A device for improving the gasification capacity of lng air-temperature gasifier by using solar wall

An air-temperature vaporizer and solar wall technology, which is applied to solar thermal devices, solar thermal energy, solar thermal power generation, etc., can solve the problem of low vaporization capacity of LNG air vaporizer and frost on the outer surface of the vaporizer. The problems of icing and gasification have a great influence, so as to eliminate the phenomenon of frost and icing, reduce energy consumption and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

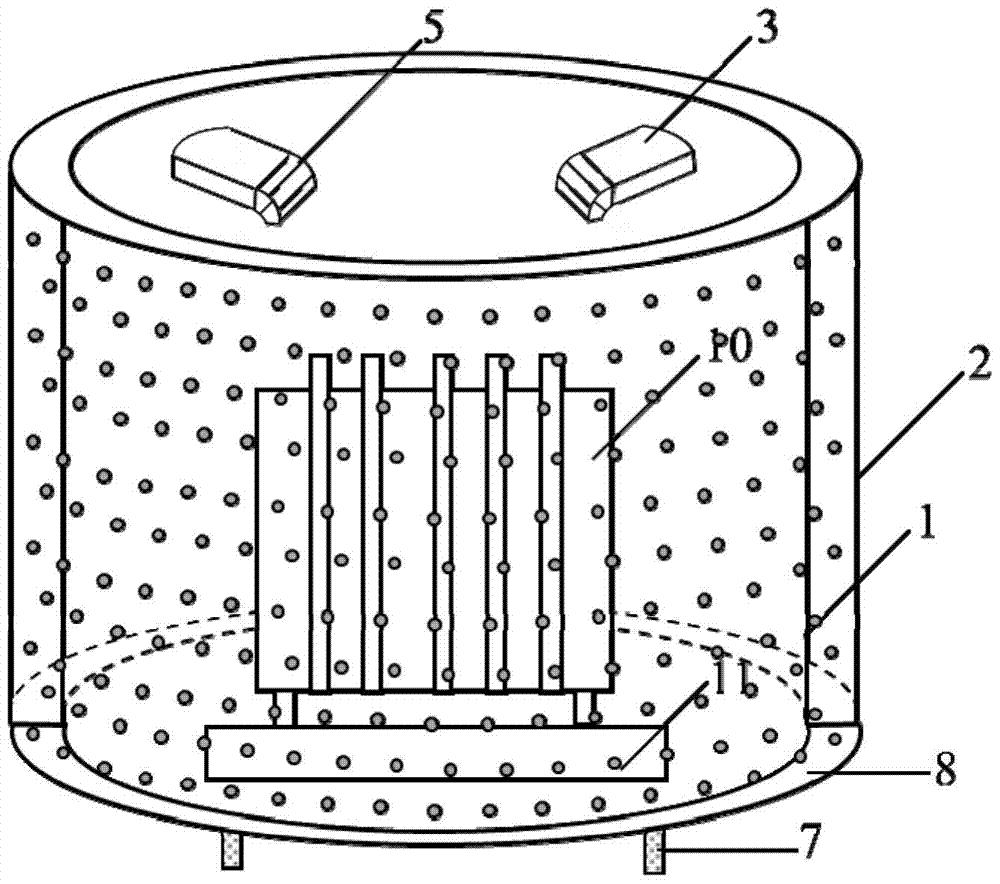

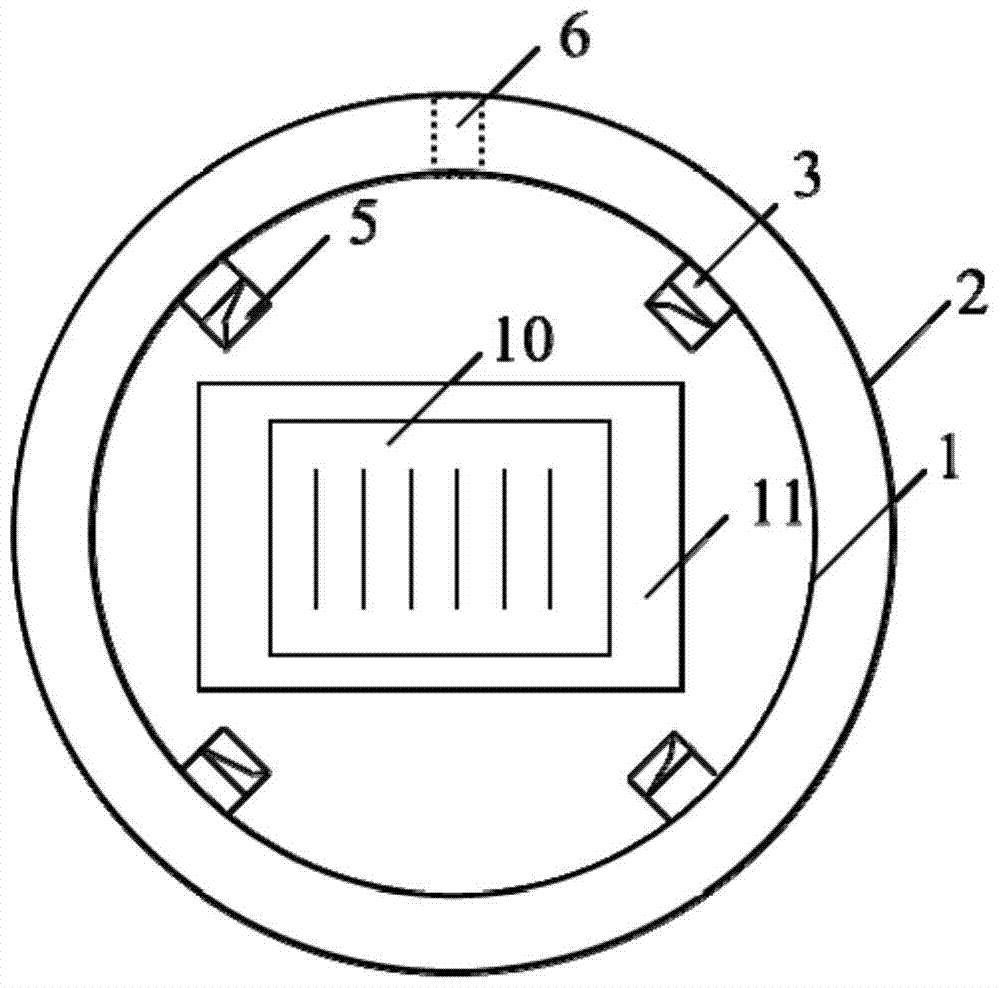

[0032] Such as Figure 1 to Figure 4 As shown, the present invention proposes a device for improving the gasification capacity of an LNG air-temperature gasifier by using a solar wall, including: a solar wall, a tuyere 3, an inspection door 6, and an LNG air-temperature gasifier 10;

