Biomass oil preparing process and device

A technology of biomass oil and preparation process, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, biofuels, etc., and can solve the problems of difficult temperature control, small production scale, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

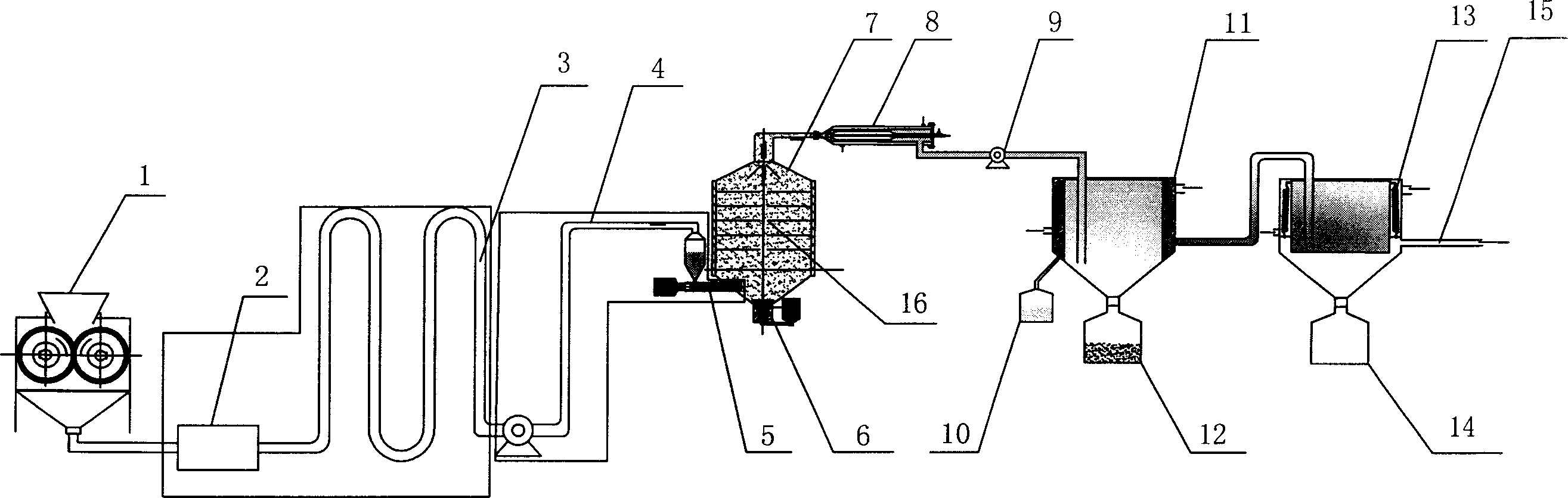

[0035] An embodiment will be given below to further describe the present invention in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

