Preparation method for hydrogen-rich gas through steam gasification of solid organic matter

A technology for solid organic matter and solid products, applied in the manufacture of combustible gases, gasification processes, gasification catalysts, etc., can solve the problem of the difficulty in realizing the optimal operation of pyrolysis reactors and gasification reactors, and the types and quantities cannot be independently controlled And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

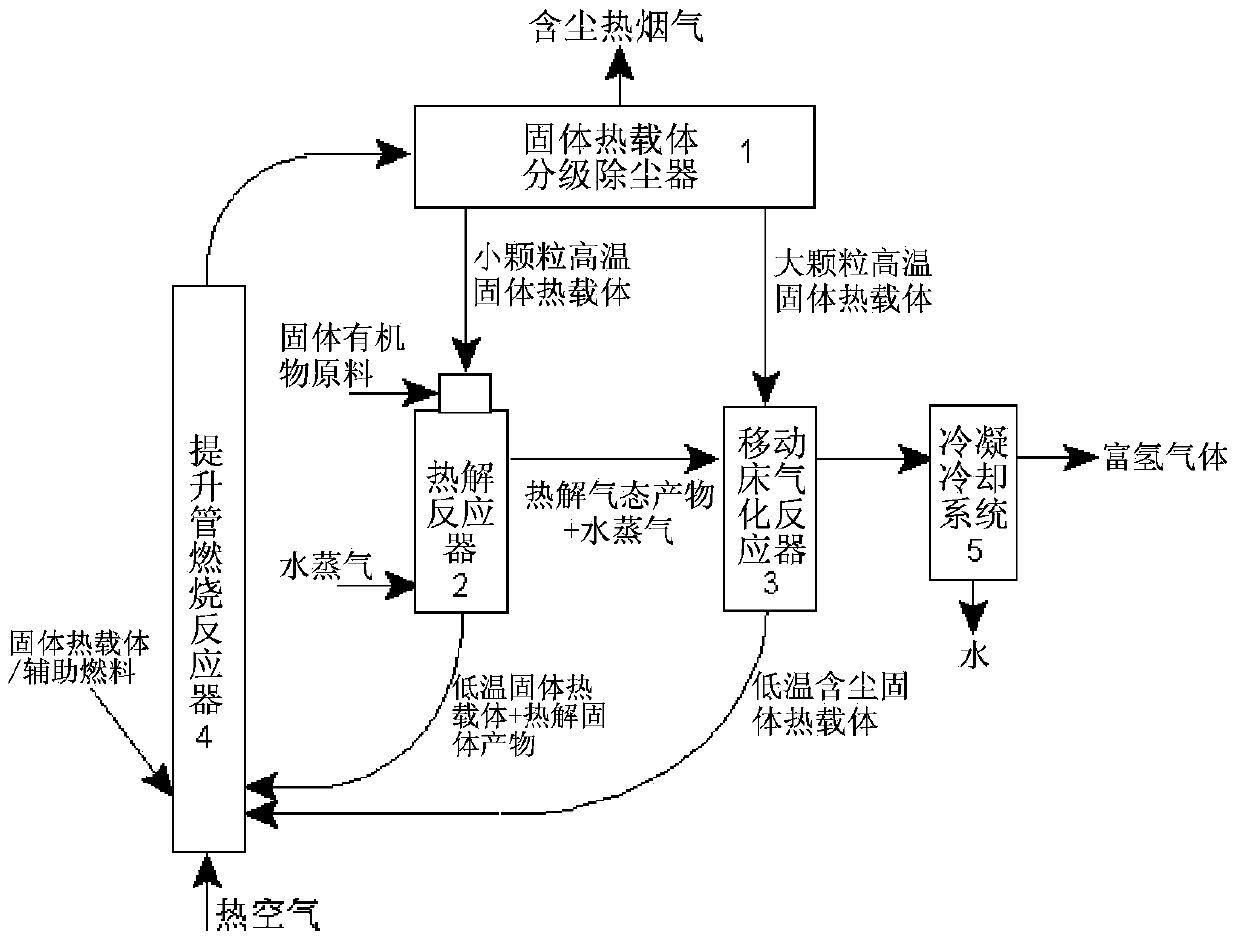

[0055] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0056] The rapid co-gasification of white pine wood chips and lignite is carried out in the experimental system with a raw material handling capacity of 1kg / h. The operating principle of the experimental system is the same as figure 1 . The air-drying basis moisture, air-drying basis volatile matter and particle size of the first raw material white pine sawdust and the second raw material lignite are 5.0%, 77.7%, less than 2mm and 27.9%, 35.1%, less than 1.2mm respectively. Before the experiment, the raw materials were dried in an oven at 105-110°C for 3 hours. Olivine or olivine-supported nickel catalyst particles with a particle size of 0.2-1.2 mm are used as the circulating solid heat carrier.

[0057] The dried white pine sawdust and lignite are quantitatively fed into the secondary screw feeder from their resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com