An LNG air-temperature gasification device and method for generating electricity using solar walls and temperature differences

An air-temperature gasifier and thermoelectric power generation technology, which is applied in the field of solar energy gasification of LNG, can solve the problem of low gasification capacity of the LNG air-temperature gasifier, frost and icing on the outer surface of the gasifier, and a gasification amount of up to 100%. Less than the rated value and other problems, to achieve the effect of promoting heat exchange, eliminating frost and freezing, and reducing energy consumption for gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

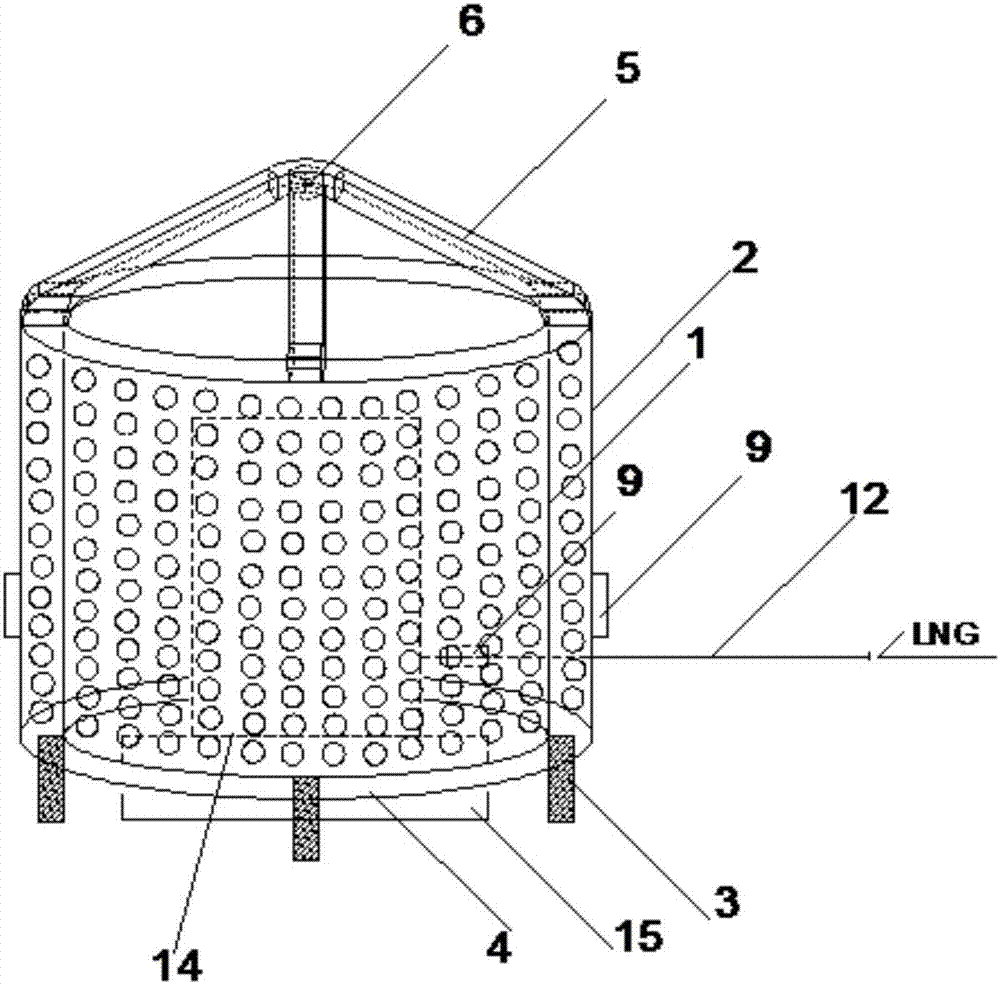

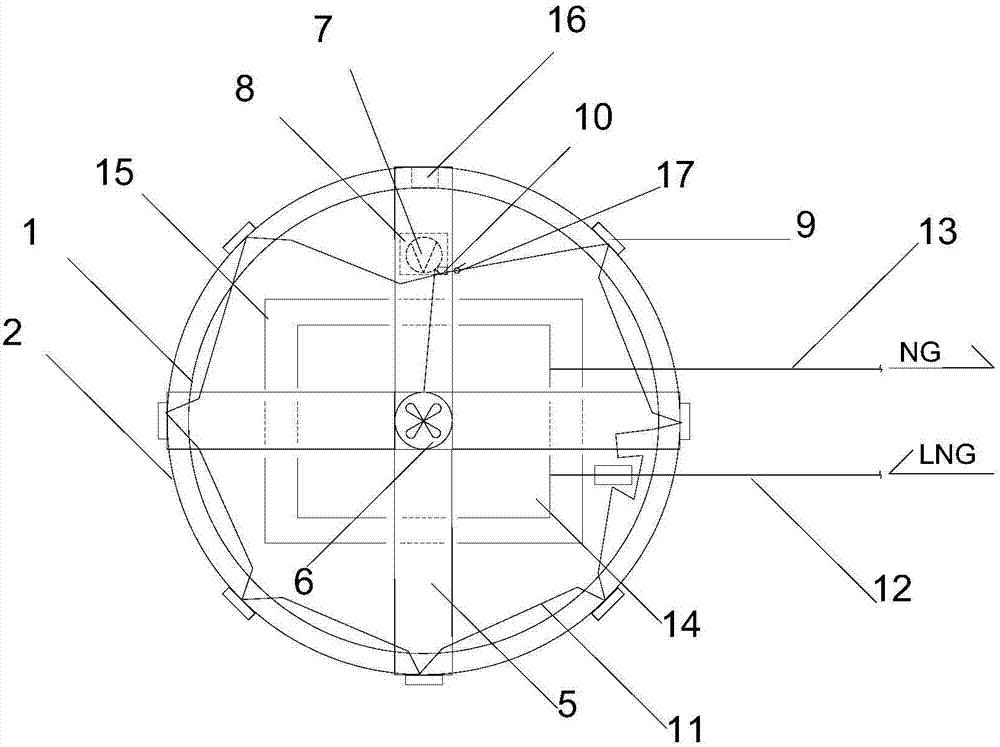

[0030] Such as Figure 1-Figure 2 Shown is an LNG air-temperature gasification device that utilizes a solar wall and a temperature difference to generate electricity. The device includes a solar wall, a thermoelectric power generation sheet 9, a fan 6, an air pipe 5, a motor 7, and an LNG air-temperature gasifier 14;

[0031] The solar wall is a cylindrical structure, including a solar wall inner panel 1 and a solar wall heat collecting plate 2 from the inside to the outside, and the solar wall inner plate 1 and the solar wall heat collecting plate 2 are made of galvanized steel, both The bottom of the solar wall is flush with the tops of the two, and the two are separated to form a solar wall cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com