L-shaped horizontal type rotary wave bed coal gasification production process and system

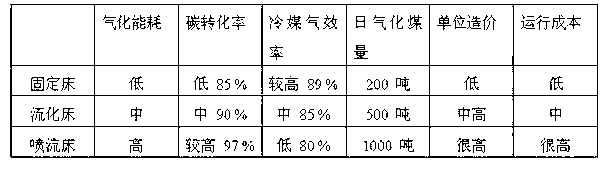

A production process and production system technology, applied in the field of L-type horizontal rotary wave bed coal gasification production process and its special coal gasification production system, can solve the problem of stable bed, low energy consumption, large daily gas production of spouted bed, and equipment operation Difficult to control and other issues to achieve the effects of low energy consumption, low operating costs, and long equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

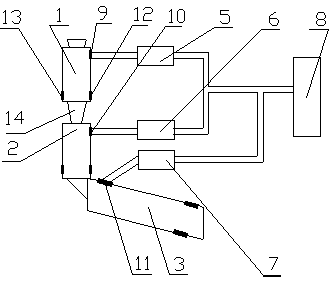

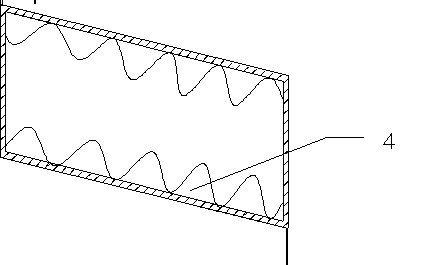

[0033] like figure 1The L-shaped horizontal rotary wave bed coal gasification production system shown includes three gasifiers connected in sequence. The first-stage gasifier 1 is a vertical Furnace 2 is a vertical gasifier mainly used to precipitate tar in coal, and gasifier 3 is a horizontal rotary furnace for full gasification of coal; among them, the bottom of the first gasifier and the second gasifier The top of the gasifier is connected, the bottom of the secondary gasifier is connected with the top of the third-stage gasifier, the top of the third-stage gasifier is higher than the bottom, and can form an angle of 5 to 25° with the ground, and the angle can be adjusted according to the gasification The amount of coal is properly adjusted; the top and bottom of each stage of the gasifier are equipped with a pressure lock 14, which can not only adjust the flow of coal, but also connect the stages of the gasifier together. The upper part of each stage gasifier is equipped ...

Embodiment 2

[0036] Taking ordinary bituminous coal with 5500-6000 kcal as an example, the coal gasification system of Example 1 is used for coal gasification production. The three-stage horizontal gasifier forms an angle of 5°-10° with the ground, and the process includes at least the following steps:

[0037] A. Coal Staged Gasification

[0038] (1) Pulverize the bituminous coal to a particle size of 0.1-6mm, and the pulverized bituminous coal can contain 20%-30% coal powder; Add 40-50 tons of flow per hour to the primary gasifier for the first gasification, so that the volatiles in the bituminous coal can be fully analyzed; the pressure in the furnace is 10-11 kg, the temperature is 400 ° C, and the oxygen flow rate is 4000 -5000m 3 / h and water vapor flow rate is 3-3.5 tons / hour;

[0039] (2) The bituminous coal enters the secondary gasifier from the primary gasifier, where the gasification is carried out for the second time, so that the tar in the bituminous coal is fully separated...

Embodiment 3

[0044] Taking coal gangue with a coal content of 30% as an example, the coal gasification system of Example 1 is used for coal gasification production. The three-stage gasifier forms an angle of 15-25° with the ground. The process includes at least the following steps:

[0045] A. Coal Staged Gasification

[0046] (1) The gangue is crushed to a particle size of 0.1-6mm, and the crushed gangue can contain 20%--30% coal powder; then the crushed gangue is gasified at a daily rate of 3,000 tons / day According to the flow rate of 120-140 tons per hour, it is added to the primary gasifier for the first gasification, so that the volatile matter in the coal gangue can be fully analyzed; the pressure in the furnace is 10 kg, the temperature is 400-450 ° C, and the oxygen flow rate is 8000-9000m 3 / h and water vapor flow rate is 6-6.5 tons / hour;

[0047] (2) Coal enters the secondary gasification furnace from the primary gasification furnace, and is gasified for the second time in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com