System and method for treating solid waste

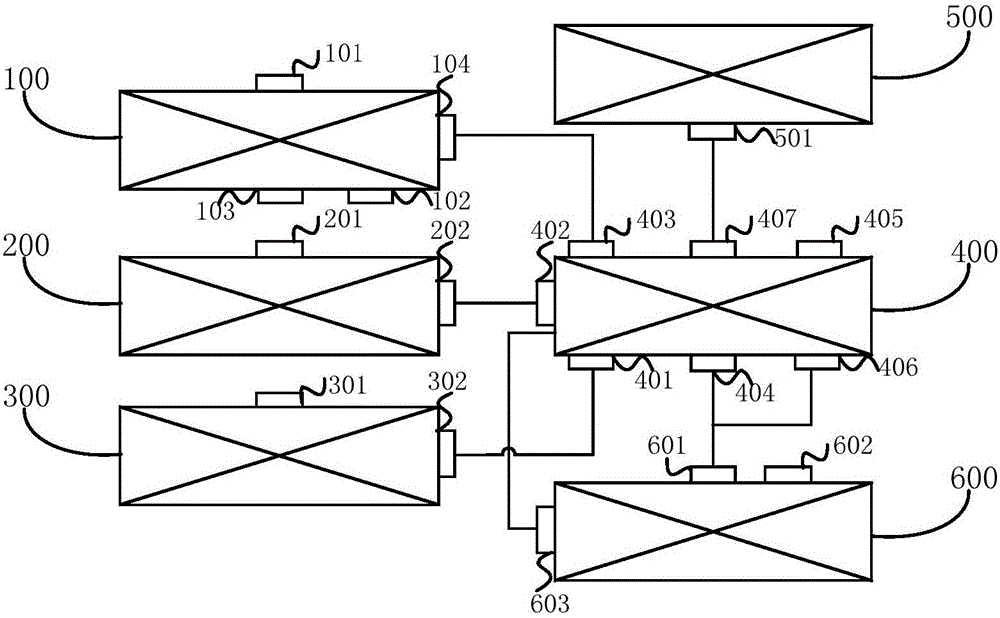

A technology of solid waste and pretreatment unit, which is applied in the field of solid waste resource treatment, and can solve problems such as low pyrolysis temperature, difficulty in industrialization, and complex system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

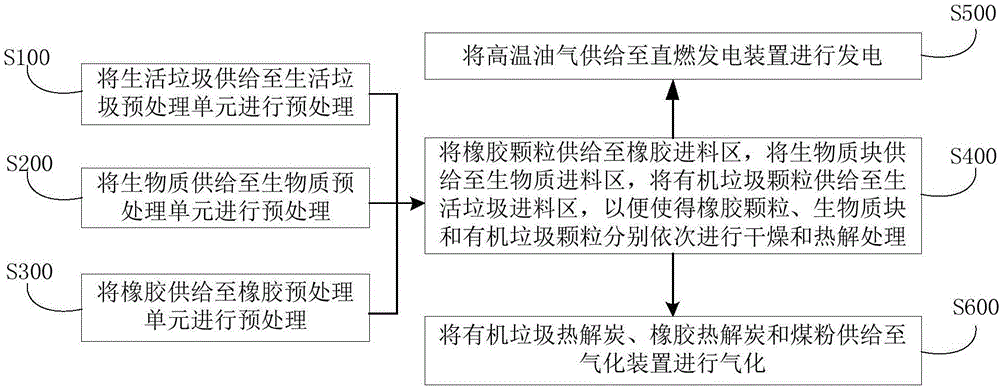

[0112] refer to Figure 4 , the domestic waste with a moisture content of 55wt% (the composition of domestic waste is shown in Table 1) is supplied to the domestic waste pretreatment unit through sorting, magnetic separation, crushing and heap filtration in order to obtain inorganic waste, heap filtrate and Organic waste particles with a moisture content of less than 40wt%; the biomass with a moisture content of 10wt% is supplied to the biomass pretreatment unit through slicing, crushing and briquetting in order to obtain biomass blocks; the moisture content is 2% The rubber is supplied to the rubber pretreatment unit for crushing treatment to obtain rubber granules.

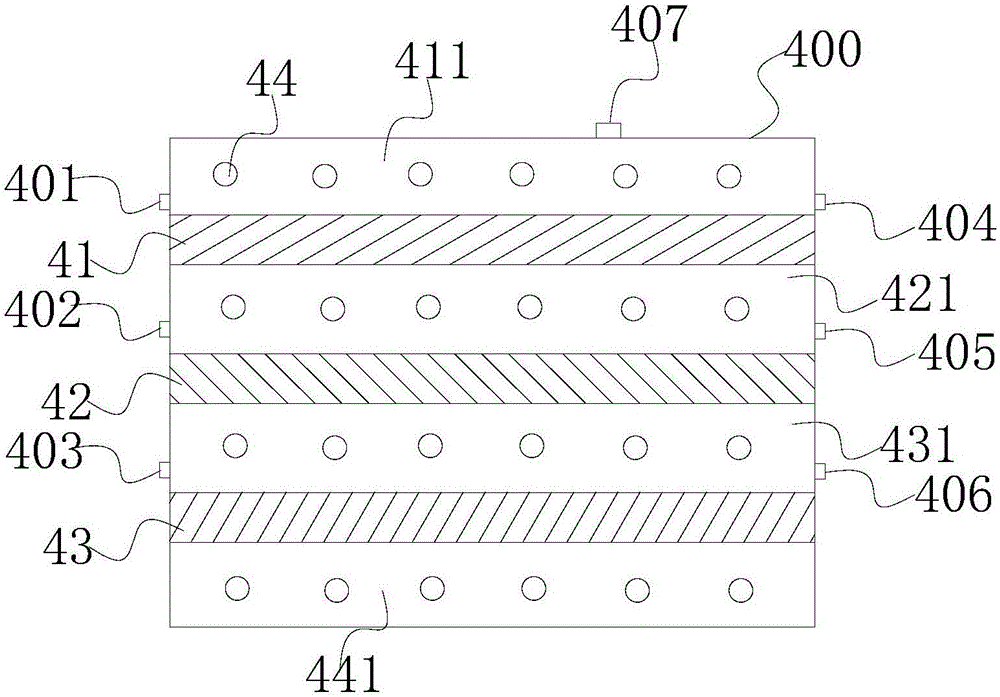

[0113] The main equipment for pyrolysis is a rotary bed pyrolysis furnace, which includes: rubber pyrolysis furnace bottom, biomass pyrolysis furnace bottom and domestic waste pyrolysis furnace bottom, rubber pyrolysis furnace bottom, biomass pyrolysis furnace The bottom and the domestic waste pyrolysis furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com