[0033] The solar wall is a cylindrical structure, including a solar wall inner plate 1 and a solar wall heat collecting plate 2; the solar wall inner plate 1 and the solar wall heat collecting plate 2 are coaxial cylinders, and the distance between them is A number of reinforcing ribs are welded on the top, and the bottom of the two forms an annular bottom air inlet 8, and the top of the two is sealed, and the inner panel 1 of the solar wall is fixed and supported by the bottom bracket 7;

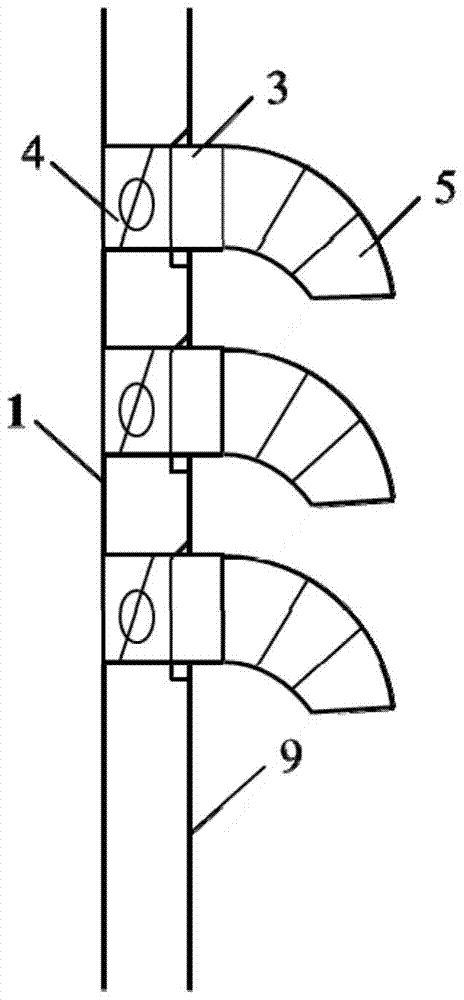

[0034] The tuyere 3 is a rectangular tuyere, opened on the solar wall inner panel 1, three layers are arranged from bottom to top, each layer is respectively provided with a tuyere in four directions of southe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com