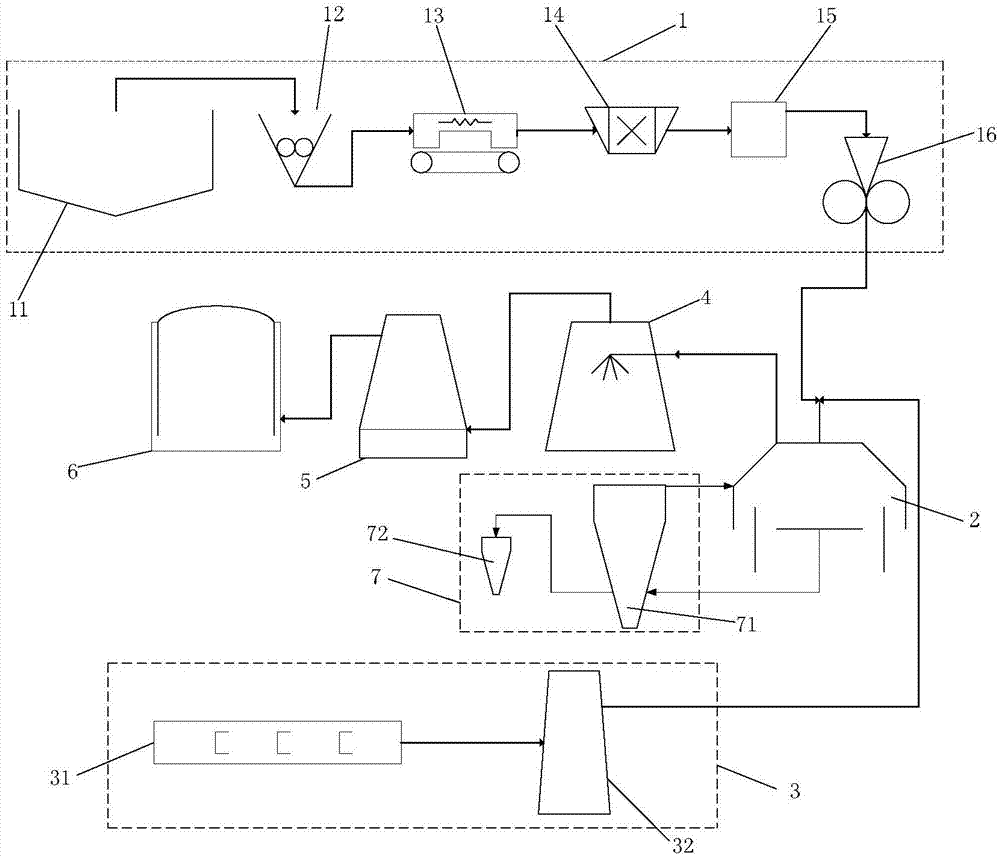

Garbage pyrolysis system and method

A technology of waste and pyrolysis, which is applied in the combination of gasification process, petroleum industry, fuel pre-dry distillation, etc., can solve problems such as blockage, and achieve the effect of reducing energy consumption, reducing energy consumption of waste gasification, and saving process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

