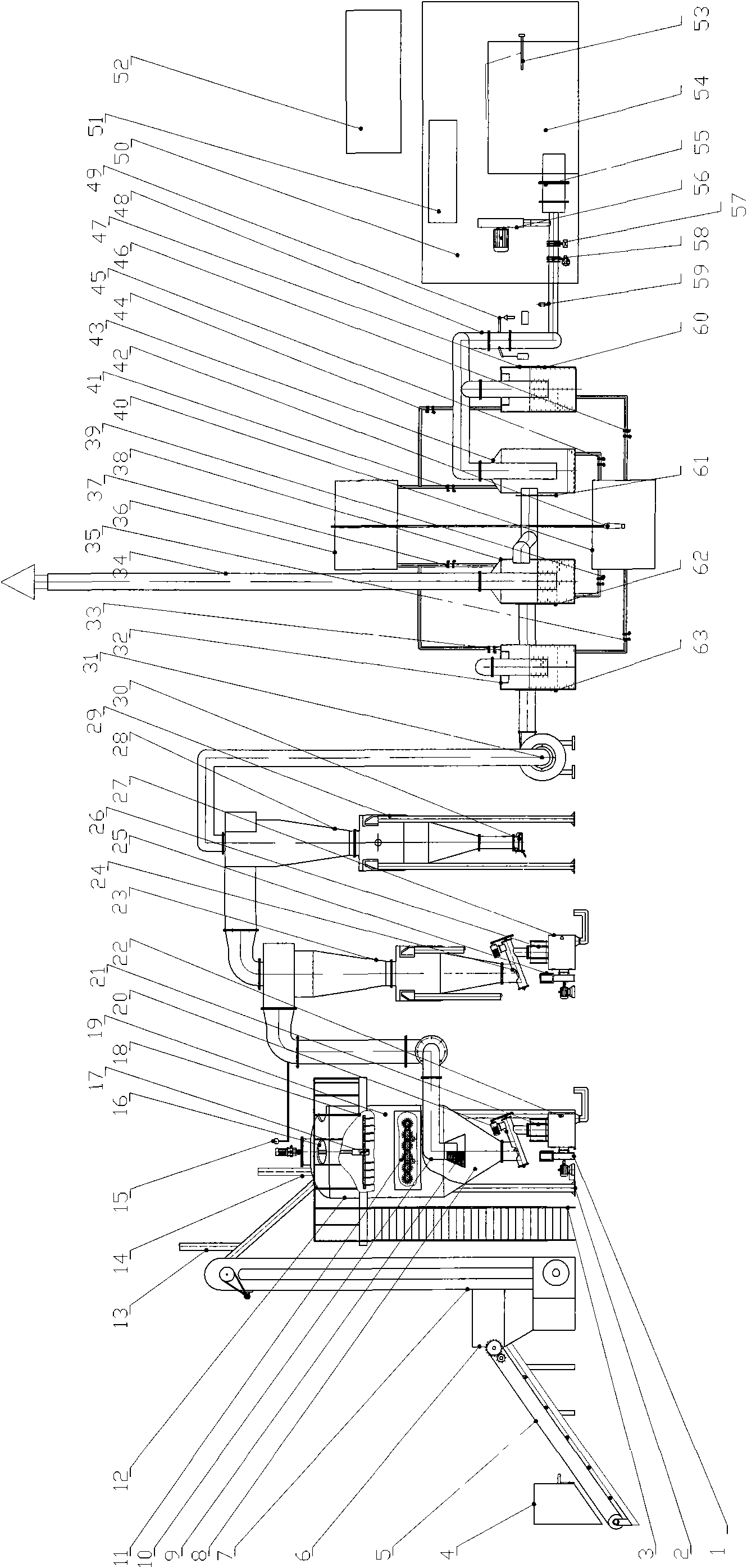

[0082] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

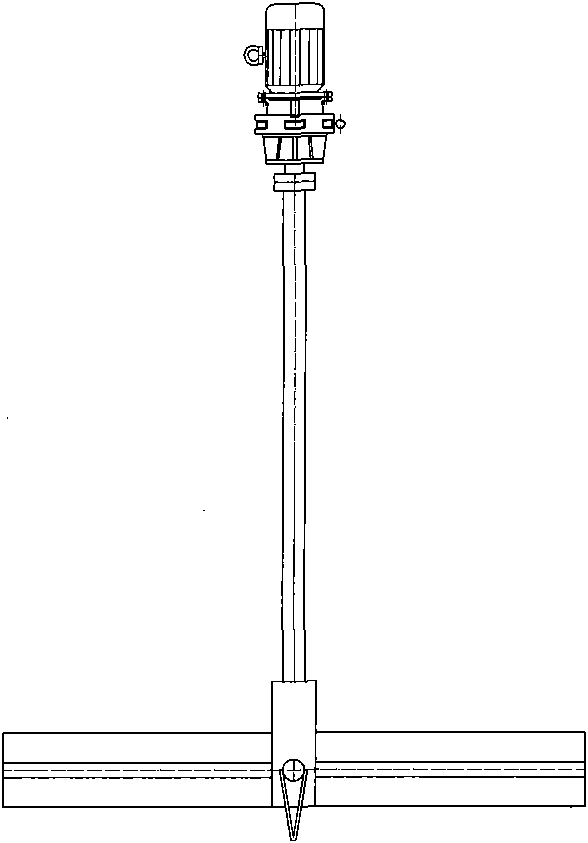

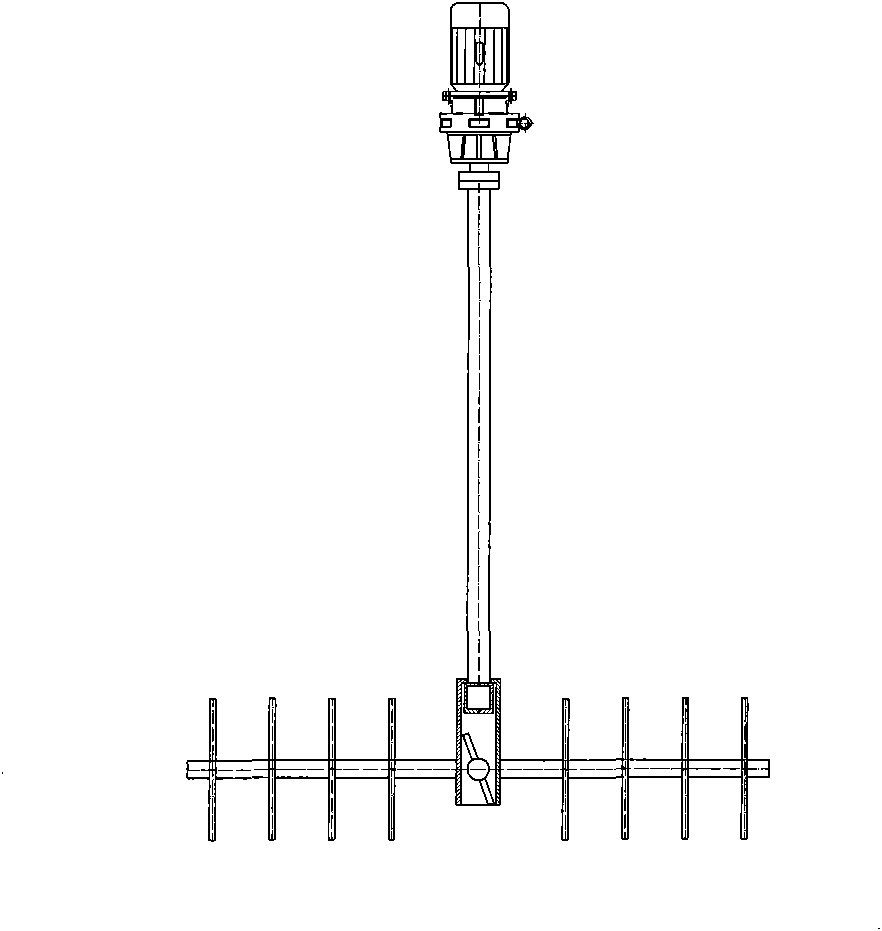

[0083] A tobacco stem waste gasification system device, such as Figure 1 to Figure 12 As shown, the main structure of the system device is a set of interrelated equipment, and the arrangement sequence starts from the raw material bin 4 of the electric belt conveyor, including the raw material bin 4, the lower end of the raw material bin 4 is equipped with a belt conveyor 5, and the end of the belt conveyor 5 A feeder 7 is provided, and the end of the belt conveyor 5 is mounted on the top of the feeder hopper 6. The outlet of the feeder 7 is connected to a gasifier 12 through a pipeline, and a fuel preheating pipe 13 is installed above the pipeline. The upper end of the feed inlet of the gasifier 12 is equipped with a safety release pipe 14, the other three sides of the top of the gasifier 12 are provided with a gasifier operating port 16, and the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com