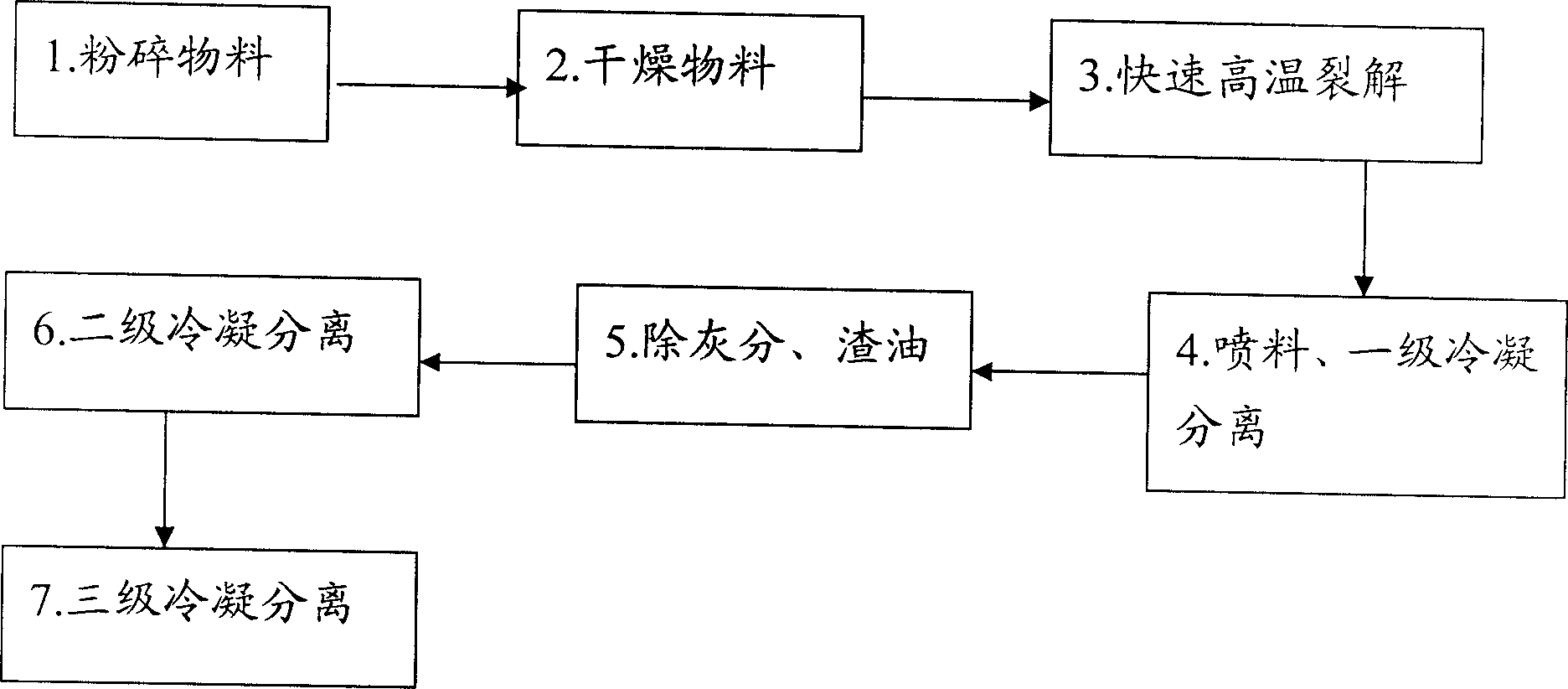

[0036] like figure 1 Shown, a kind of preparation technology of biomass oil comprises the following steps:

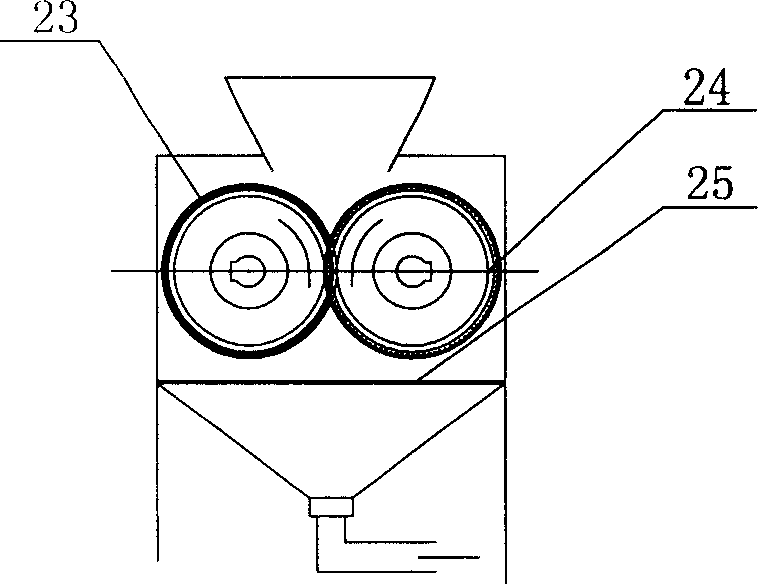

[0037] (1) crushing the biomass material into powder particles with a particle size less than 2mm;

[0038] (2) drying the obtained material particles at 100-200°C;

[0039] (3) subjecting the dried material particles to a cracking reaction at 420-650° C. under anoxic conditions;

[0040] (4) cooling the cracked product once to 200-240°C;

[0041] (5) Separating the cooled pyrolysis product, removing ash and residual oil in the product;

[0042] (6) Carry out secondary cooling to 15-30 ℃ to the product after removing ash and residual oil, collect biomass oil;

[0043] (7) cooling the uncondensed gas produced in (6) to -5-5°C for three times, and collecting low bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com