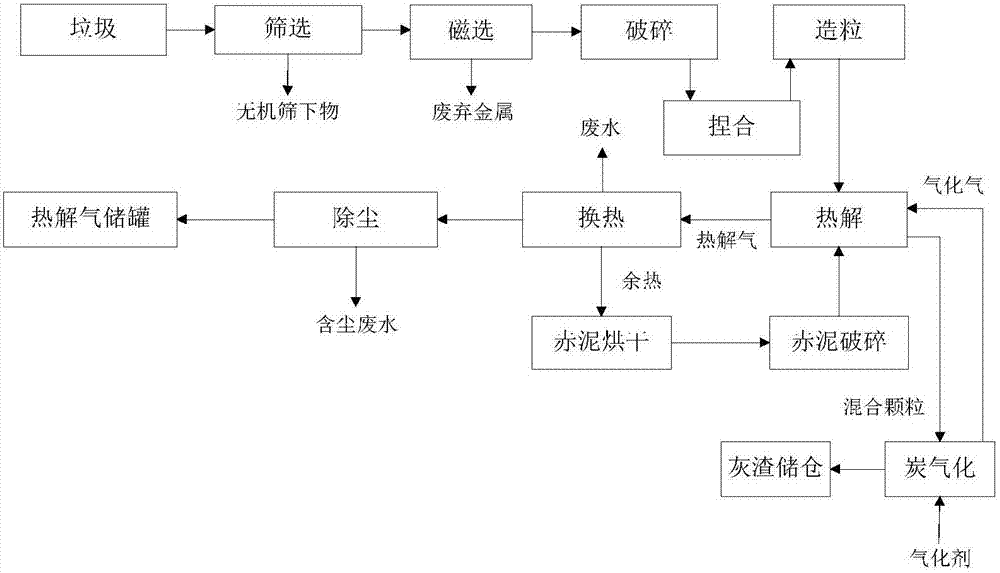

[0082] 1. The garbage is sent to the trommel screen for screening, and the slag, sand and other inorganic substances in the garbage are screened out from the sieve holes to obtain the screened garbage.

[0083] 2. Send the screened garbage to the magnetic separator to obtain magnetically separated garbage after metal removal.

[0084] 3. Send the magnetically separated garbage into the crusher, and obtain broken garbage after crushing. The particle size of the broken garbage is 8mm.

[0085] 4. Mix the crushed garbage and additives in a kneader to obtain a mixture.

[0086] 5. Send the mixture into the granulator to obtain garbage granules, which are rod-shaped materials with a length of 30mm and a diameter of 10mm.

[0087] 6. Drying and crushing the red mud to obtain red mud particles, the particle size of the red mud particles is 50 mm.

[0088] 7. The furnace bottom speed of the pyrolysis furnace is 1h / r, and the furnace pressure is 200Pa (relative pressure); after the r...

Embodiment 2

[0097] 1. The garbage is sent to the trommel screen for screening, and the slag, sand and other inorganic substances in the garbage are screened out from the sieve holes to obtain the screened garbage.

[0098] 2. Send the screened garbage to the magnetic separator to obtain magnetically separated garbage after metal removal.

[0099] 3. Send the magnetically separated garbage into the crusher, and obtain broken garbage after crushing. The particle size of the broken garbage is 10mm.

[0100] 4. Mix the crushed garbage and additives in a kneader to obtain a mixture.

[0101] 5. Send the mixture into the granulator to obtain garbage granules, which are rod-shaped materials with a length of 30mm and a diameter of 10mm.

[0102] 6. Drying and crushing the red mud to obtain red mud particles, the particle size of the red mud particles is 40mm.

[0103] 7. The furnace bottom speed of the pyrolysis furnace is 1h / r, and the furnace pressure is 200Pa (relative pressure); after the r...

Embodiment 3

[0112] 1. The garbage is sent to the trommel screen for screening, and the slag, sand and other inorganic substances in the garbage are screened out from the sieve holes to obtain the screened garbage.

[0113] 2. Send the screened garbage to the magnetic separator to obtain magnetically separated garbage after metal removal.

[0114] 3. Send the magnetically separated garbage into the crusher, and obtain broken garbage after crushing. The particle size of the broken garbage is 9mm.

[0115] 4. Mix the crushed garbage and additives in a kneader to obtain a mixture.

[0116] 5. Send the mixture into the granulator to obtain garbage granules, which are rod-shaped materials with a length of 30mm and a diameter of 10mm.

[0117] 6. Drying and crushing the red mud to obtain red mud particles, the particle size of which is 60 mm.

[0118] 7. The furnace bottom speed of the pyrolysis furnace is 1h / r, and the furnace pressure is 200Pa (relative pressure); after the red mud enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com