Normal pressure non-phenol method for fixed-bed gas producer

The technology of a gas generator and a fixed bed is applied in the field of normal pressure and phenol-free, which can solve the problems of complicated purification and cooling process, increase the difficulty of gas treatment, and high moisture content of the gas, and achieve the reduction of the moisture content, the reduction of heat emission, and the high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

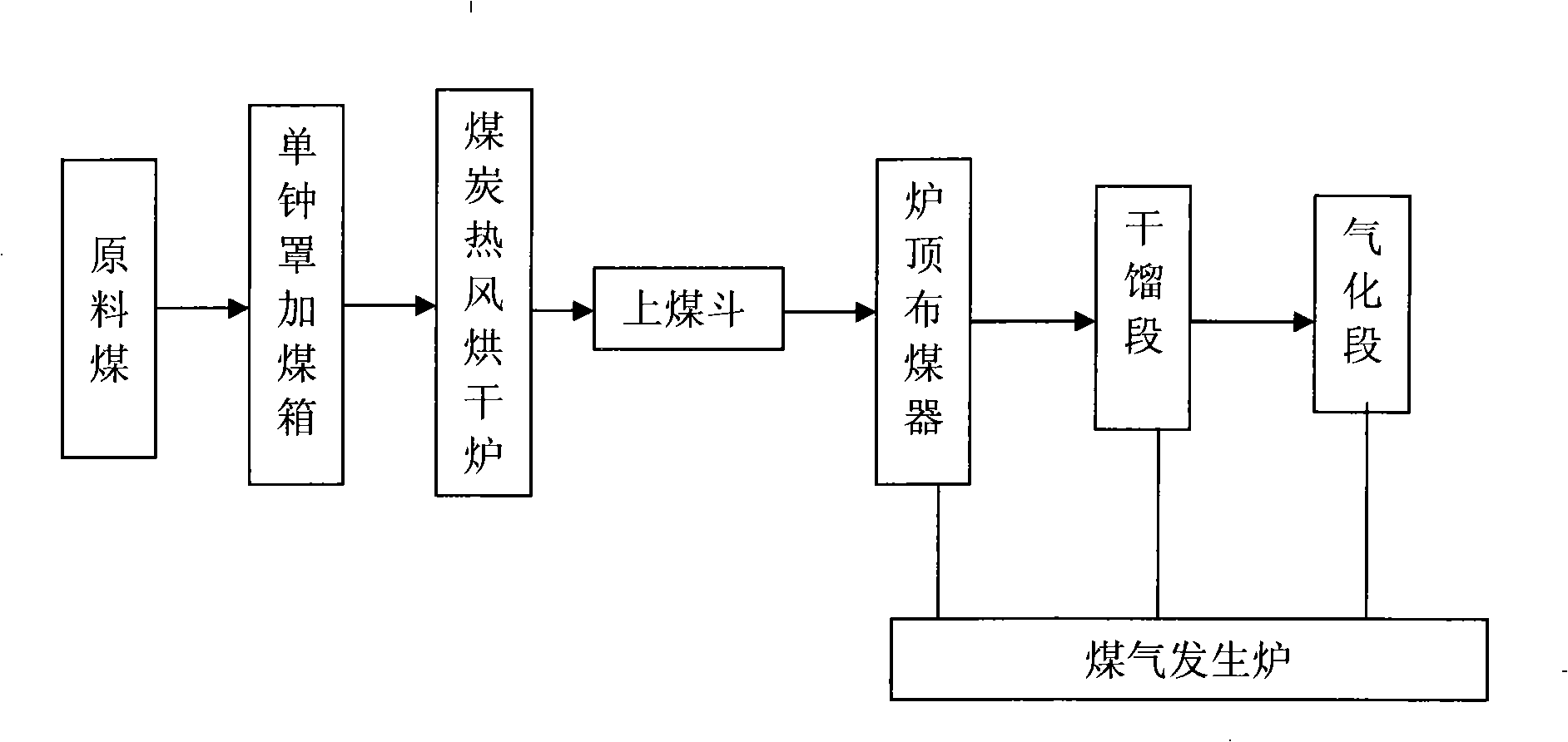

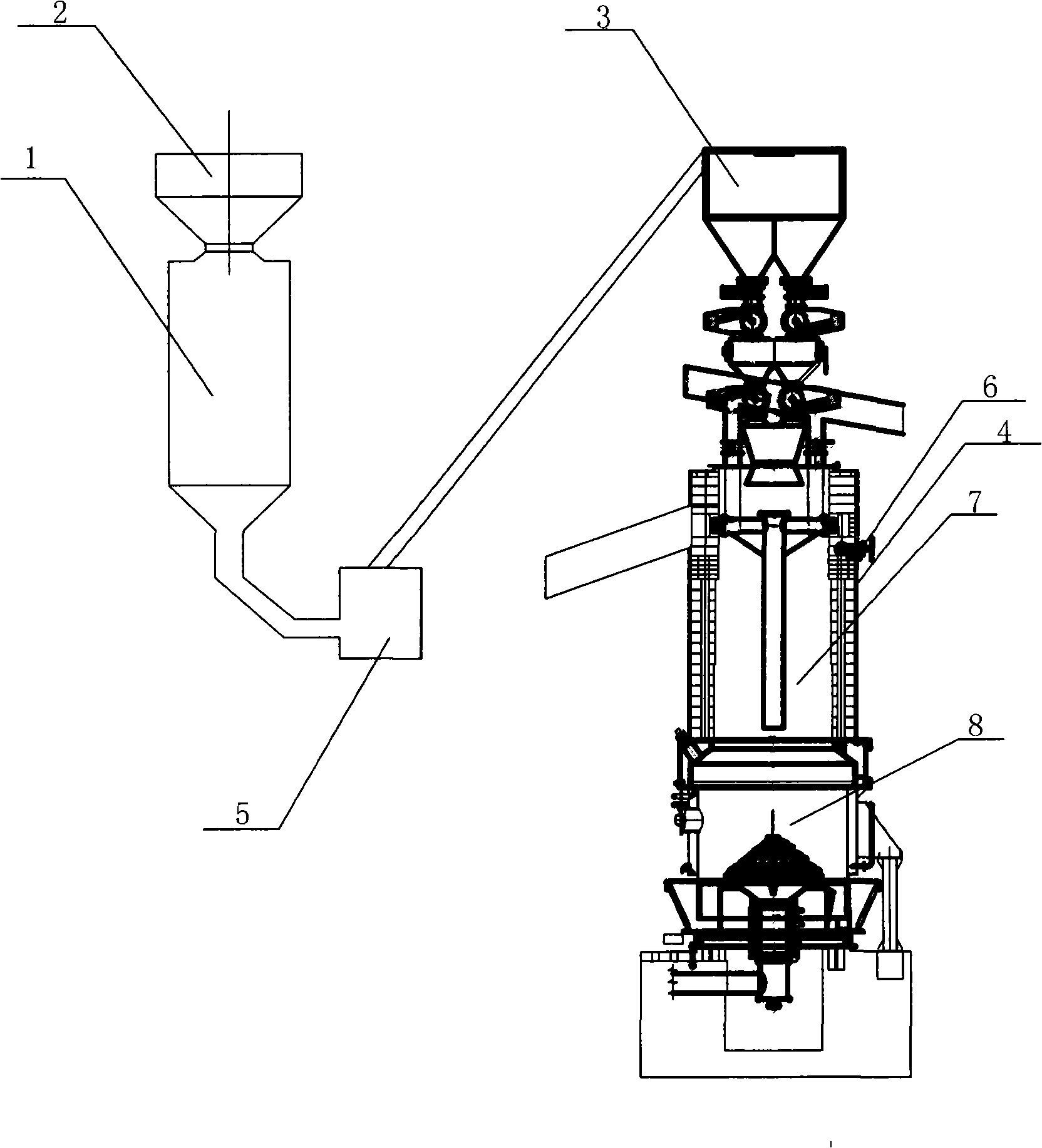

[0023] In order to better understand the present invention, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] (1) Drying of raw coal

[0025] The coal loading trolley loads the raw coal into the single bell jar coaling box 2, and then the raw coal enters the coal hot air drying furnace 1, and the raw coal in the coal hot air drying furnace 1 is released into the super-speed guide exchanger in the gas purification and cooling process. The heated section is contacted with air at 50-300°C, and is slowly heated during the descent process. When it reaches about 110°C, the surface moisture and absorbed moisture in the coal are completely removed, and only a very small part of the combined moisture remains. The dried coal finally falls out from the lower coal outlet and enters the upper coal hopper 5.

[0026] (2) dry distillation process

[0027] The dried raw coal is fed from the upper coal h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com