Biomass gasifier and gas preparation method thereof

A gasification device and biomass technology, which is applied in the production of combustible gas, combined combustion mitigation, and fuel pre-dry distillation, etc., can solve the problems of tar blockage in gas pipelines, low calorific value of gas, separation of tar and water, etc. The effect of increasing the calorific value of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

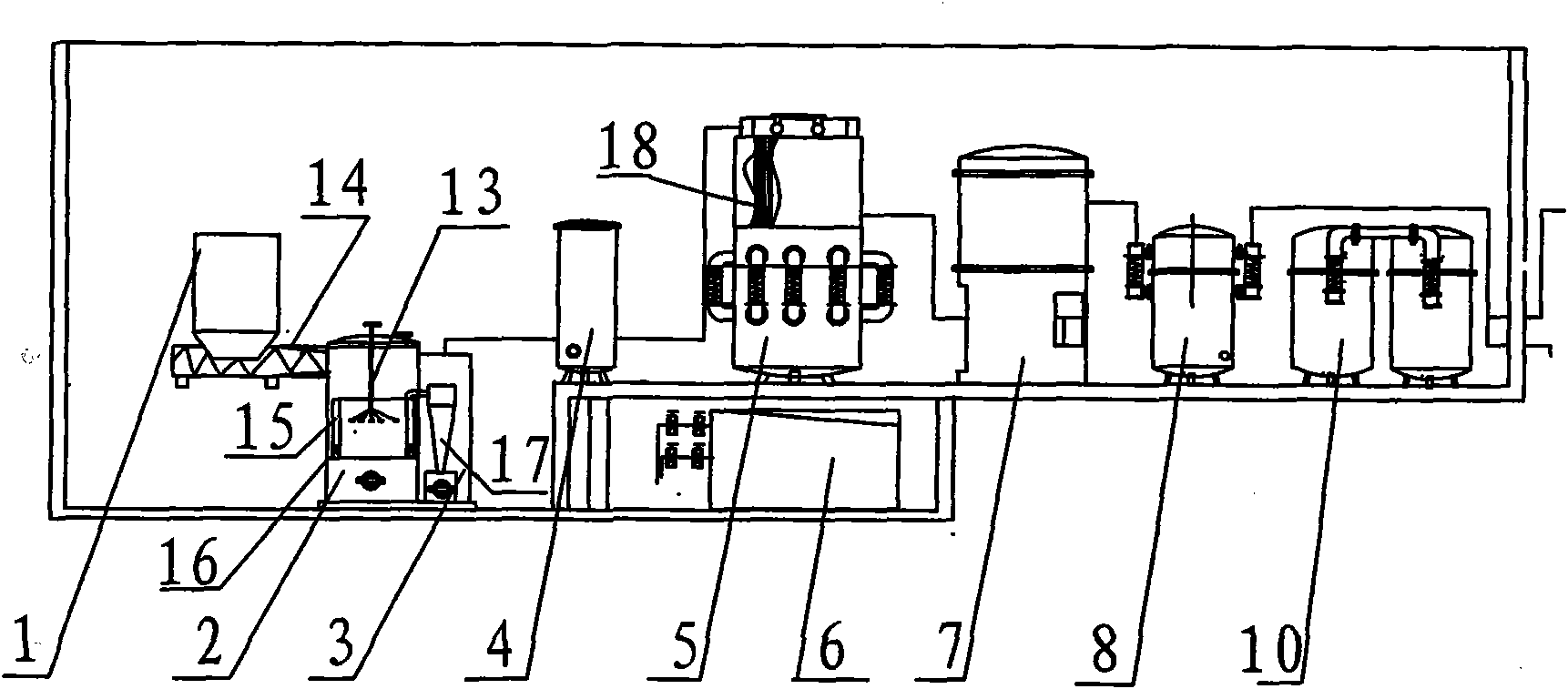

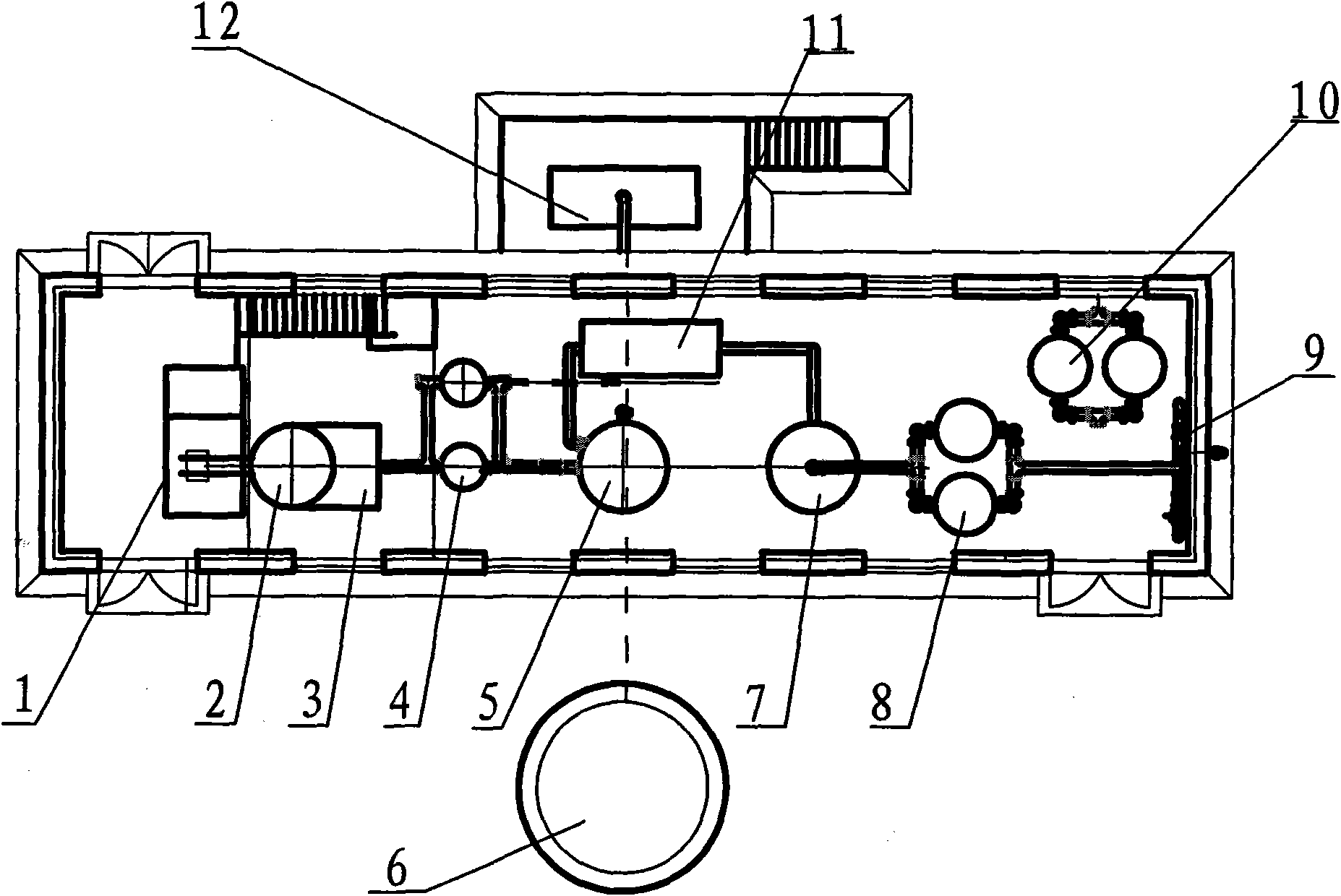

[0017] Biomass gasification device, including feeding bin 1 arranged above the main furnace, conical screw feeder 14 arranged below the feeding bin, main furnace 2 connected to the discharge port of the conical screw feeder, the main furnace passes through the gas pipeline Auxiliary furnace 3, primary filter 4, cooler 5, vacuum pump 11, desulfurizer 7, fine filter 8, control system 9, coke filter 10 for further filtering tar and wood wax liquid, coke accumulation tank 12 and cooling Fire pool 6. The feed port of the conical screw feeder 14 is closed and connected with the discharge port of the upper bin 1 , and the discharge port of the conical screw feeder 14 is closed and connected with the feed port of the main furnace 2 . The main furnace 2 is provided with a feeder 13 and a high-temperature cracker 15, and the feeder 13 can not only rotate but also move up and down; the high-temperature cracker 15 is a barrel-shaped jacket, and the jacket layer and the bottom are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com