Method for catalytically gasifying coal

A coal catalytic gasification and catalyst technology, which is applied in the manufacture of combustible gas, bulk chemical production, petroleum industry, etc., can solve the problems of easy loss, equipment corrosion, good fluidity, etc. The effect of chemical activity and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] A typical but non-limiting embodiment of the present invention is as follows: a coal catalytic gasification method, comprising the steps of:

[0024] (1) Add Ca-containing compounds, K-containing compounds, Na-containing compounds, raw coal and water into the reactor, and mix them for 0.1-2.0 hours at a pressure of 0.1-1.0MPa and a temperature of 50-180°C to achieve simultaneous Preparation of Ca-based catalysts and coal pretreatment;

[0025] (2) Gasifying the product of step (1).

[0026] The amount of the Ca-containing compound is 2.0-15.0wt% as CaO, and the amount of the K-containing compound is calculated as K 2 CO 3 Calculated as 0.2-8.0wt%, the amount of the Na-containing compound is calculated as Na 2 CO 3 Calculated as 0.03-1.2wt%, the amount of each compound is based on the quality of raw coal, and the Ca-K-Na ternary component is the catalyst active component.

[0027] The invention generates a certain amount of ion exchange sites on the coal surface by ...

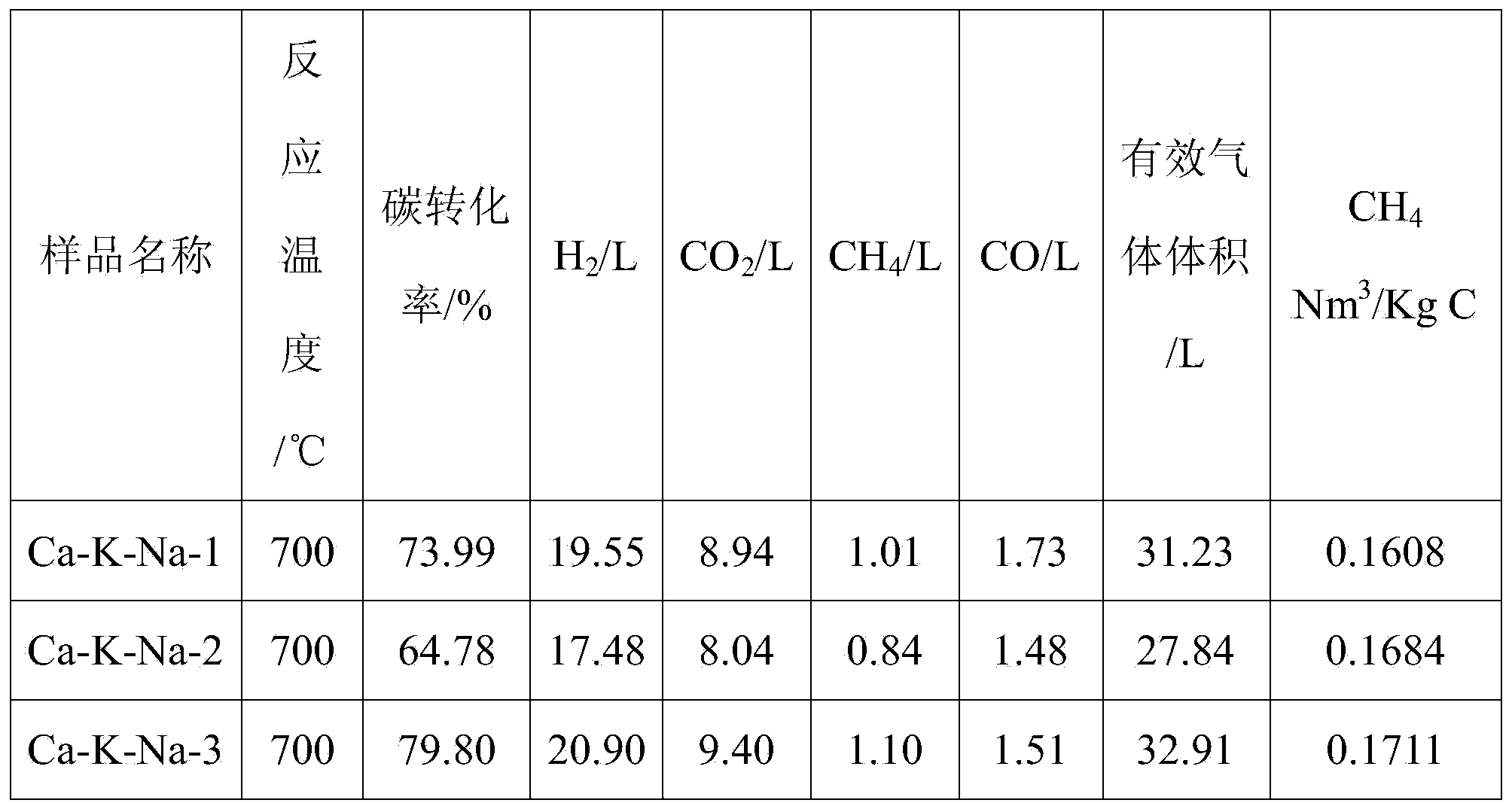

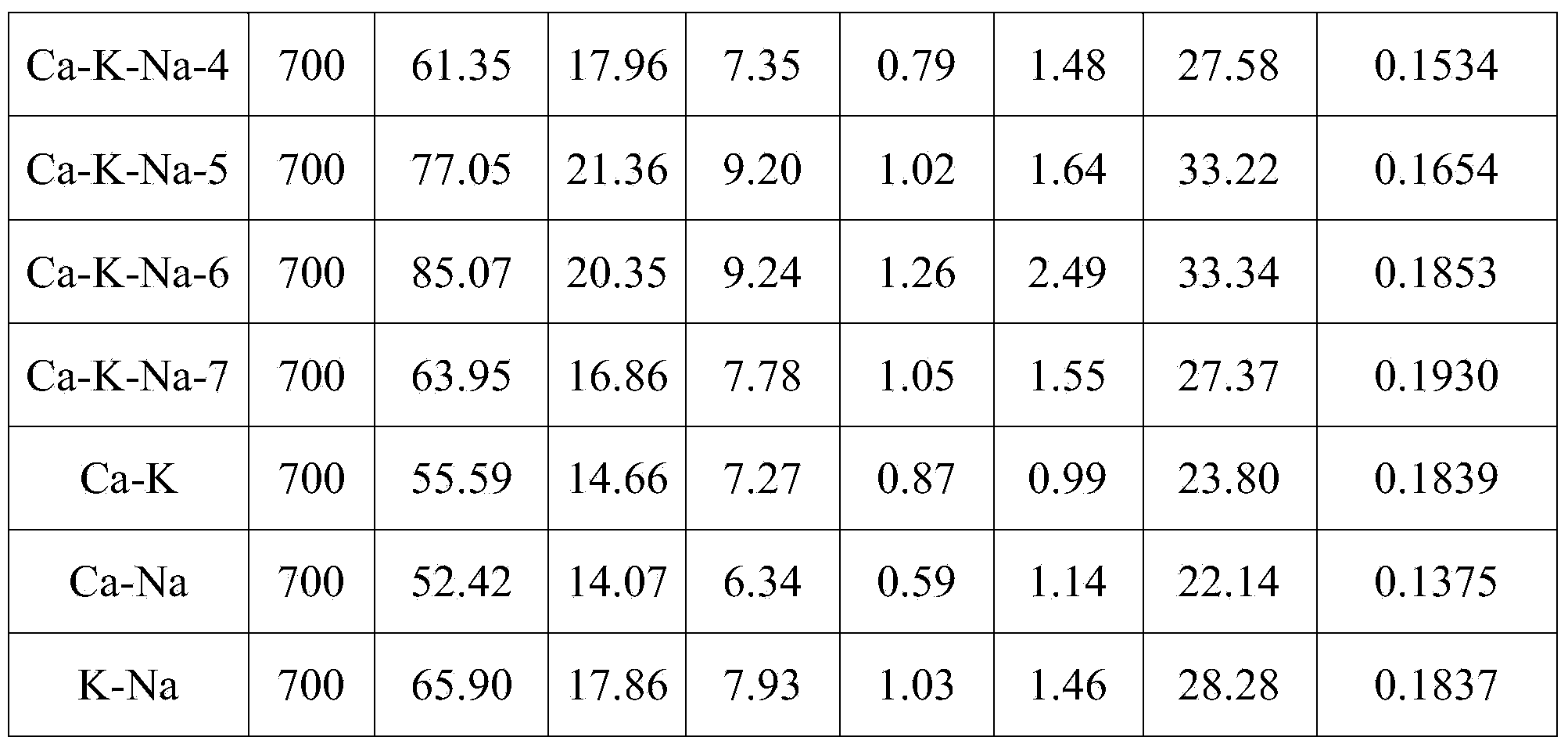

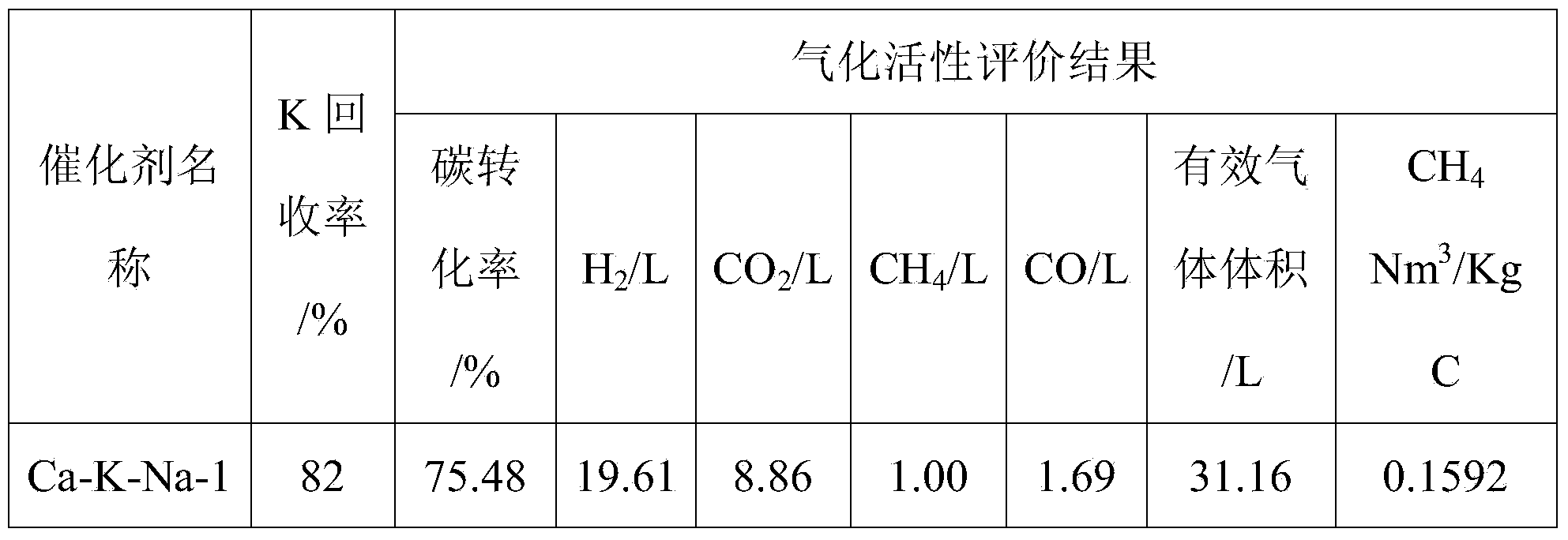

Embodiment 1

[0047] Weigh 100g of Buliangou bituminous coal, 5.0g of CaO, 0.3g of NaOH, 3.0g of KOH, and 100g of deionized water, and add them into the autoclave in sequence. Feed N into the kettle 2 , pressurize to 0.35MPa, and then raise the temperature to 90°C while stirring. After the temperature rises to the set temperature, continue to stir for 0.5h, then stop heating, and when the temperature drops to room temperature, release the pressure and pour out the coal sample. Put the coal sample in a hot air circulation drying oven at 105 ° C for 12 hours, and the sample obtained accordingly is recorded as Ca-K-Na-1. The gasification evaluation results of this sample are shown in Table 1.

Embodiment 2

[0049] Weigh 100g of Buliangou bituminous coal, 5.0g of CaO, 3.0g of KOH, 0.3g of NaOH, and 100g of deionized water, and add them into the autoclave in sequence. Then, the temperature was raised to 90° C. while stirring, and the pressure was 0.1 MPa at this time. After the temperature rises to the set temperature, continue to stir for 0.5h, then stop heating, and when the temperature drops to room temperature, release the pressure and pour out the coal sample. Put the coal sample in a hot air circulation oven and dry it at 105°C for 12 hours, and the sample thus obtained is designated as Ca-K-Na-2. The gasification evaluation results of this sample are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com